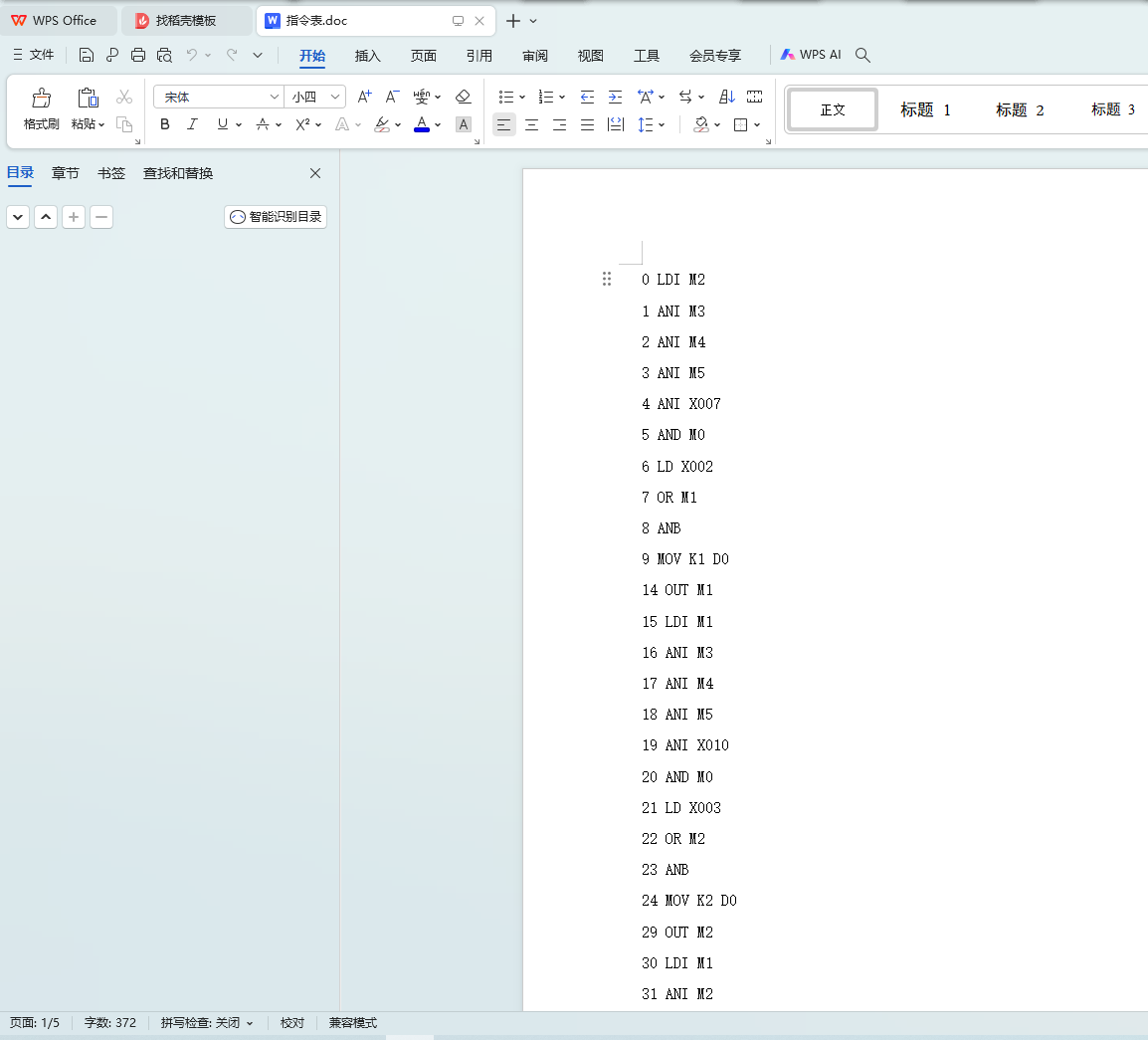

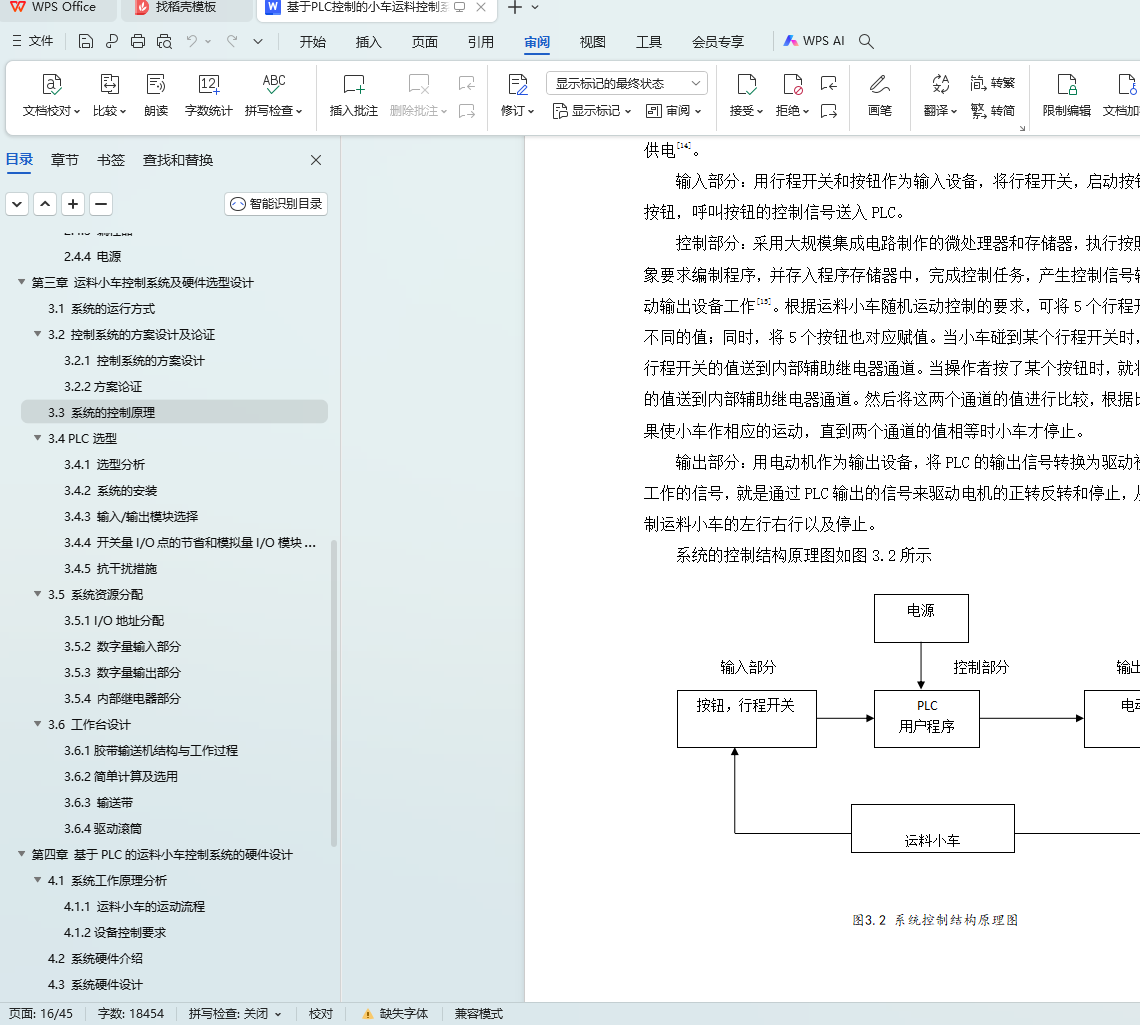

基于PLC控制的小车运料控制系统的设计 毕业论文定稿+初稿+开题报告+梯形图+指令表+cad图纸+外文翻译及原文

摘 要

近年来,随着科学技术的进步和微电子技术的迅速发展,可编程序控制技术已广泛应用于自动化控制领域,可编程序控制器(PLC)以其高可靠性和操作简便等特点,已经形成了一种工业趋势。

可编程控制器是一种新型的通用控制装置,它将传统的继电器-接触器控制技术、计算机技术和通讯技术融为一体,专门为工业控制而设计,这一新型的通用自动控制装置以其高可靠性、较强的工作环境适应性和极为方便的使用性能,深受自动化领域技术人员的普遍欢迎。

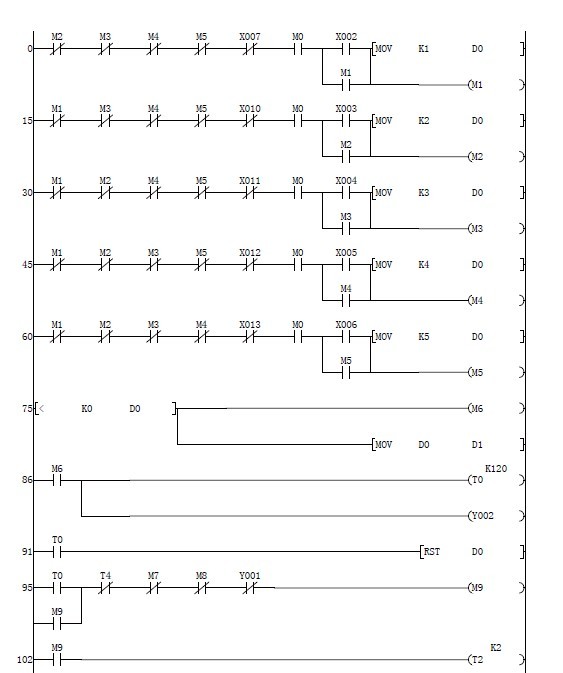

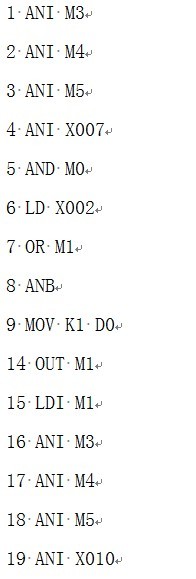

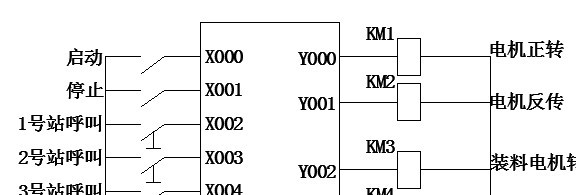

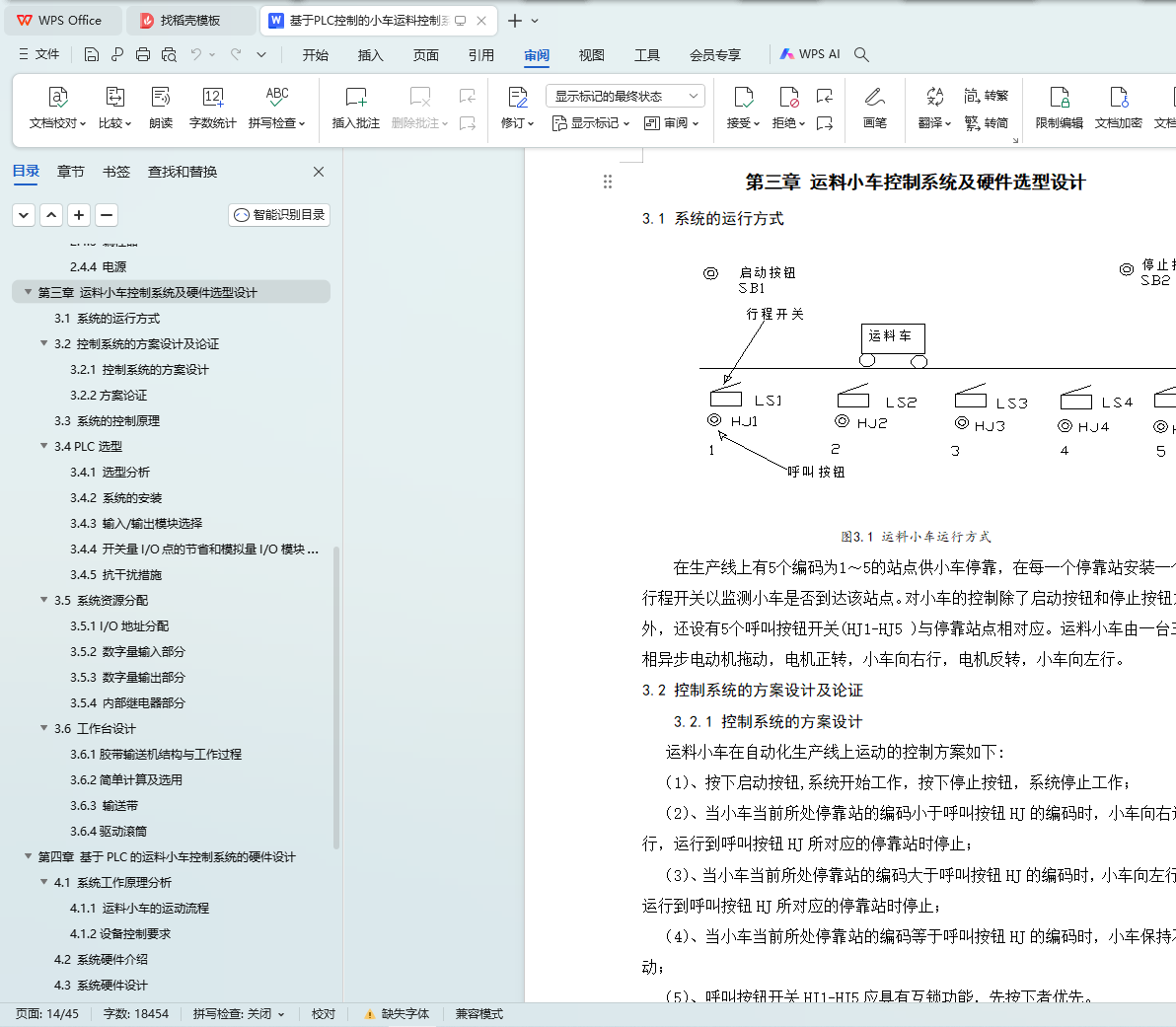

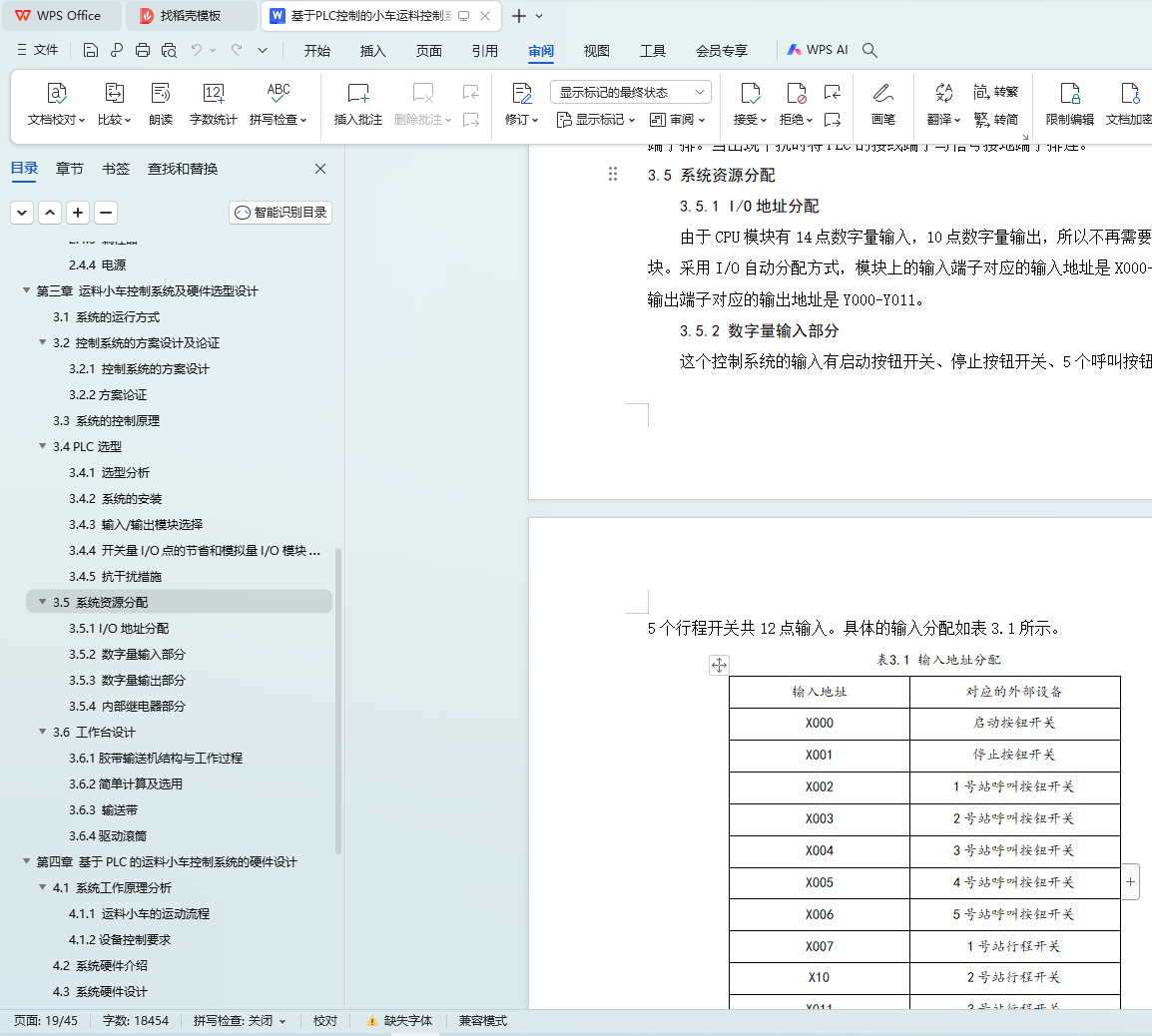

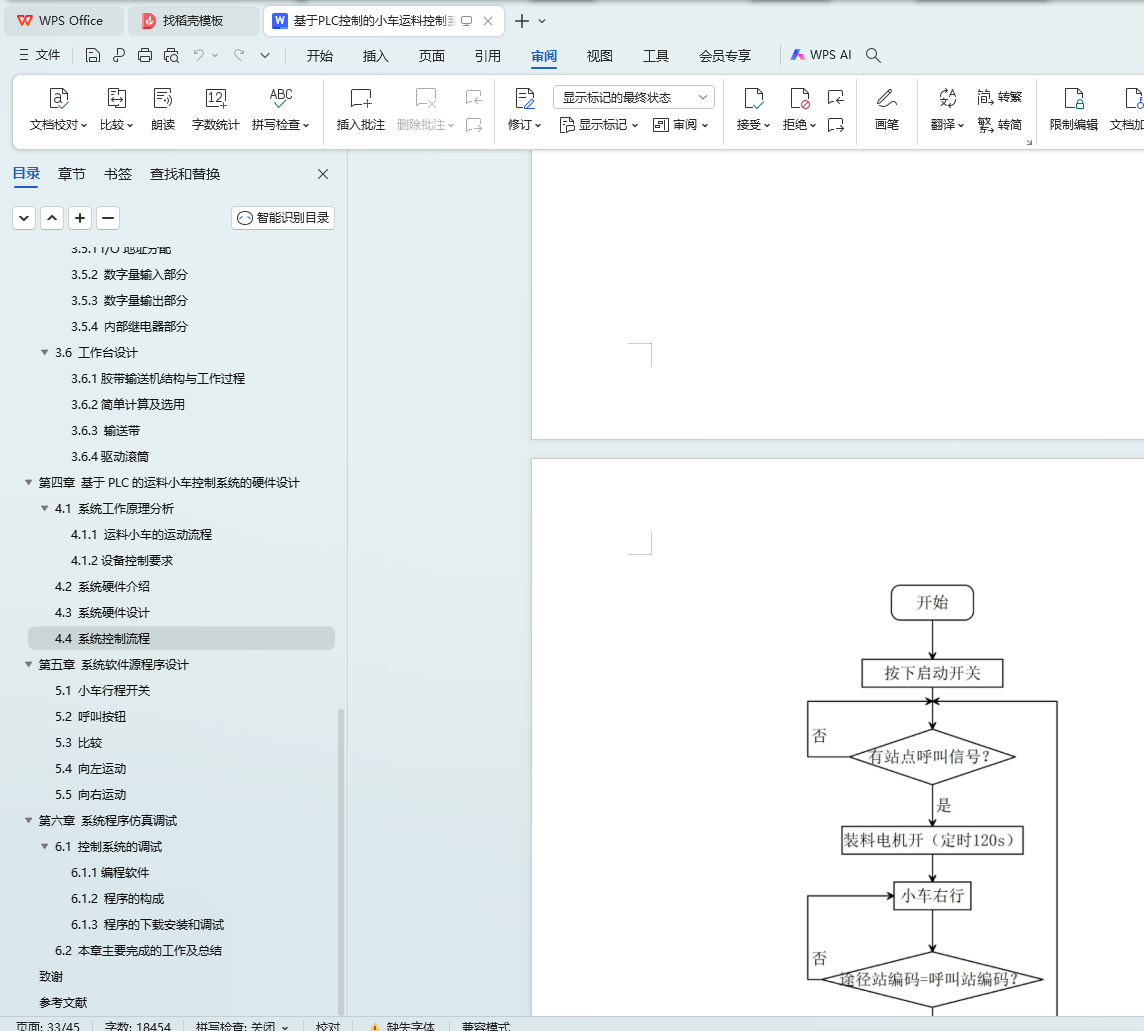

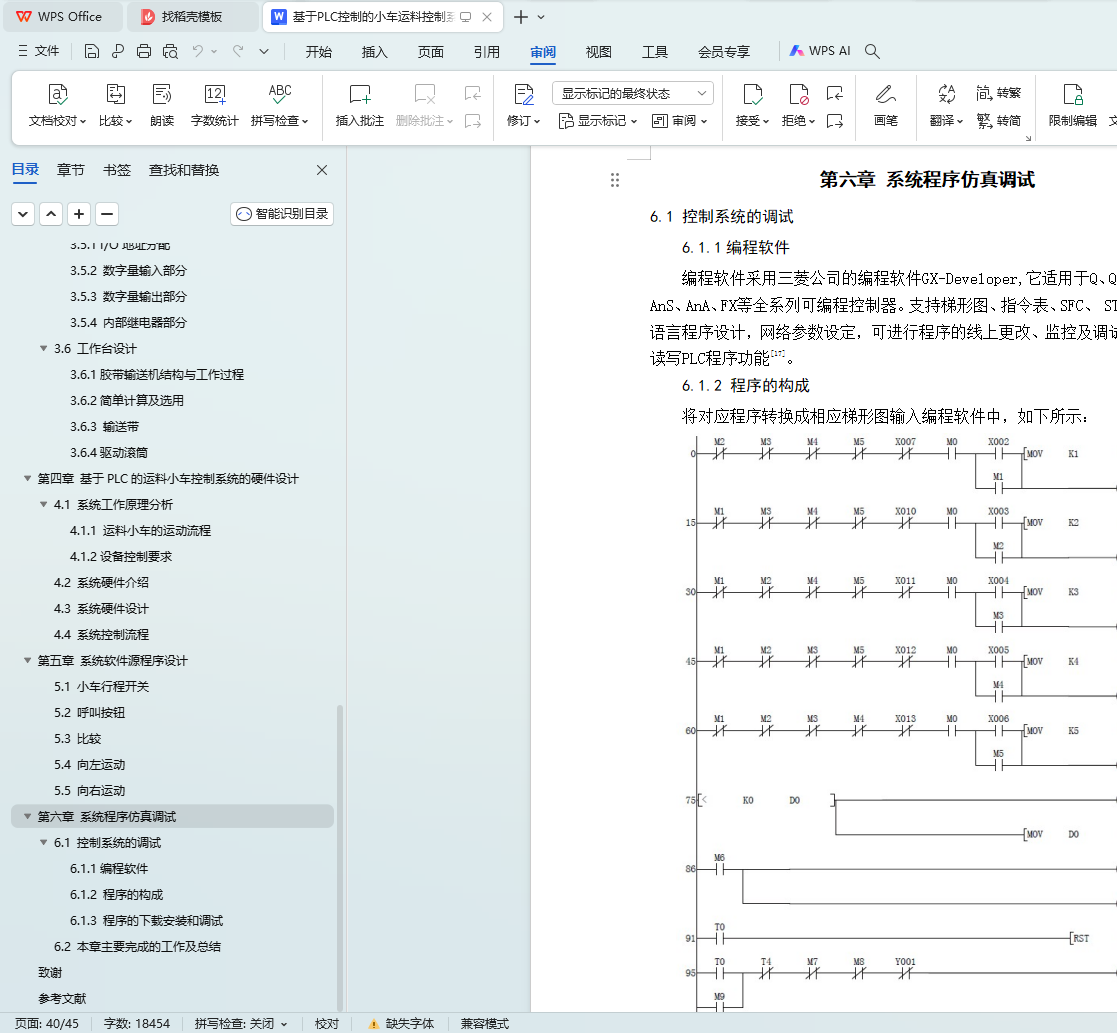

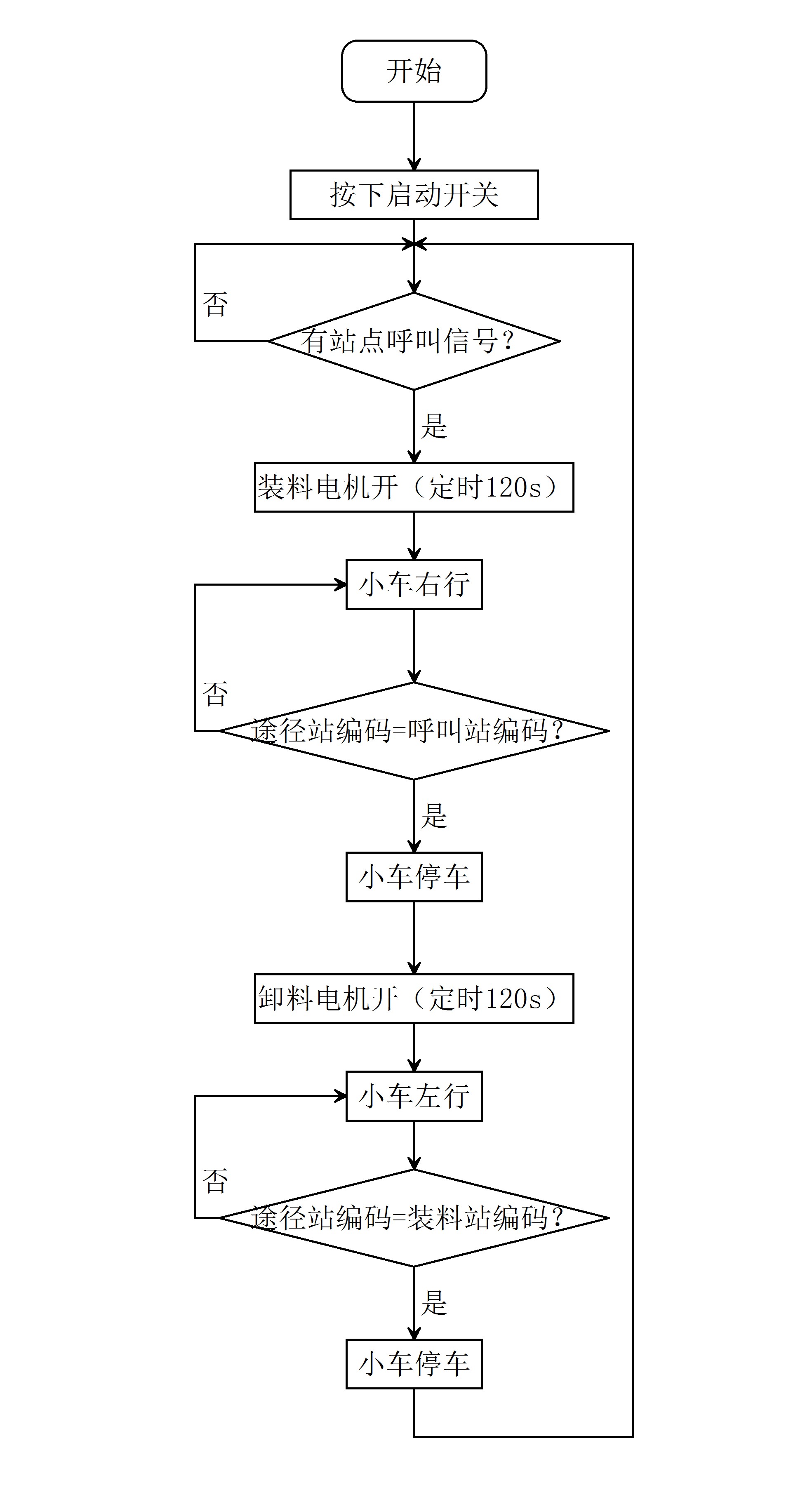

本文设计了一种由PLC控制的运料小车,该小车能在装料站完成装料过程,然后根据5个卸料站点的呼叫信号运行到相应呼叫站点进行卸料,卸料完成之后返回装料站等待下一个呼叫信号。本文对小车的控制系统经行了详细设计,其中包括硬件系统和软件系统,并结合三菱PLC编程软件GX Developer ,对系统程序经行了仿真分析。

关键词:PLC,运料小车,控制系统

ABSTRACT

In recent years, with the scientific and technological progress and rapid development of microelectronic technology, programmable control technology has been widely used in automation and control, programmable logic controller (PLC) for its high reliability and simple operation, has been formation of an industry trend.

Programmable controller is a new type of universal control devices, it will traditional relay - contactor control technology, computer technology and communication technology integration, designed specifically for industrial control, this new automatic control device to the general its high reliability, strong work environment is very easy adaptability and performance, by the automation of technical staff in general.

In this paper, a PLC control car transporter, the car in the loading station to complete the loading process, and then run according to the five discharge site call signal to the corresponding call site discharge, after the completion of the discharge Returning Assemblies feed station waits for the next call signal. The detailed design of the control system of the car line, including hardware and software systems, combined with Mitsubishi PLC programming software GX Developer, the system program line simulation analysis.

Keywords: PLC,transporter cart,control system

目 录