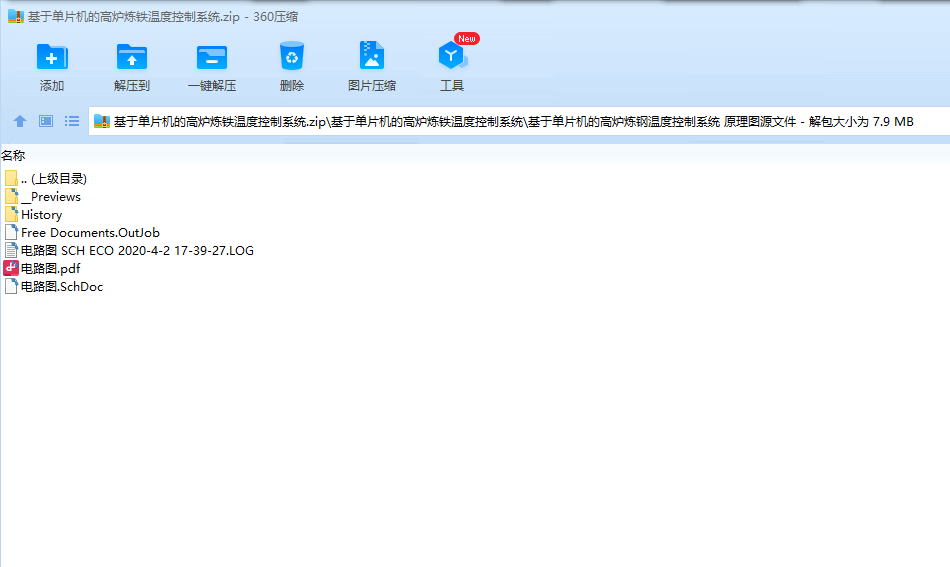

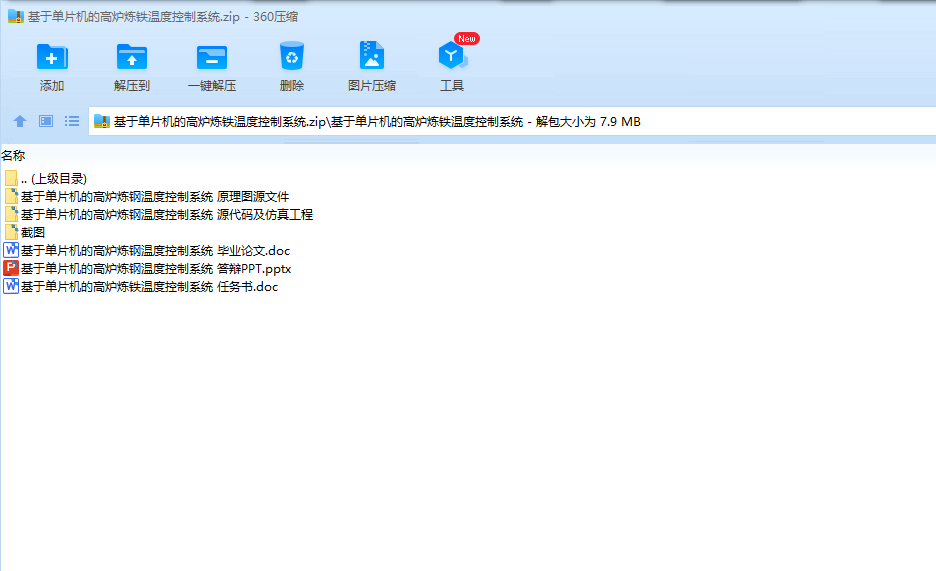

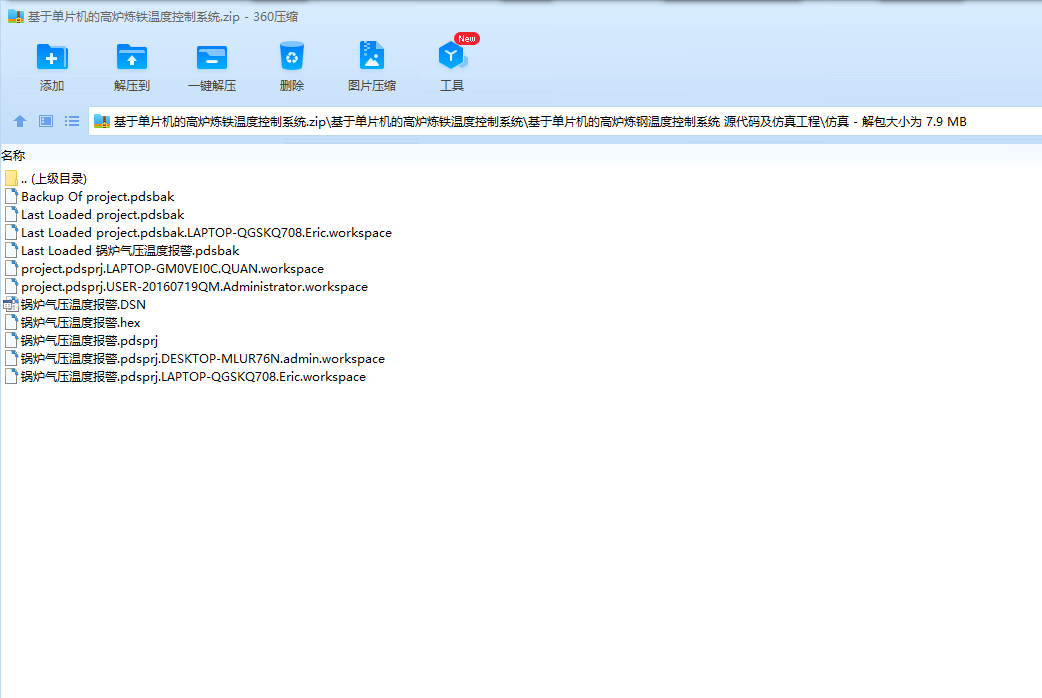

基于单片机的高炉炼钢温度控制系统 毕业论文+任务书+答辩PPT+外文翻译及原文+原理图及源文件+ 源代码及仿真工程文件

摘 要

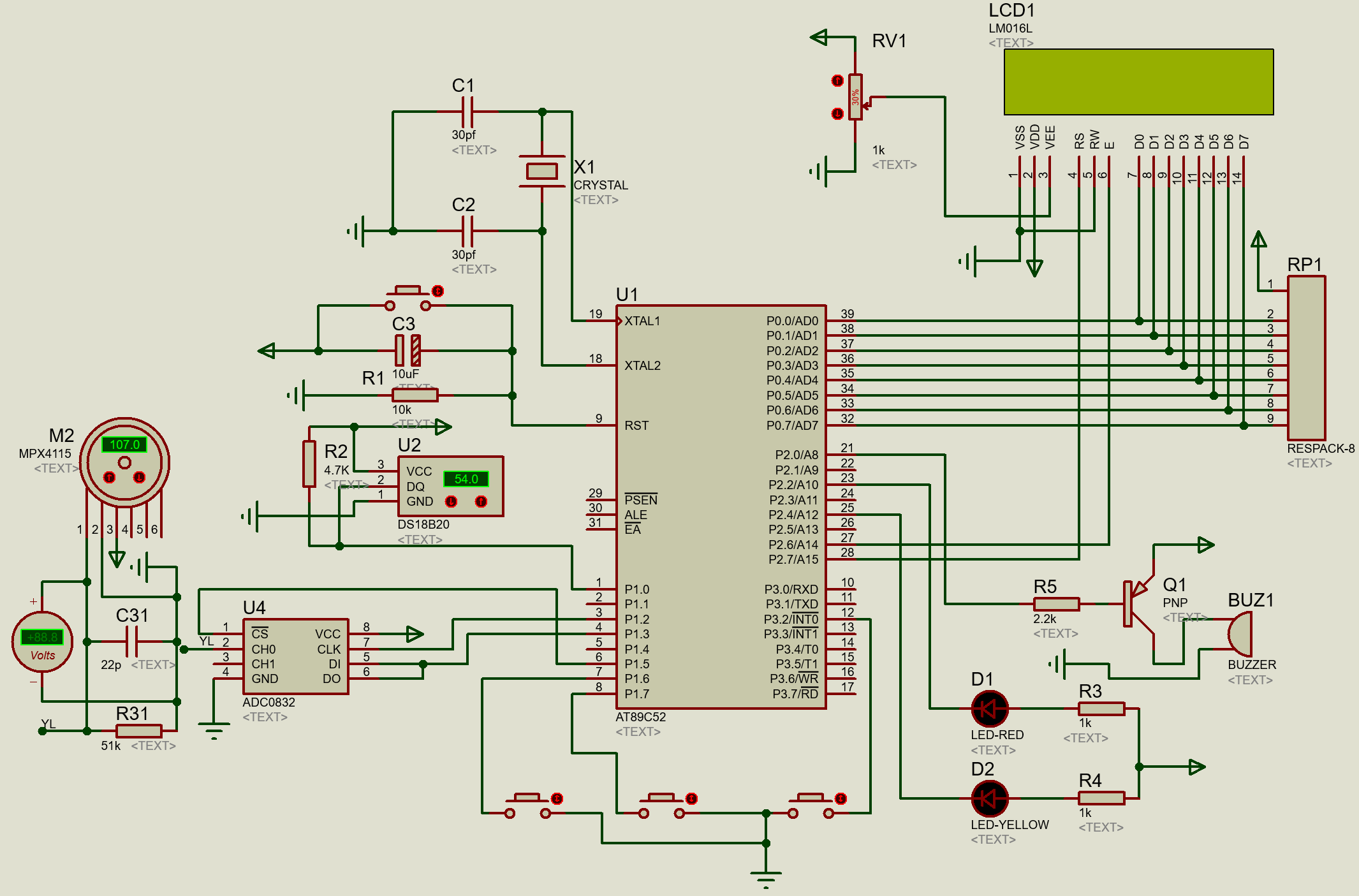

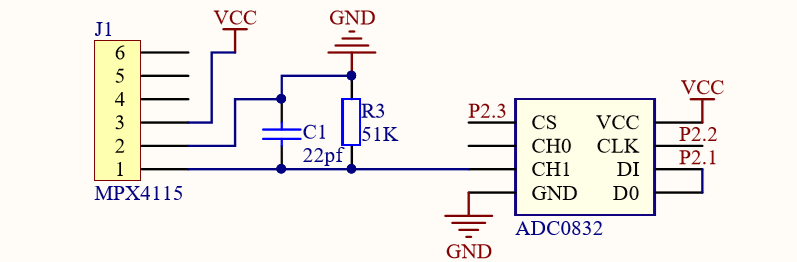

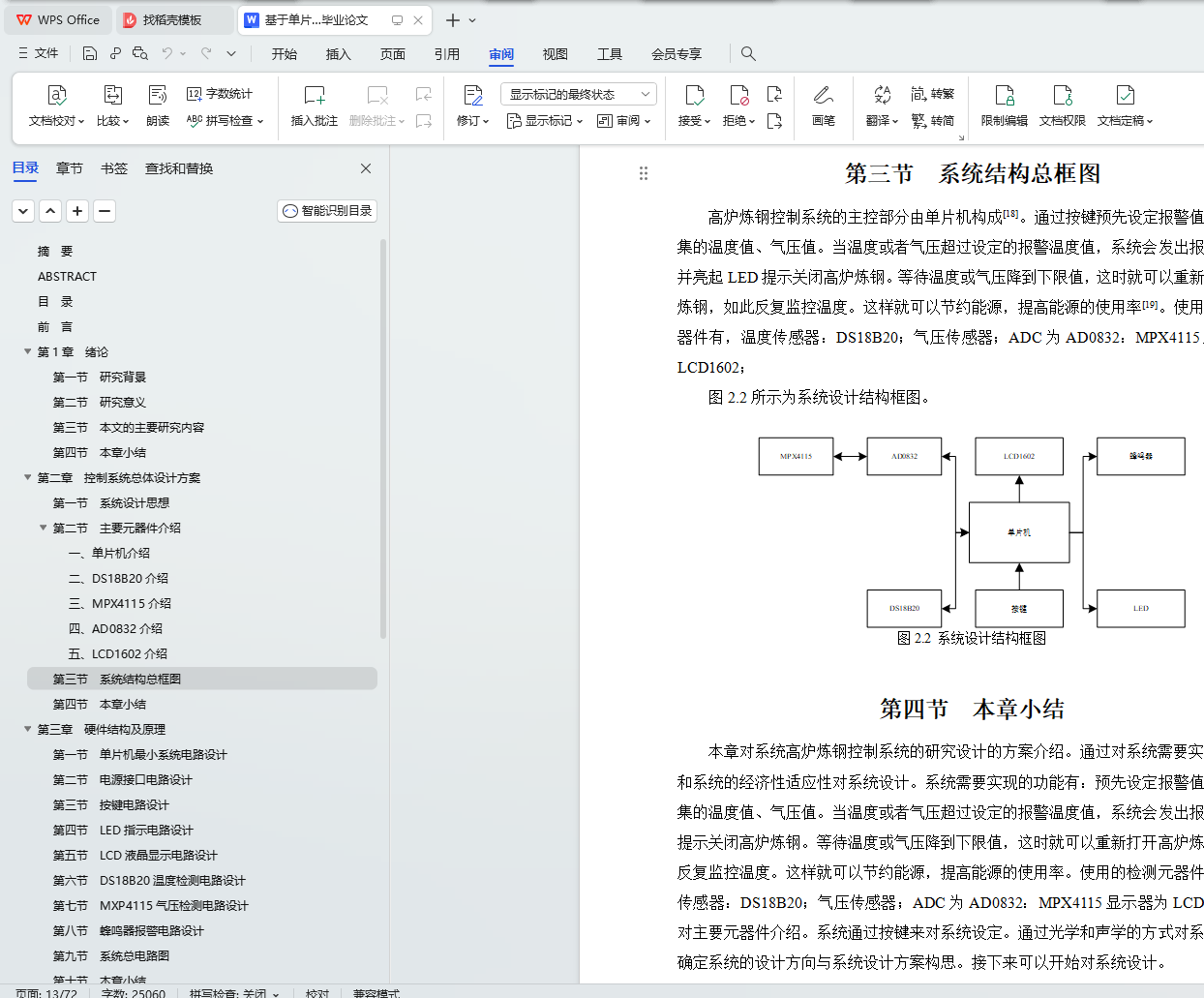

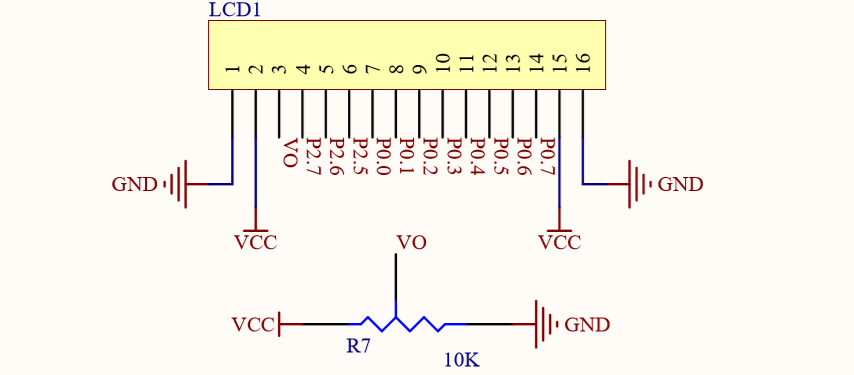

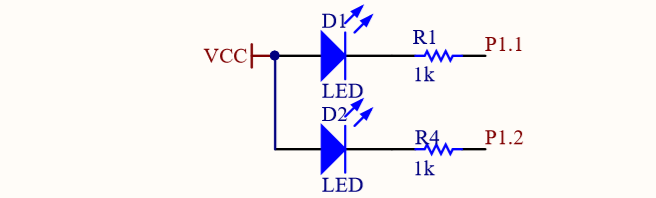

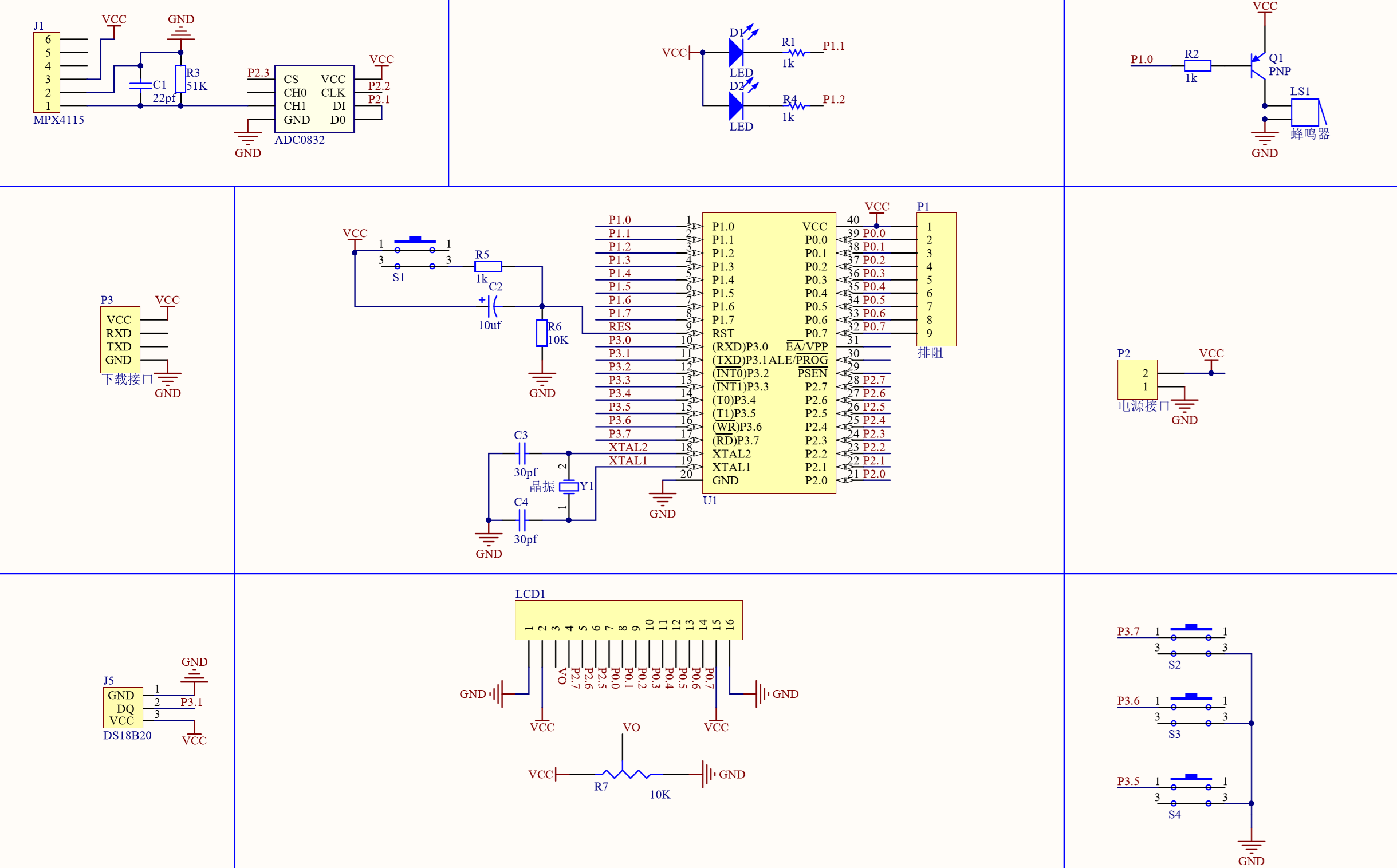

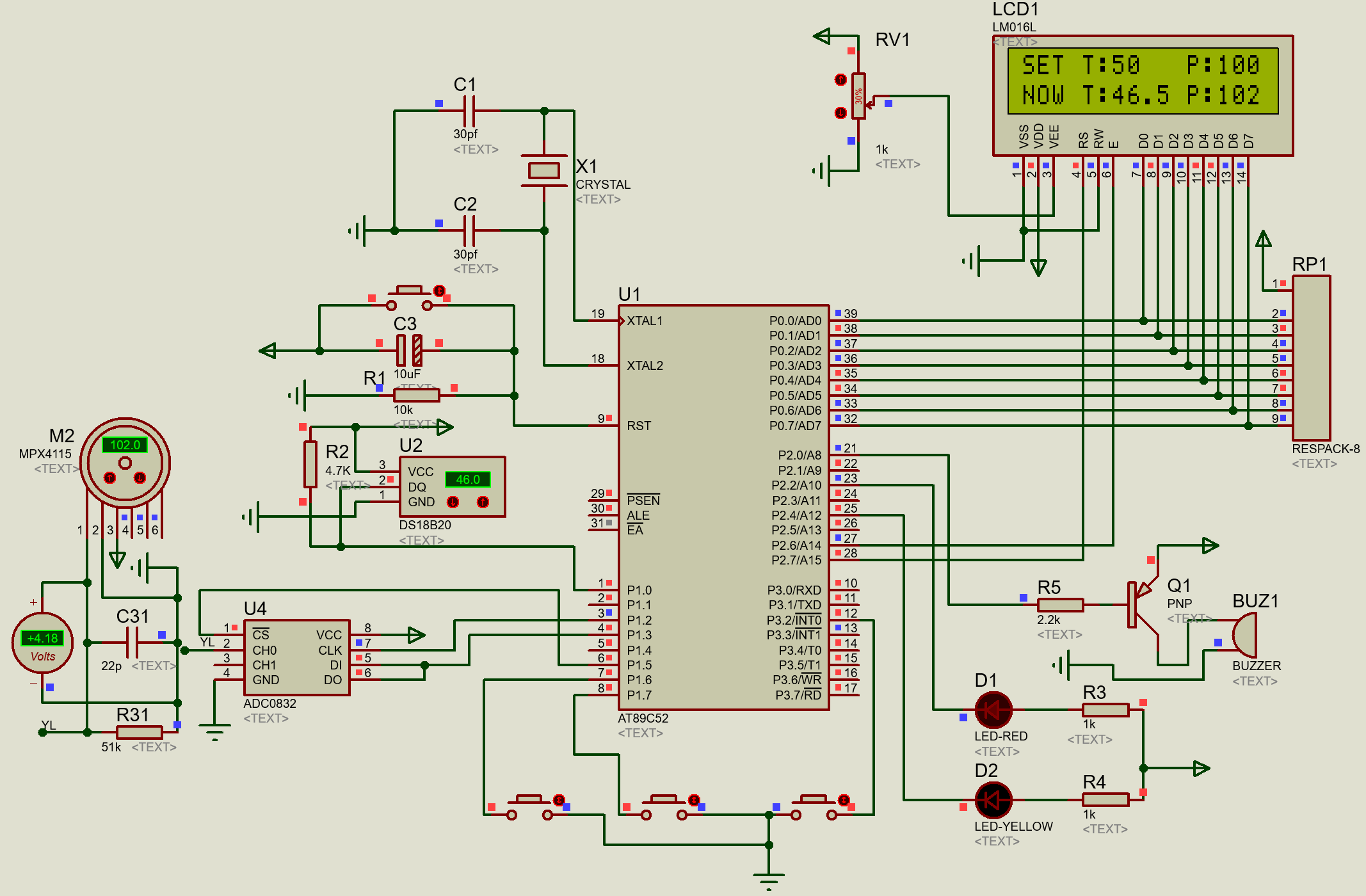

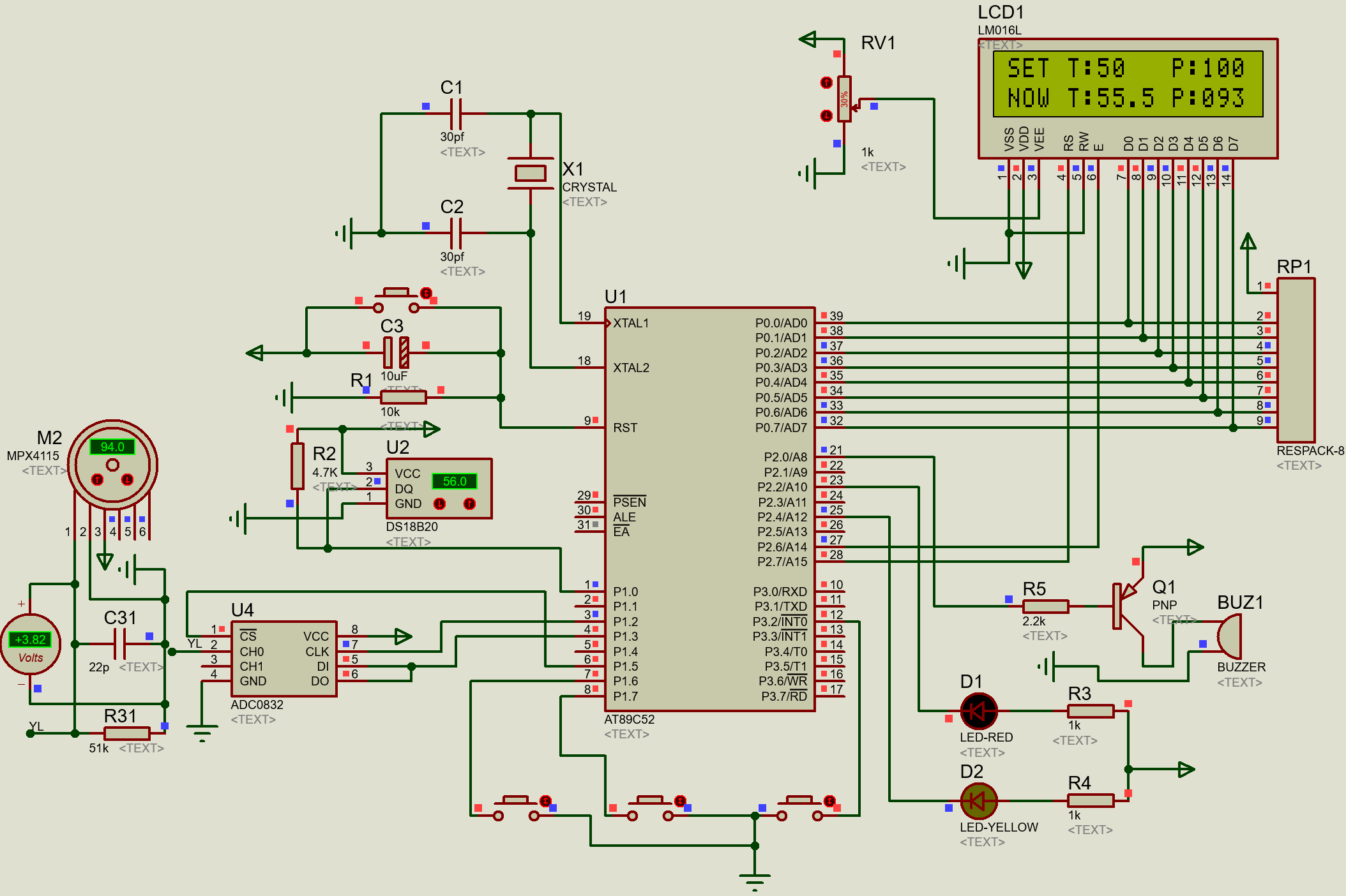

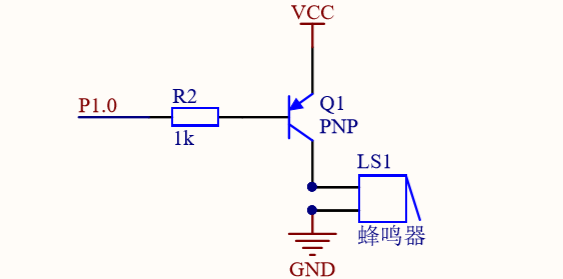

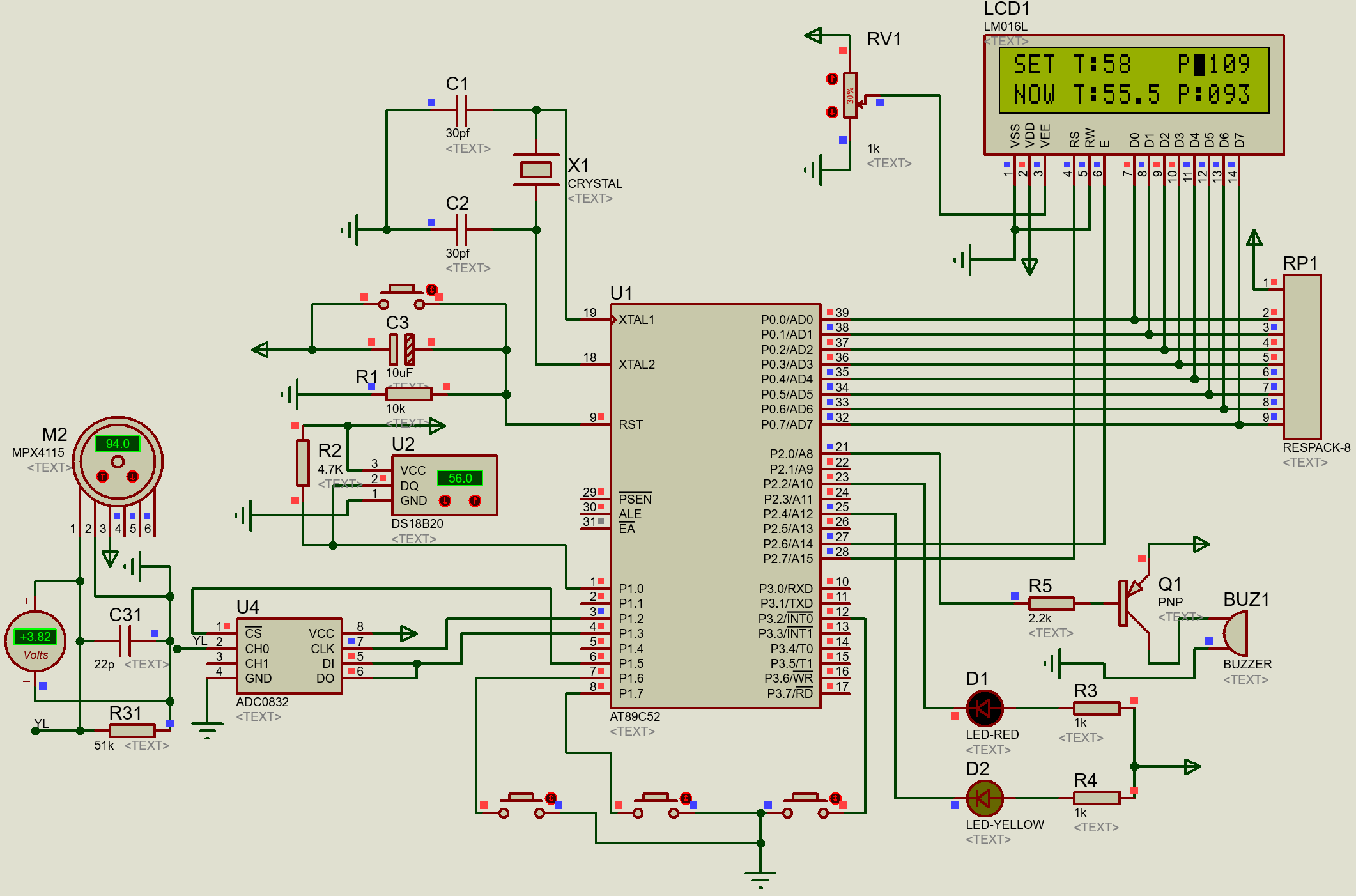

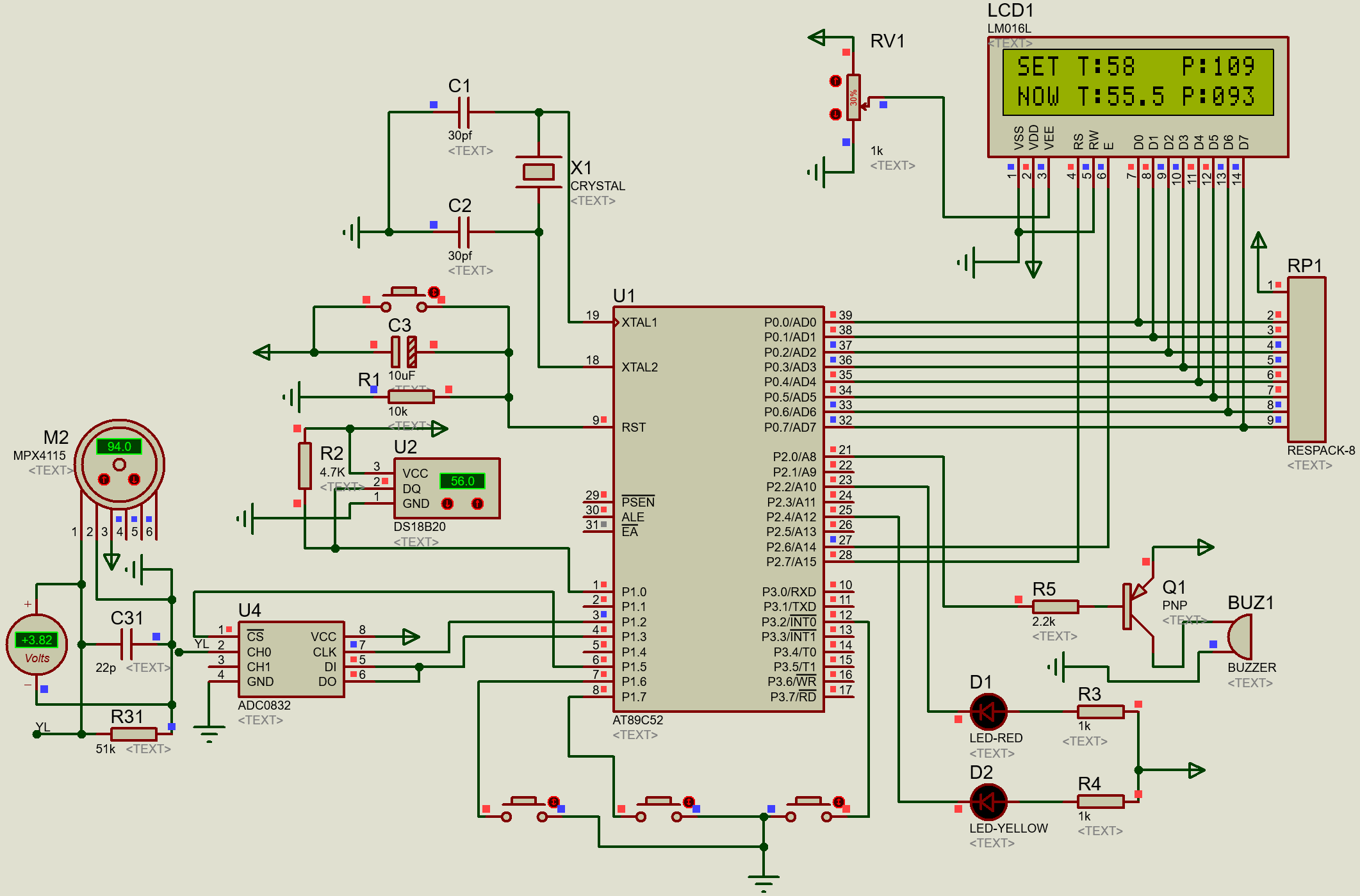

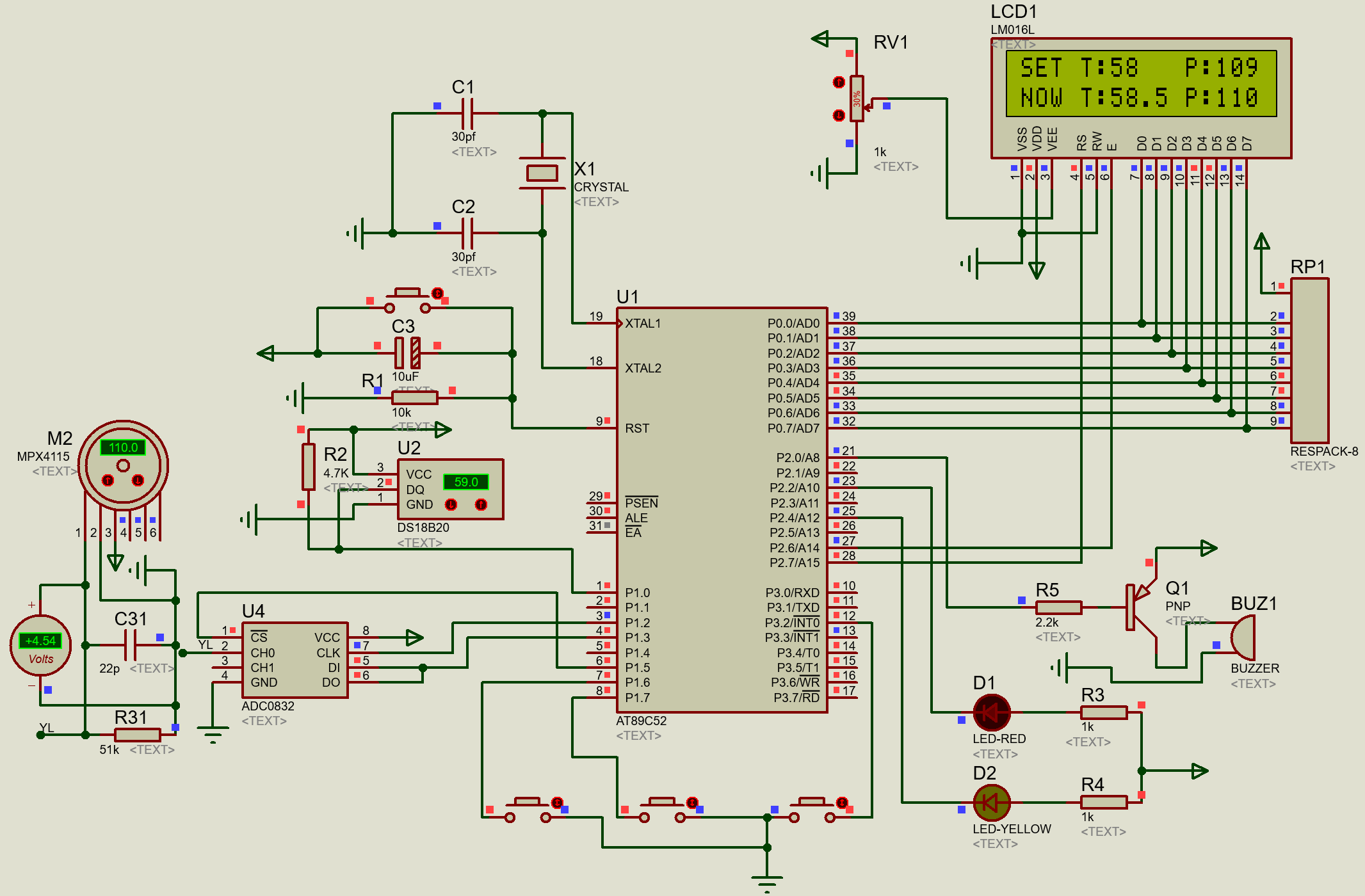

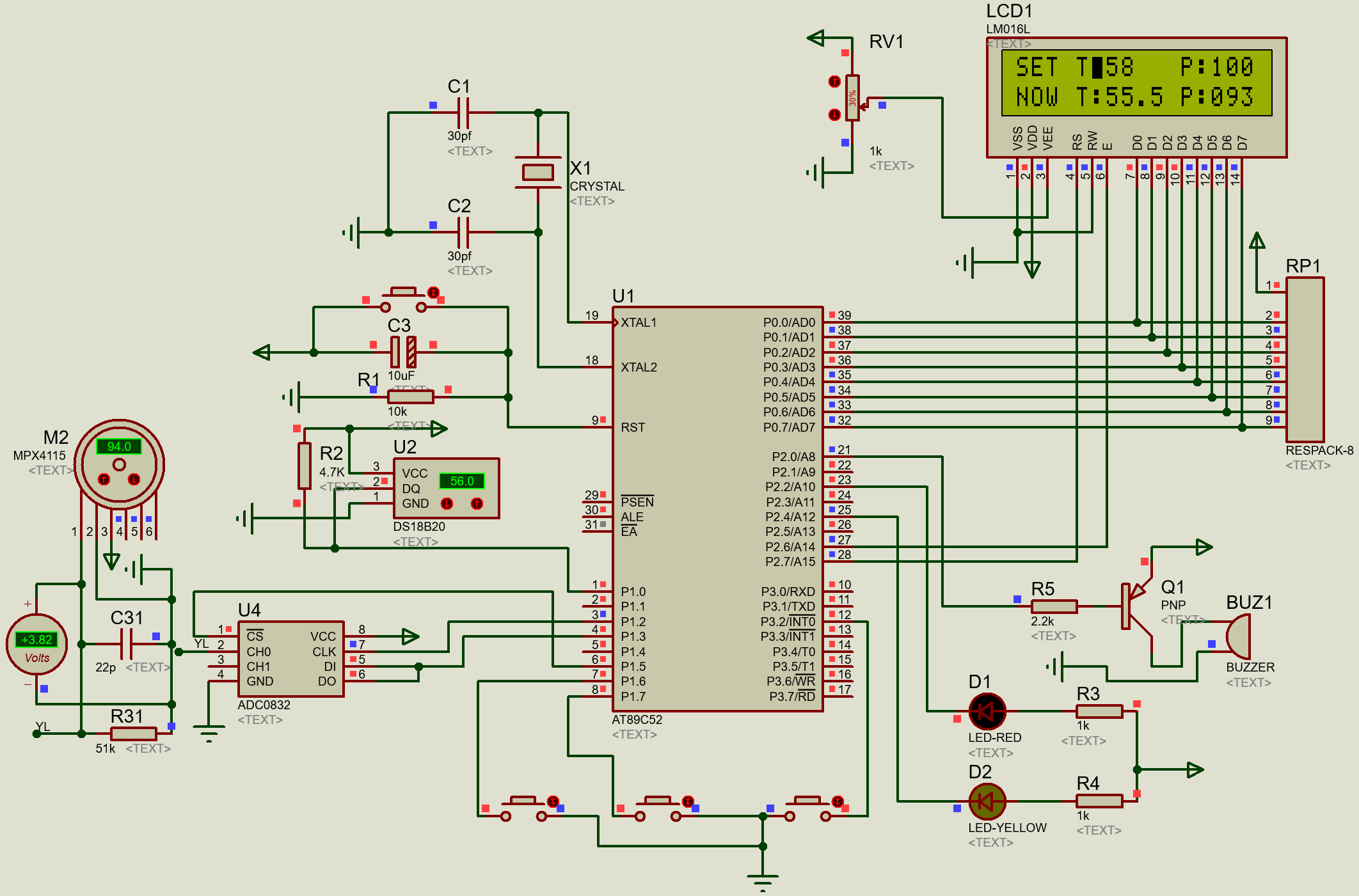

本文选题为基于单片机的高炉炼钢温度控制系统研究,选用MPX4115传感器、ADC0832模数转换器和DS18B20温度传感器等核心元器件,采用STC89C52单片机和LCD1602液晶显示器构建硬件电路,通过编写相应的软件程序,实现了炉温的精确控制。本文详细介绍了系统的设计思想、硬件电路搭建和软件编写过程,并通过PROTEUS仿真进行实验验证。

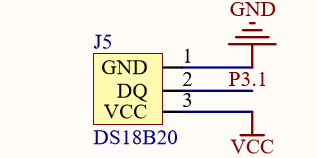

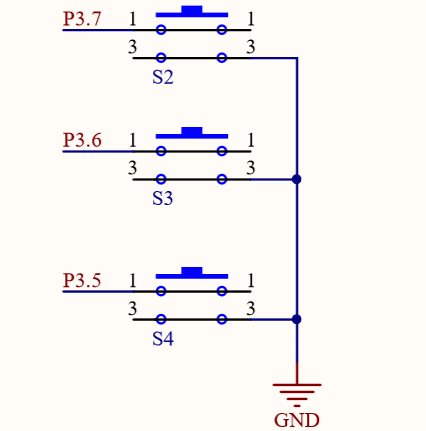

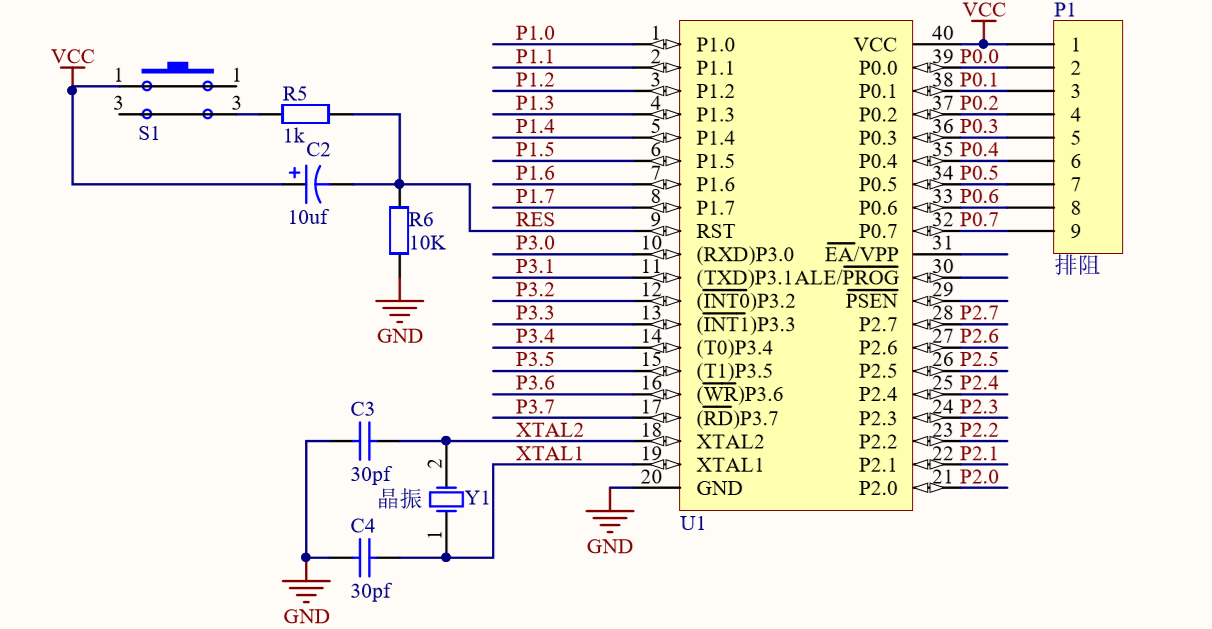

在硬件电路搭建方面,本文针对系统所需的传感器类型和电气特性,设计了一套完整的电路方案,包括传感器接口、ADC模块、显示模块等核心部件,对每个元器件的使用方法和工作原理进行了详细讲解。

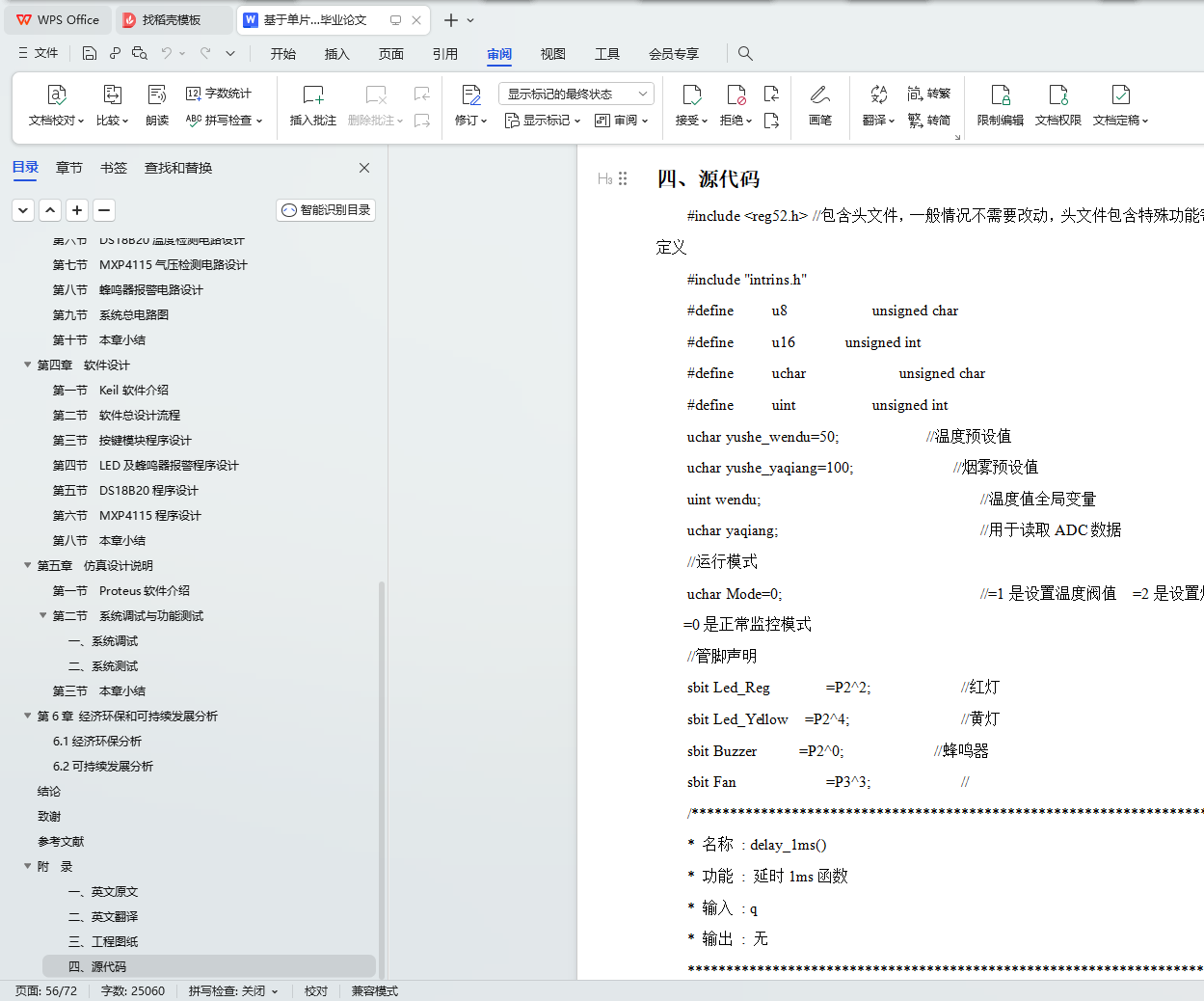

在软件编写方面,本文利用Keil μVision IDE进行程序开发,通过汇编和C语言混合编程的方式,完成了炉温采集、控制和显示等主要功能,实现了对高炉炼钢温度的稳定控制和实时监测。

最后,通过PROTEUS仿真进行实验验证,本文得出了系统的精密度、稳定性和实用性等方面的评价,证明了本设计方案的可行性和优越性,为实现钢铁生产过程的智能化控制提供了可靠的技术支持。

关键词:高炉炼钢;温度控制;压强;报警;单片机

ABSTRACT

The topic of this paper is the blast furnace temperature control system, select MPX4115 sensor, ADC0832 analog to digital converter and DS18B20 temperature sensor and other core components, using STC89C52 single chip unit and LCD1602 liquid crystal display to build hardware circuit, realize the precise temperature control through the corresponding software program.

This paper introduces the design idea, hardware circuit construction and software writing process, and verifies it through PROTEUS simulation. In terms of hardware circuit construction, this paper designs a complete set of circuit scheme according to the sensor types and electrical characteristics required by the system, including sensor interface, ADC module, display module and other core components, and explains the use method and working principle of each component in detail.

In terms of software writing, this paper uses Keil μVision IDE to carry out program development, through the mixed programming of assembly and C language, completes the main functions of furnace temperature collection, control and display, and realizes the stable control and real-time monitoring of blast furnace steelmaking temperature.

Finally, through PROTEUS simulation, this paper obtains the evaluation of the precision, stability and practicability of the system, which proves the feasibility and superiority of the design scheme, and provides reliable technical support for the intelligent control of steel production process.

Key words: blast furnace steelmaking; temperature control; pressure; alarm; SU

目 录