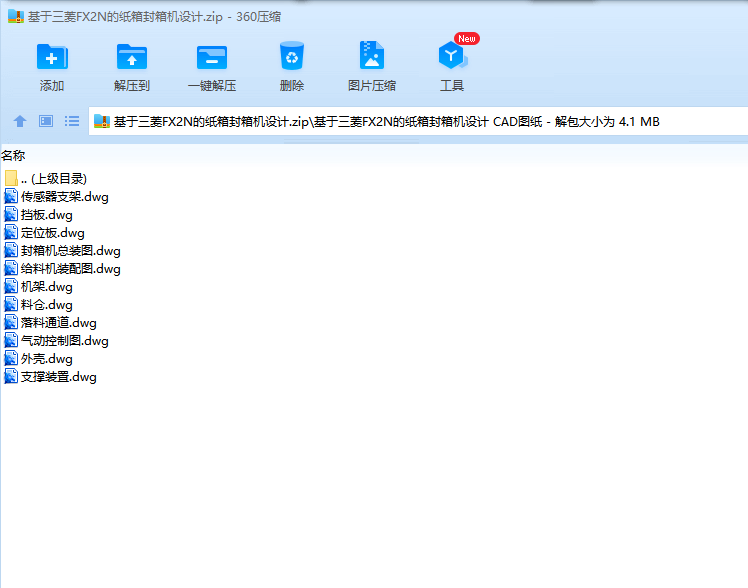

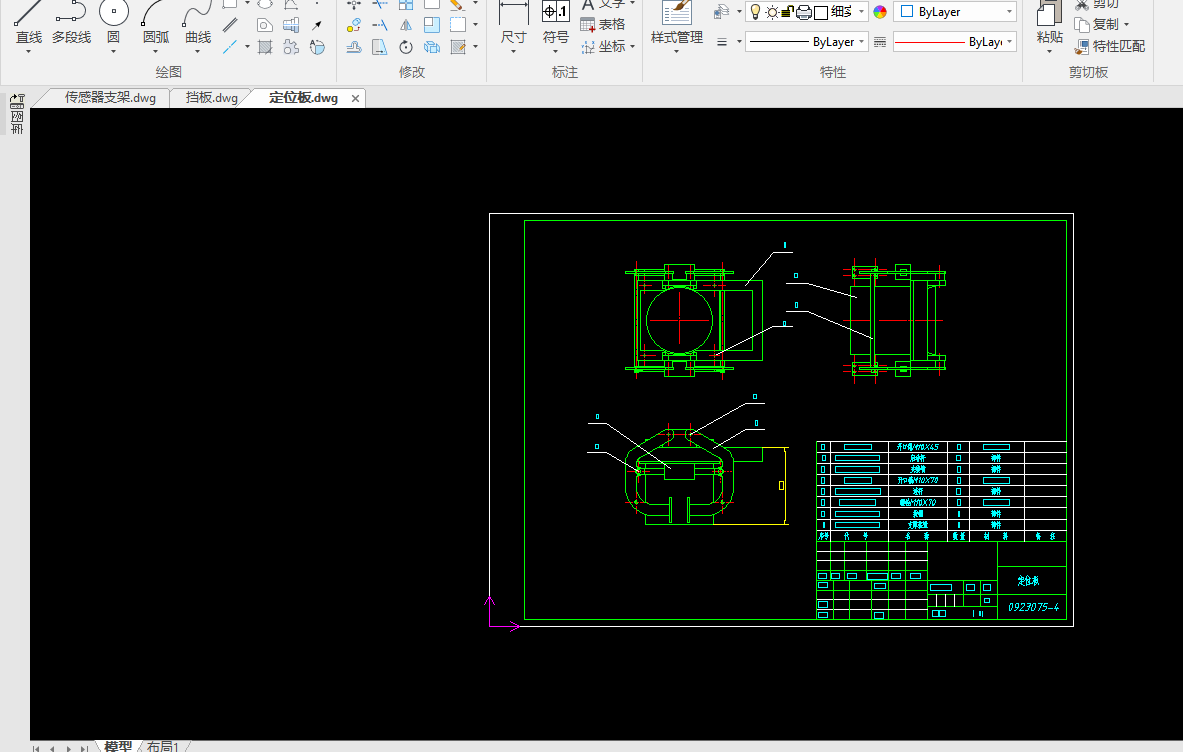

基于三菱FX2N的纸箱封箱机设计 毕业论文+任务书+开题报告+PLC梯形图+CAD图纸

目 录

摘要 III

ABSTRACT IV

目录 V

1 绪论

2.1.5 螺旋输送机安装技术条件

2.1.6 传动装置的选择 10

2.2.3 秤体结构

2.2.4 称量桶材料选择

2.2.5 称体容积选择

5.1 结论 9

致谢 30

摘 要

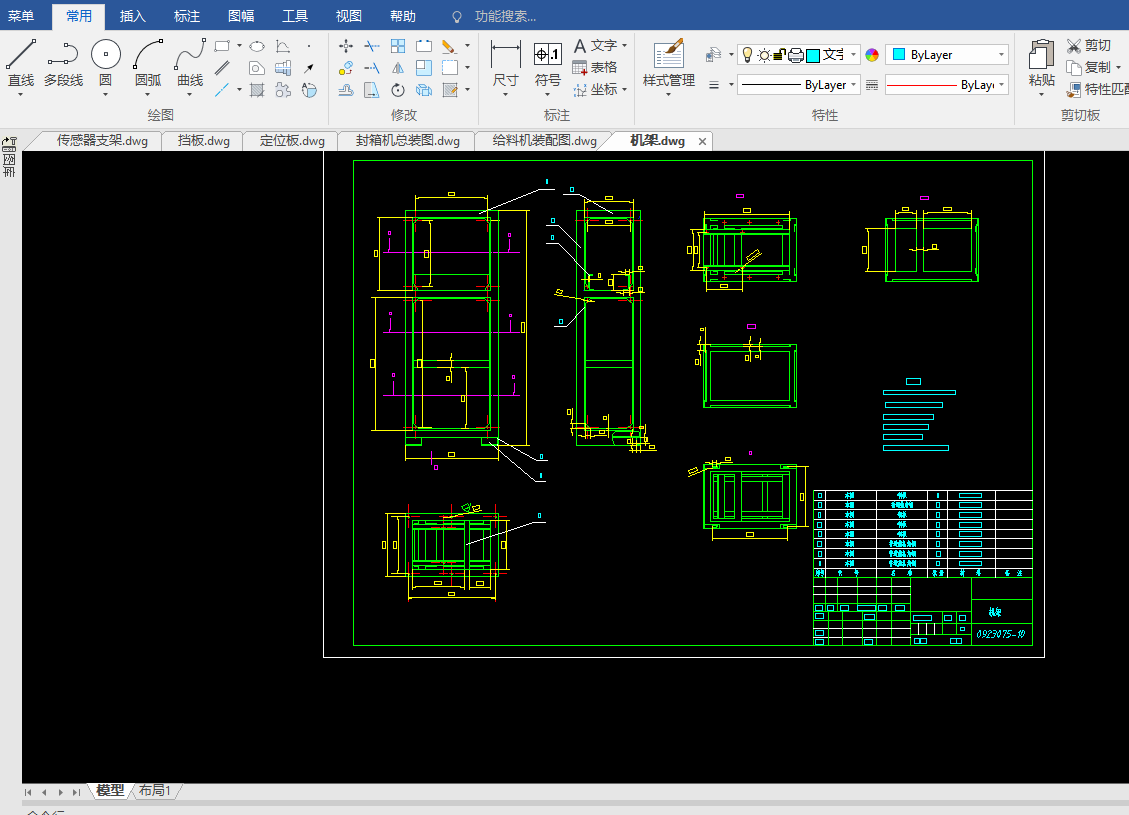

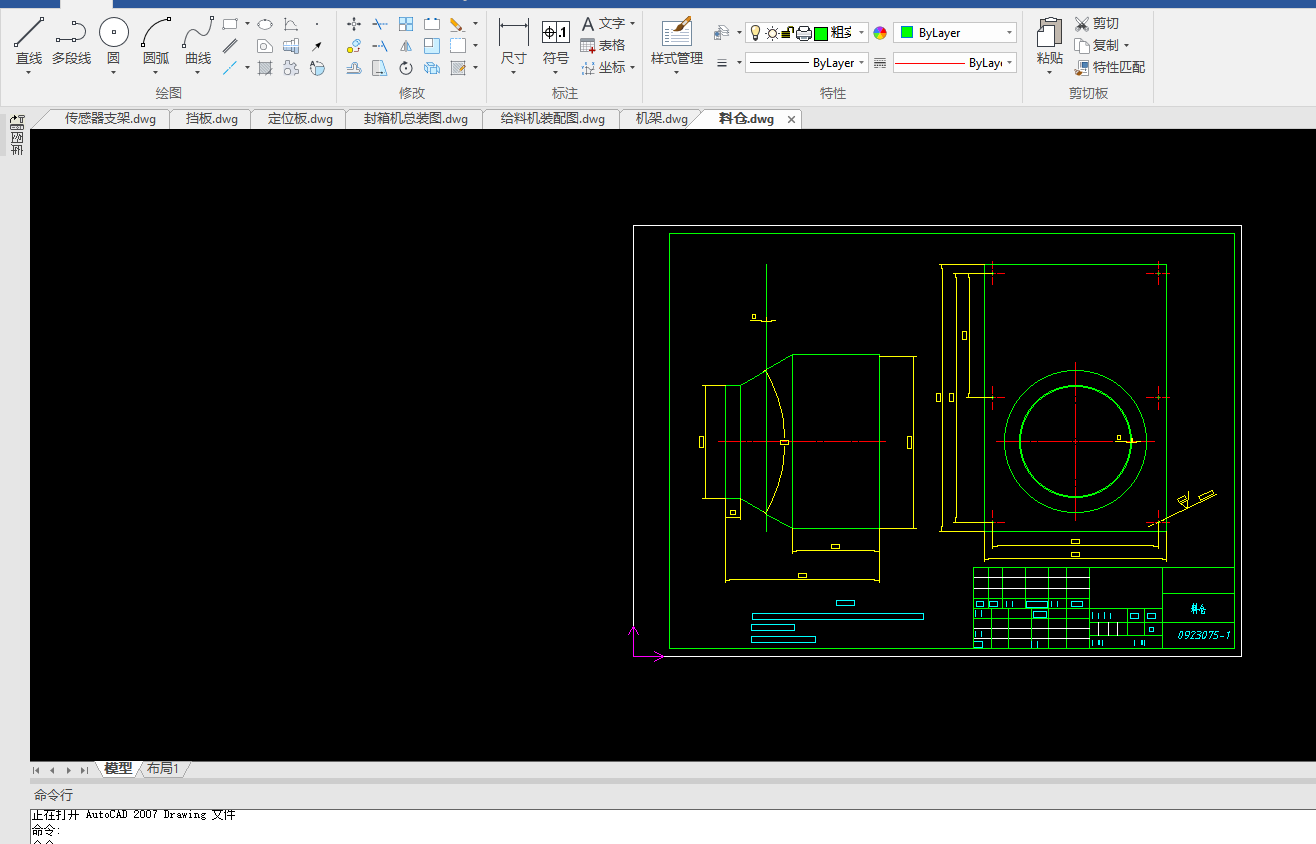

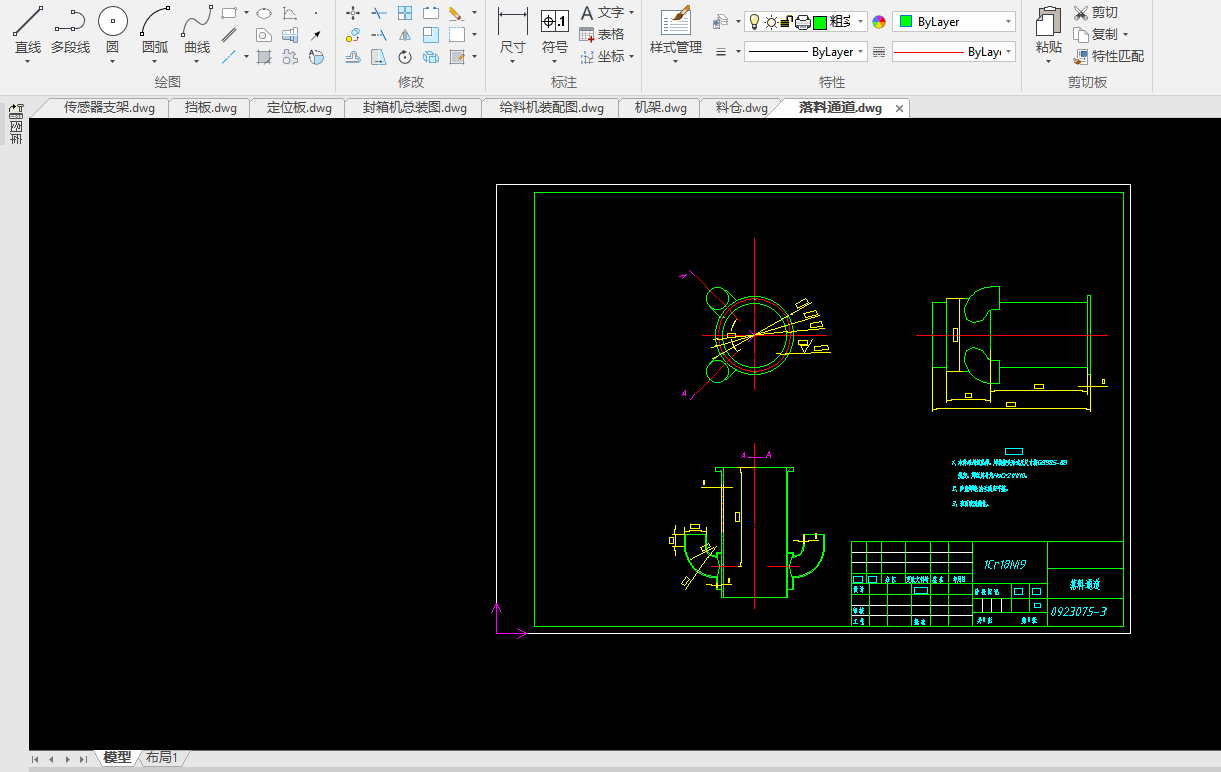

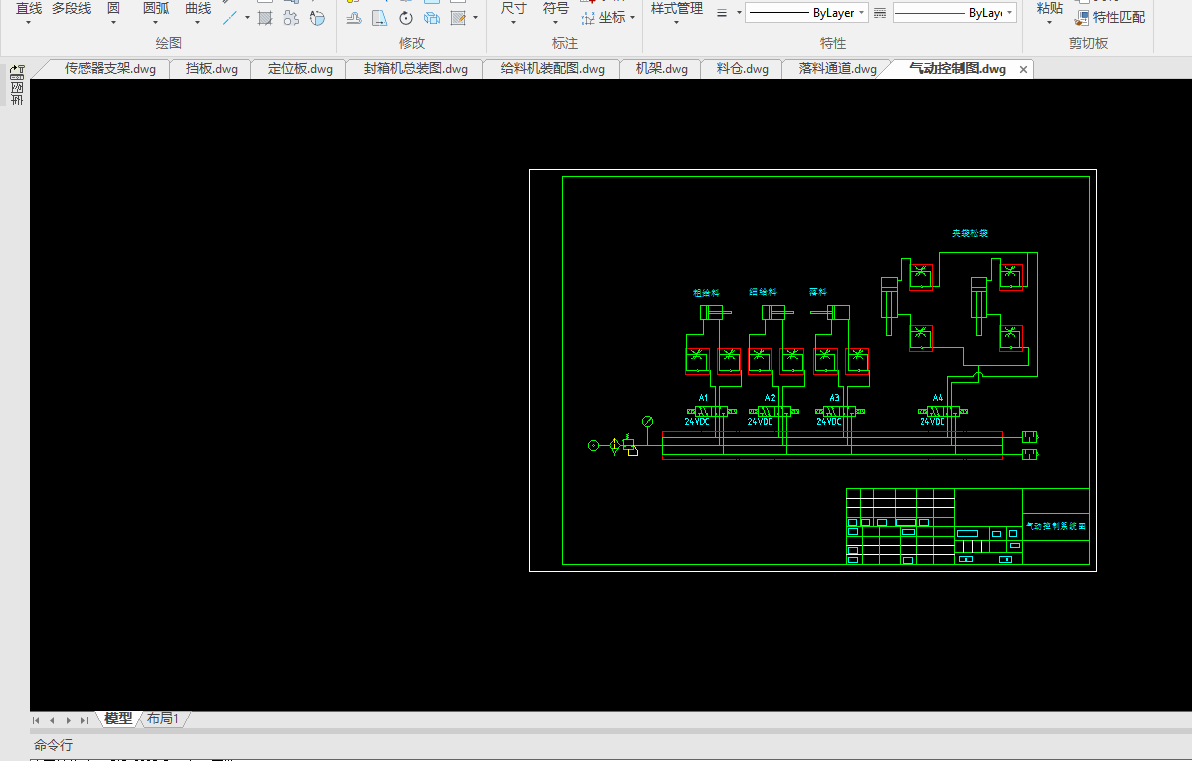

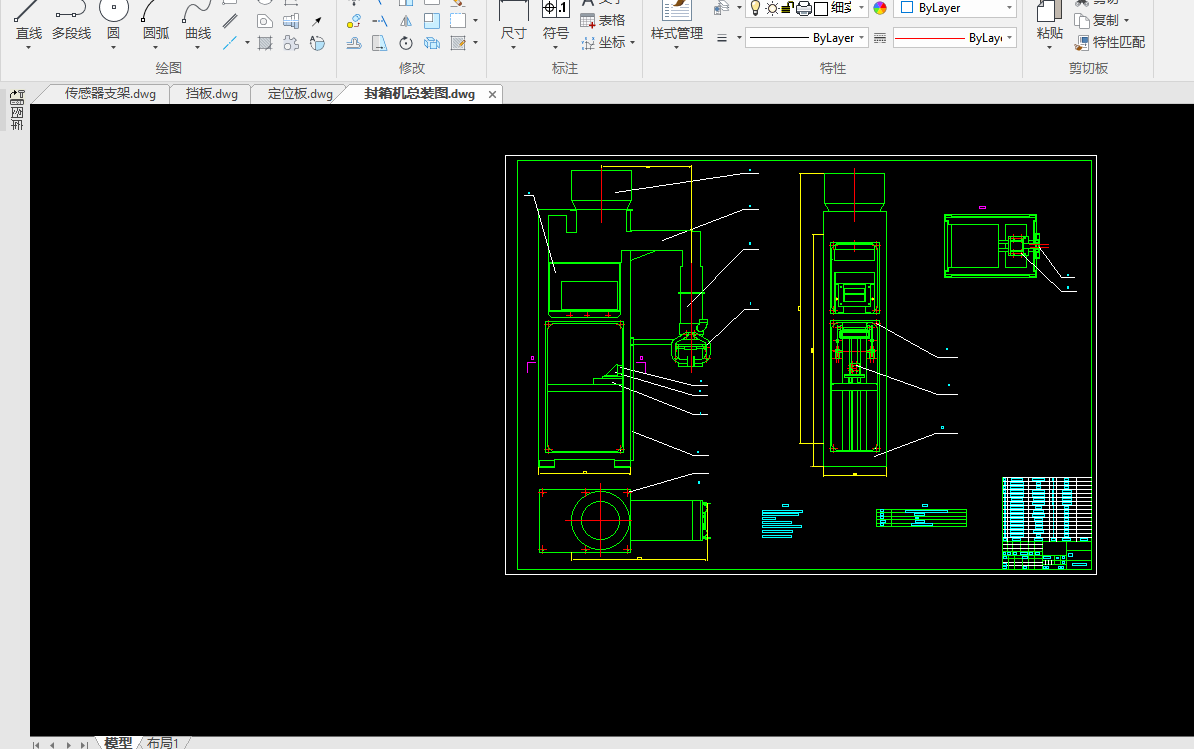

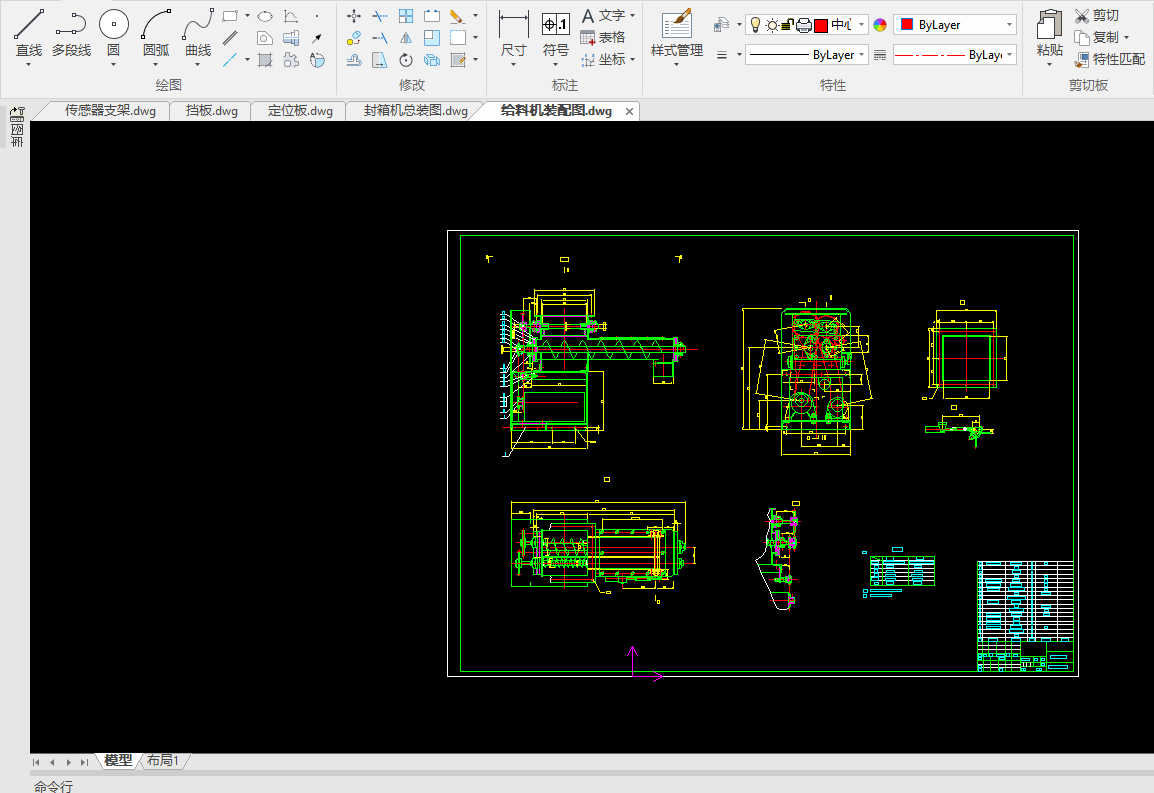

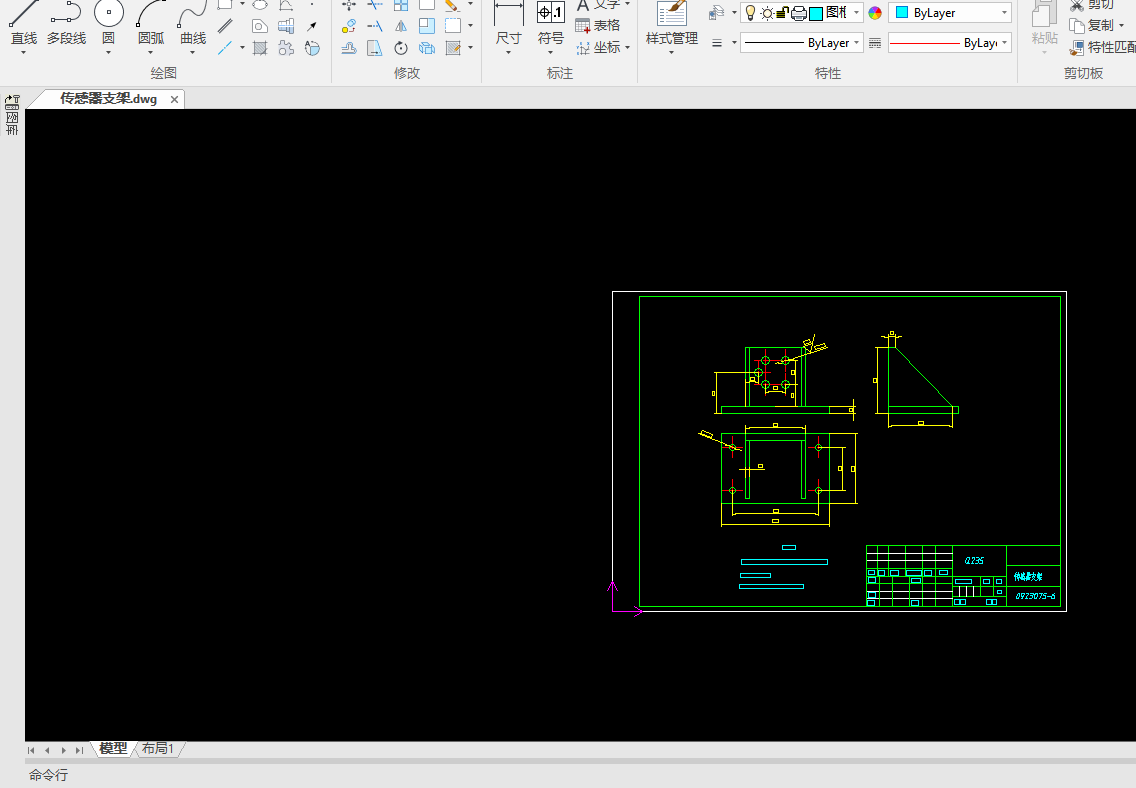

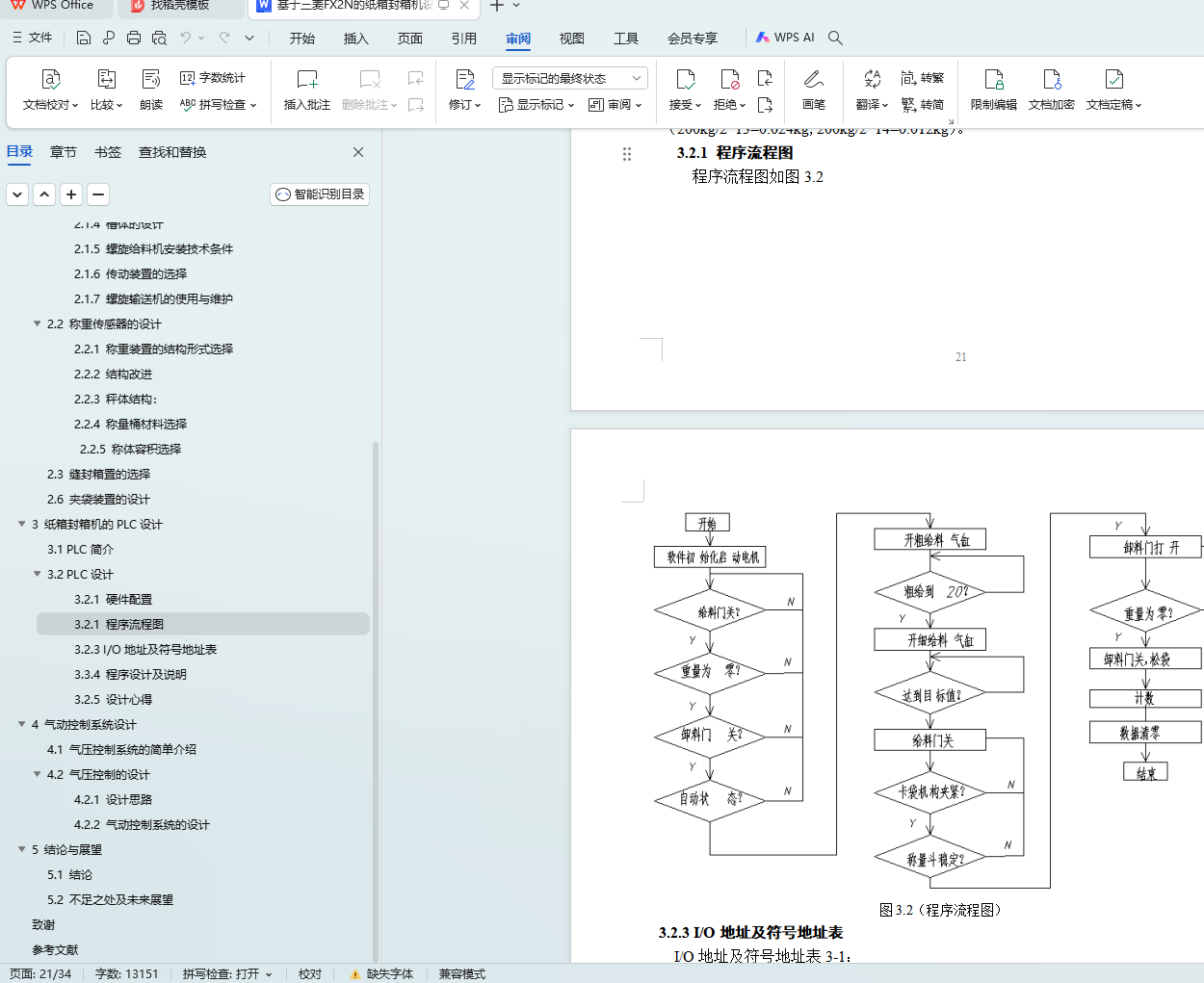

本文介绍了基于三菱FX2N的纸箱自动定量封箱机的设计。该封箱机采用净重式电子秤,通过双螺旋给料机、电子称、下料斗、袋夹、输送机、缝包系统以及包含PLC、称重控制仪、重量传感器等的智能电控系统,实现了给料、称量、夹袋、放料等工序的自动化。该系统适用于纯碱、面粉、淀粉、饲料等粉状物料的自动定量、计量与封箱,可广泛应用于食品、化工、轻工、建材等行业。该设计不仅提高了生产效率,降低了人工成本,而且提高了产品计量的准确性,对于提升相关行业的自动化水平和产品质量具有重要意义。

关键词: 三菱FX2N;纸箱封箱机;净重式电子秤;双螺旋给料机;自动定量

Abstract

This paper describes the design of automatic quantitative packing machine based on Mitsubishi FX 2 N. The box sealing machine adopts the net weight electronic scale, through the double spiral feeder, electronic weighing, hopper, bag clip, conveyor, sewing system, intelligent electronic control system, and the inclusion of PLC, weighing controller, weight sensor and so on. The system is suitable for the automatic quantification, measurement and sealing of soda ash materials such as soda, flour, starch and feed, and can be widely used in food, chemical industry, light industry, building materials and other industries. The design not only improves the production efficiency, reduces the labor cost, but also improves the accuracy of product measurement, which is of great significance to improving the level of automation and product quality of related industries.

Key words: Mitsubishi FX 2 N; carton sealing machine; net weight electronic scale; double spiral feeder; automatic quantification