运料小车控制系统的设计 毕业论文+任务书+开题报告+指令表+梯形图+cad图纸

摘 要

选题“运料小车控制系统的设计”来源于实际工业应用的需求,特别是在自动化生产线、物料搬运系统以及仓储物流等领域。随着工业自动化程度的提高,对物料运输的效率和精度要求也越来越高,因此,设计一种能够高效、准确地完成物料运输任务的控制系统显得尤为重要。

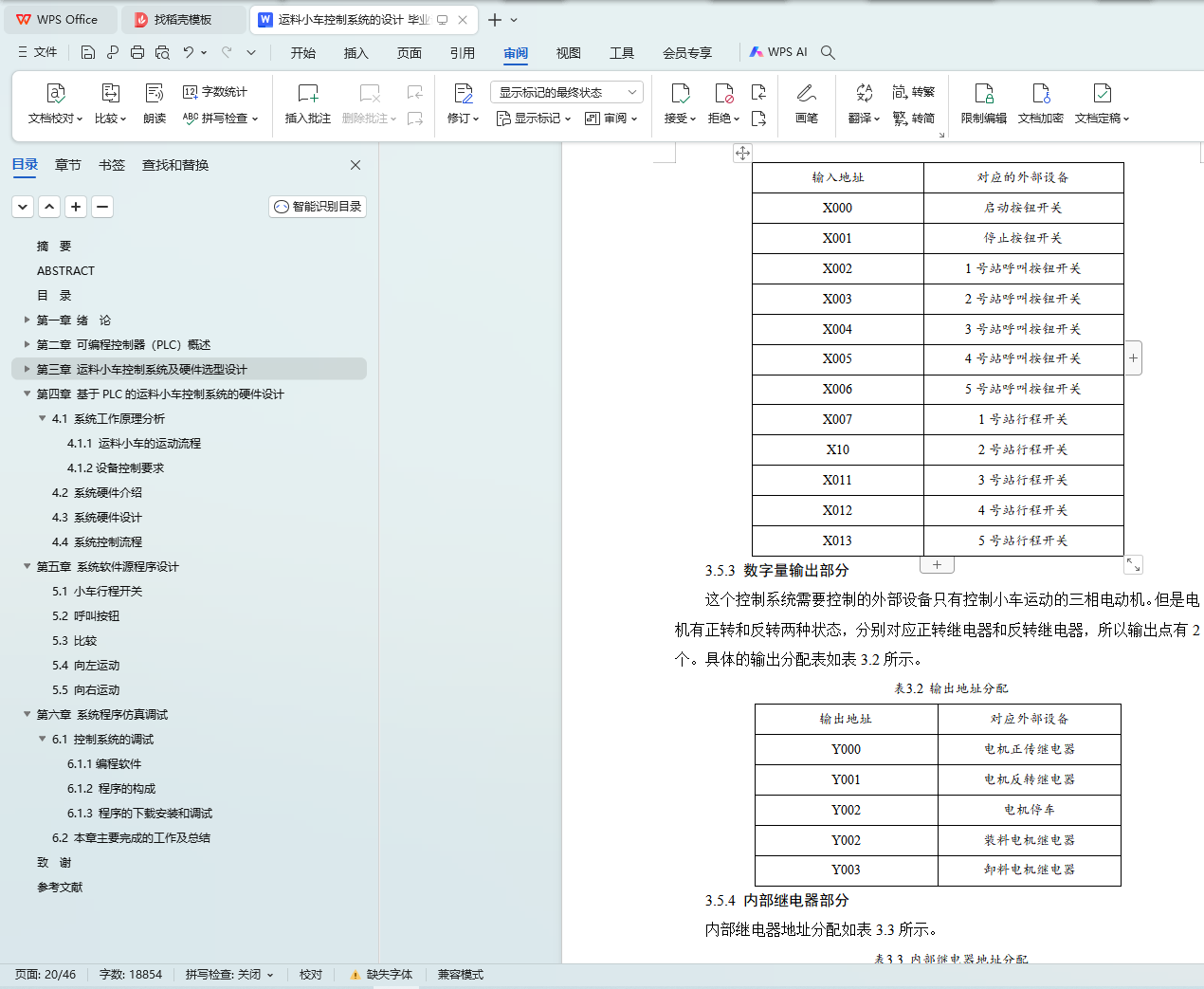

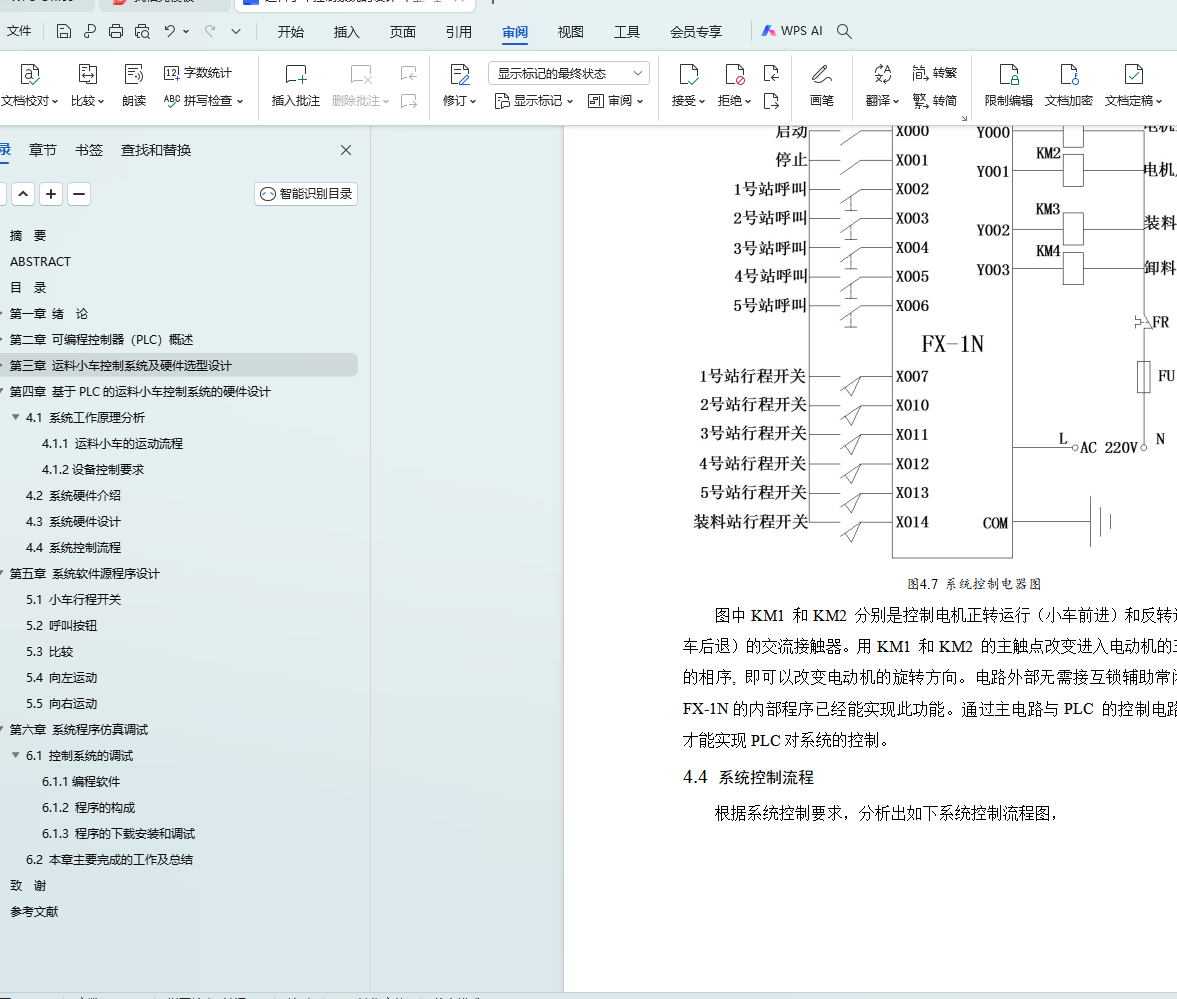

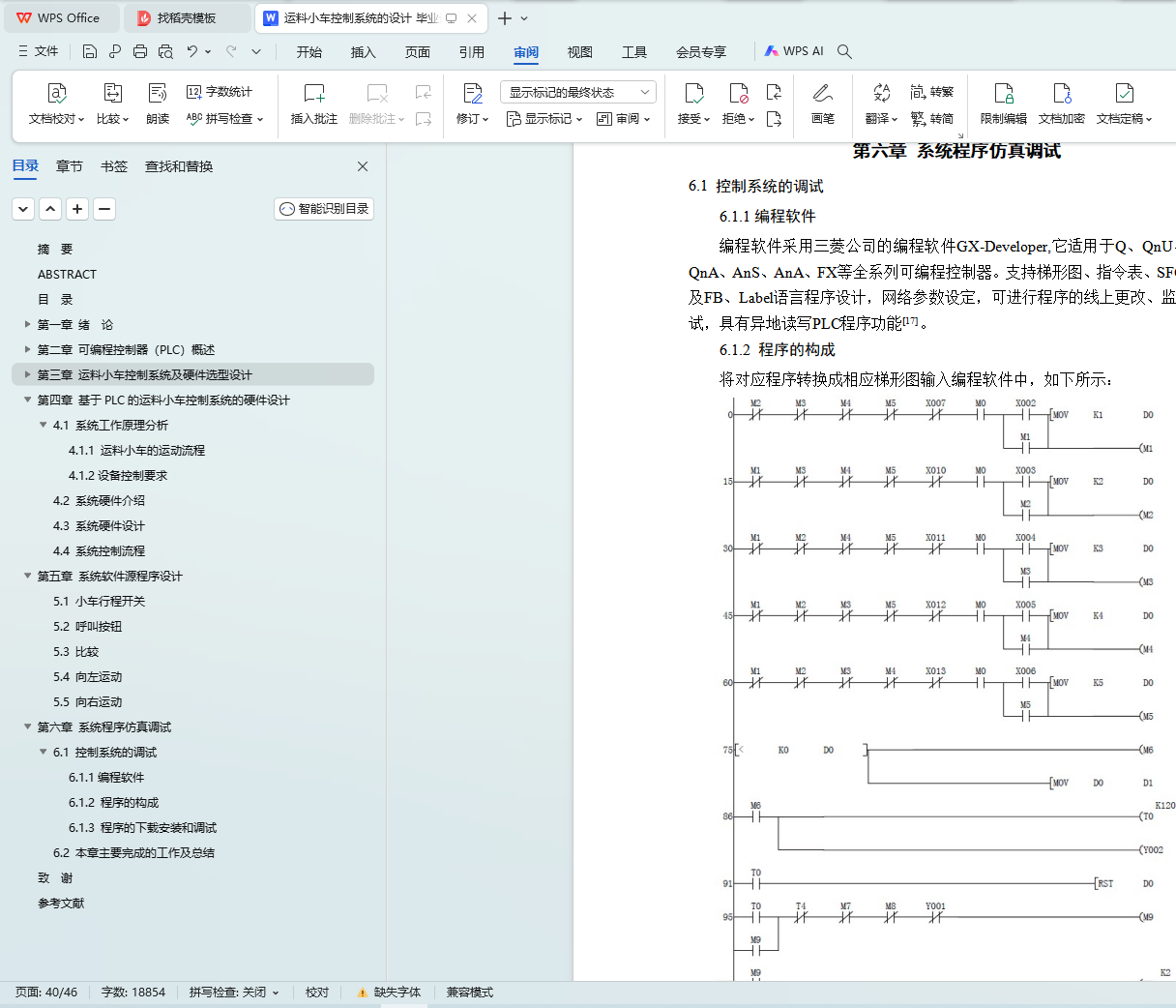

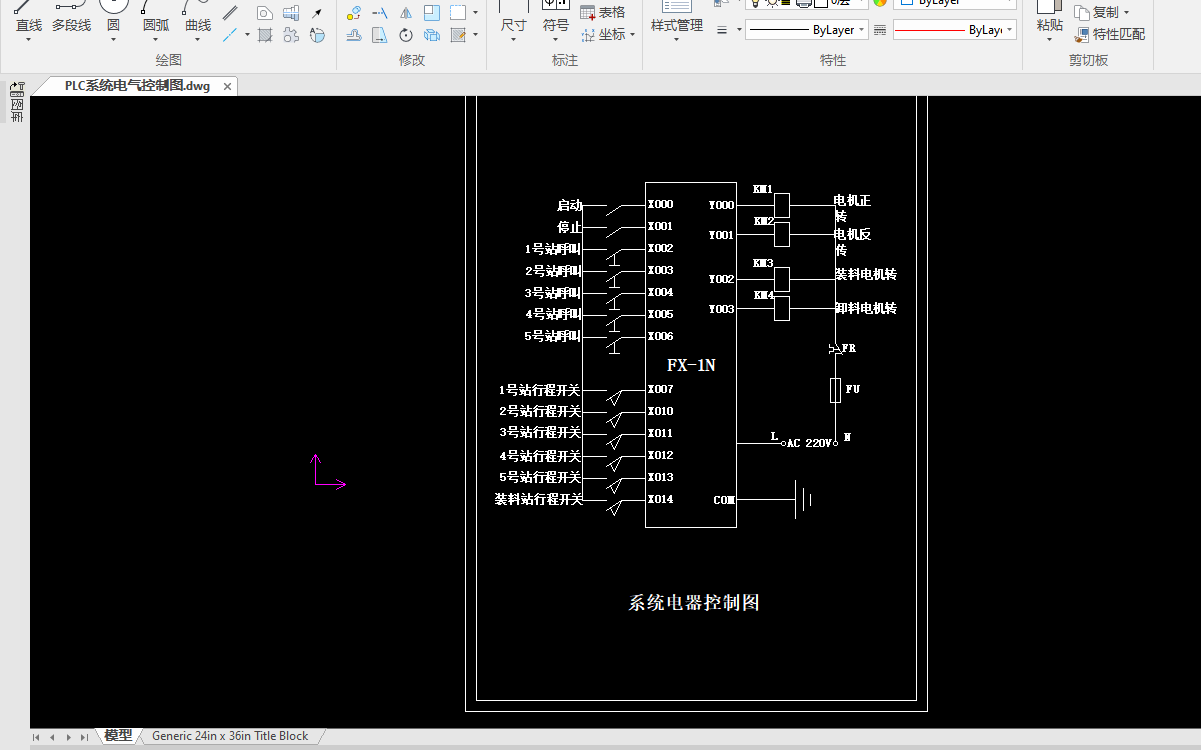

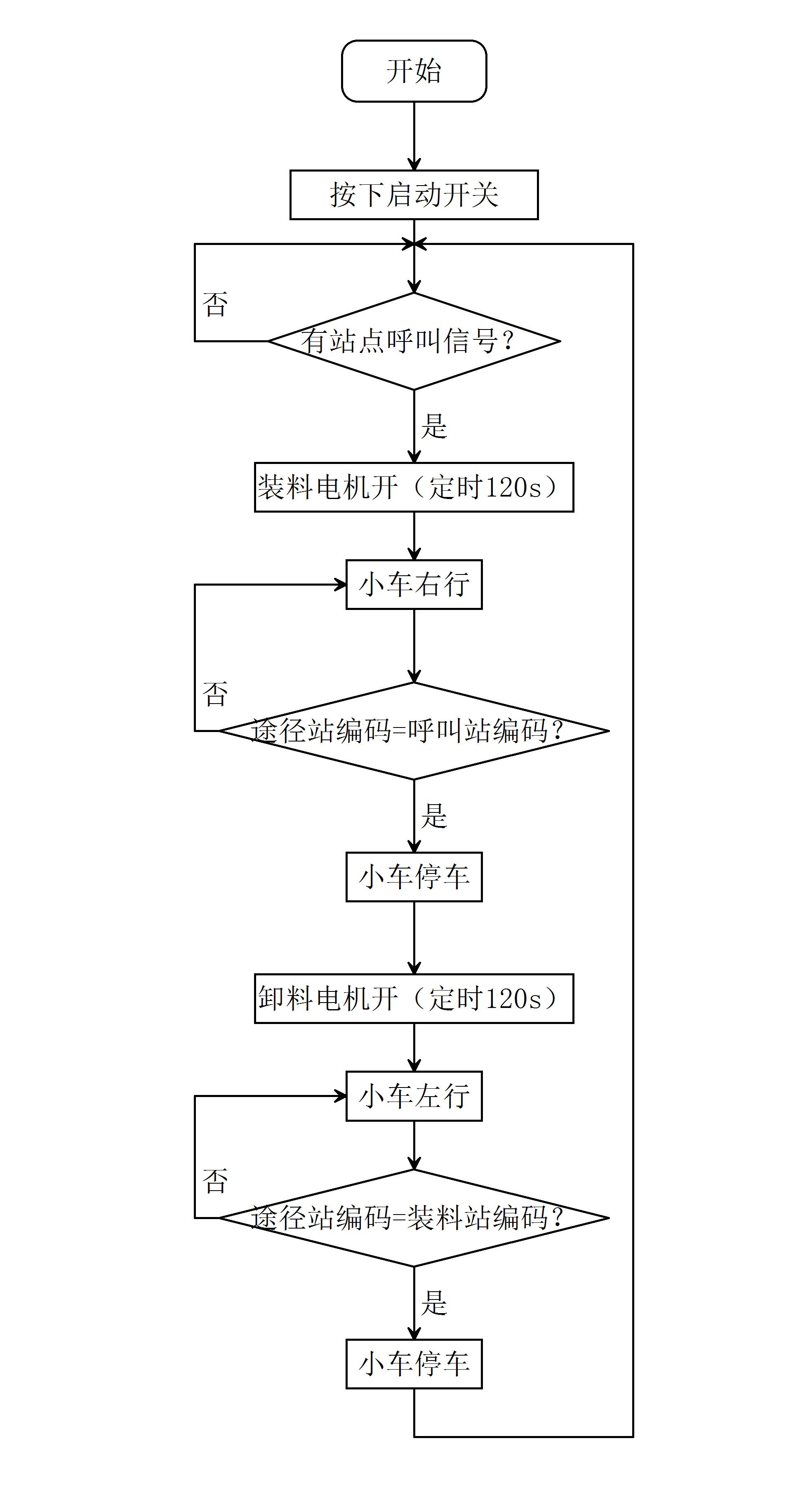

本文旨在设计并实现一个运料小车控制系统,该系统以机电一体化设计思想为基础,综合运用电气控制原理与PLC编程技术。系统通过三相异步电机驱动小车进行左右移动,并利用光电开关精准监测小车在五个停靠点的到位情况。小车具备响应呼叫按钮指令的能力,根据当前停靠站与呼叫按钮编码的对比,自动选择运行方向并精确停靠。系统设计包含电气原理图的绘制、PLC程序的编写以及系统调试等环节,旨在培养系统分析及设计的能力。实验结果表明,该系统能够实现小车的自动控制,满足运料需求,并具备良好的稳定性和可靠性。

关键词:运料小车;机电一体化;电气原理图;PLC编程;光电开关;自动控制

ABSTRACT

The topic "design of material trolley control system" comes from the needs of actual industrial applications, especially in the fields of automatic production line, material handling system and warehousing logistics. With the improvement of industrial automation, the efficiency and accuracy of material transportation are also more and more high. Therefore, it is particularly important to design a control system that can efficiently and accurately complete the task of material transportation.

This paper aims to design and realize a material transport trolley control system, which is based on the combination of electrical control principle and PLC programming technology. The system drives the car left and right through the three-phase asynchronous motor, and uses the photoelectric switch to accurately monitor the position of the car at the five docking points. The car has the ability to respond to the call button command. According to the comparison between the current stop station and the call button coding, it can automatically select the running direction and dock accurately. The system design includes the drawing of electrical schematic diagram, PLC program writing and system debugging, aiming to cultivate the ability of system analysis and design. The experimental results show that the system can realize the automatic control of trolley, meet the material demand, and have good stability and reliability.

Key words: trolley; mechatronics; electrical schematic; PLC programming; photoelectric switch and automatic control

目 录