基于西门子PLC的除尘系统电气控制箱系统 说明书(论文)+任务书+外文翻译及原文+cad图纸

基于西门子PLC的除尘系统电气控制箱系统

摘 要

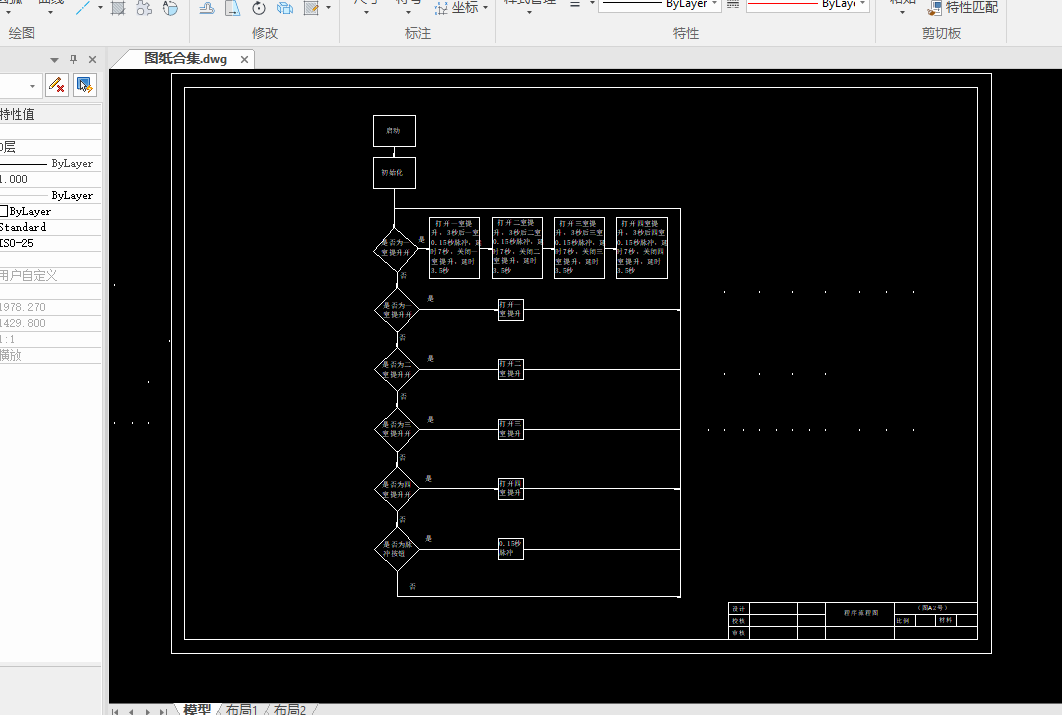

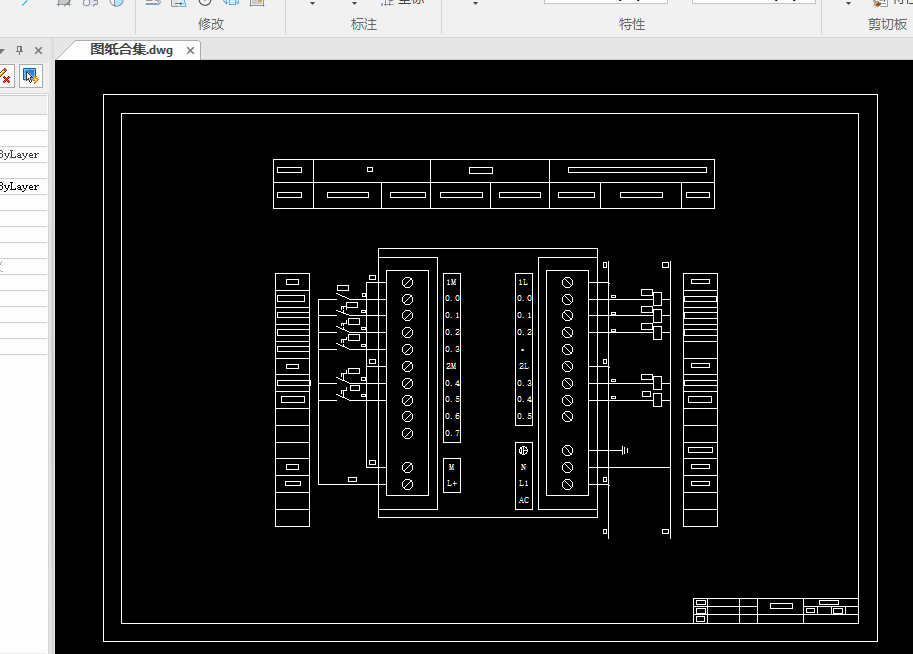

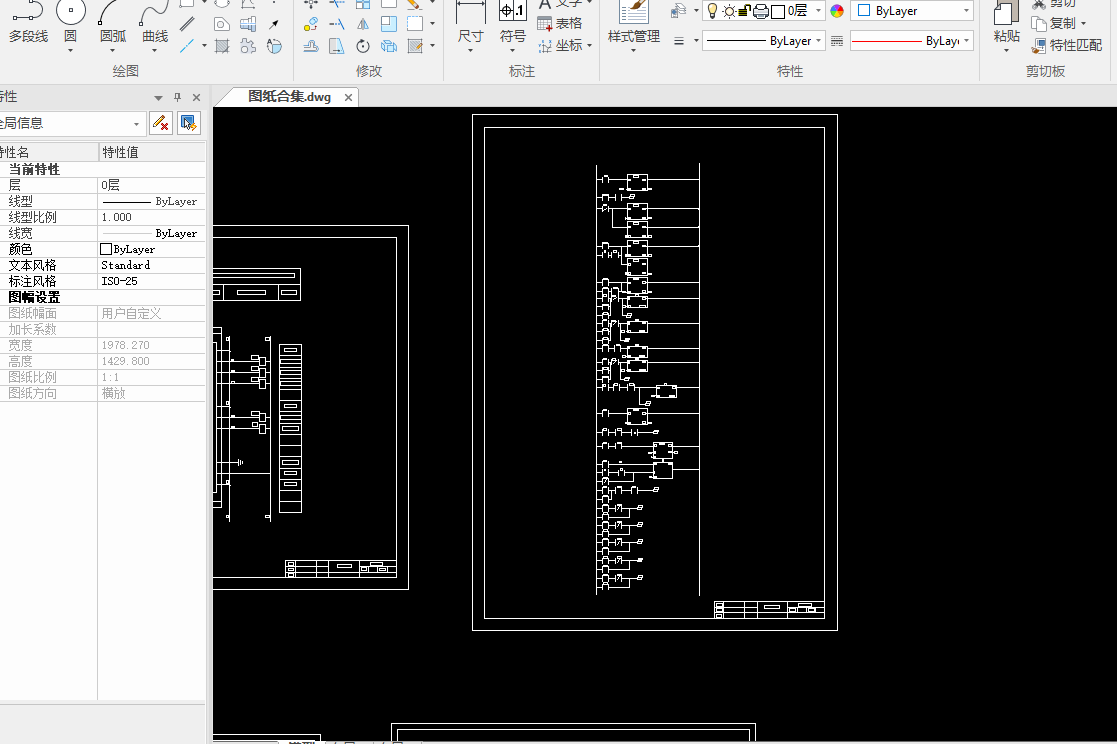

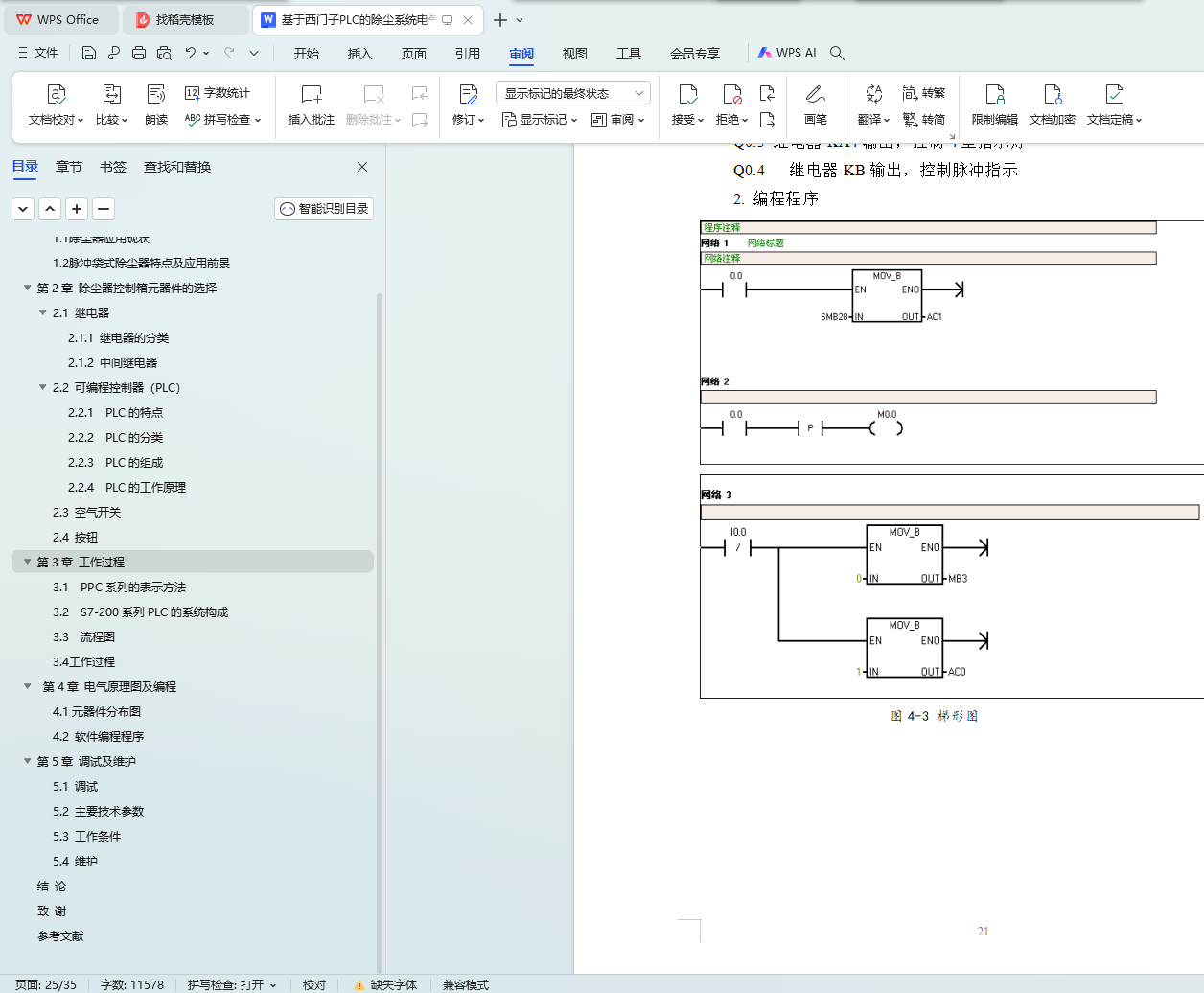

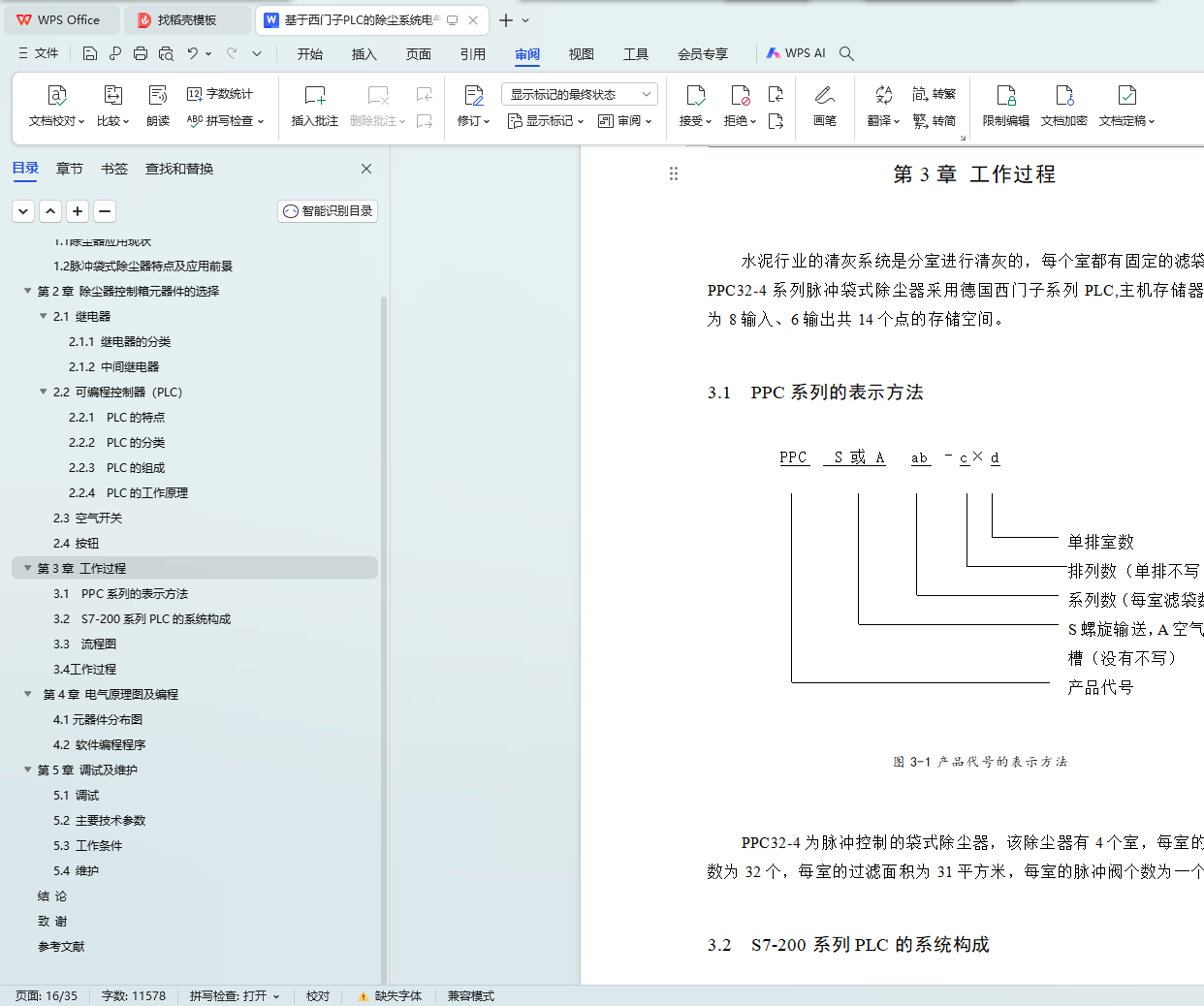

PPC32-4是应用在水泥行业的脉冲袋式除尘系统的控制箱,它是清灰系统的电气控制部分。操作时分为手动、自动和远控三种操作方法。每种操作都是通过脉冲上升沿的到来控制各个室的清灰。自动操作按照编程程序设定的时间对4个室进行清灰,循环进行,且各个室的清灰时间相同。当使用手动操作时,可以根据每个室灰的浓度的不同来控制清灰的时间。远控即自动操作过程。本设计的基本元器件有继电器、可编程控制器(PLC)、空气开关、指示灯等构成电路图,借用Auto CAD辅助工具画出其电气接线图。并借助于STEP 7-Micro WIN编程软件编制T形图语言,来完成电气控制箱的设计。通过本文的研究可以使除尘设备在安全可靠的系统中运行,保证其持续可靠的清灰。

关键词:继电器,可编程控制器,除尘系统,电器控制

The Studying of Electric Control Cabinet of Dust Removal System on The Basis of PLC

ABSTRACT

PPC32-4 control box pulse bag dust collector cleaning system is part of the electrical control. Manual automatic and remote control of three methods of operation. Each operation is controlled by the arrival of the various pulse rising edge of the room cleaning. Automatic programming process according to the time set on the four rooms cleaning, cycles, and cleaning each room the same time. When using the manual operation, each room according to the different gray levels to control the cleaning time. Remote control or automatic operation. The design of the basic components are relays, PLC, air switches, Indicator lights, constitute a circuit, auxiliary tools to use Auto CAD to draw its electrical wiring diagram. And the help of STEP 7-Micro WIN Software for T-chart programming language to accomplish the design of electrical control box. Through this research can make dust removal equipment in a safe and reliable system operation, to ensure its continued reliable cleaning.

KEY WORDS: Relay ,Programmable controller ,Cleaning system ,Electrical control

目 录