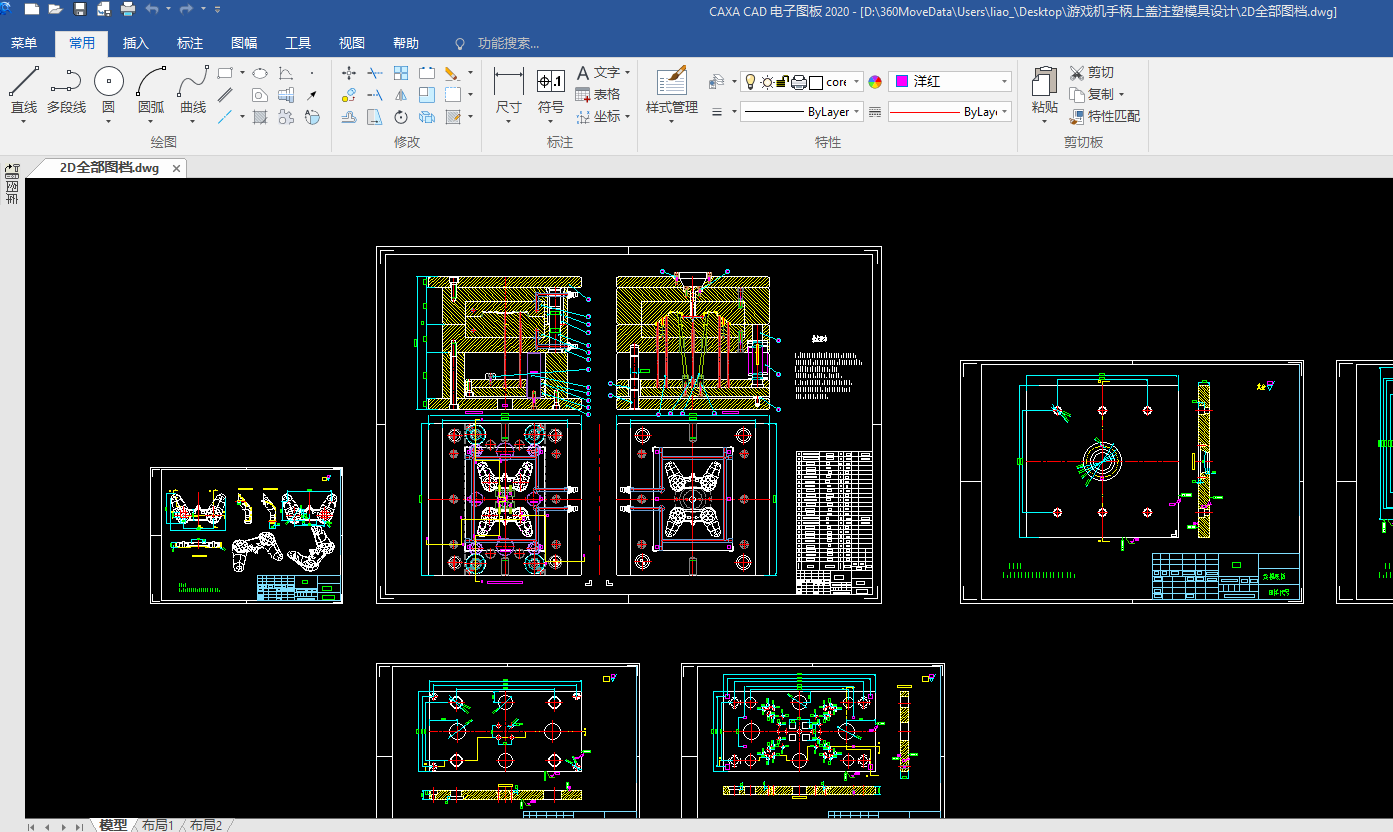

游戏机手柄上盖注塑模具设计与优化 说明书(论文)+CAD图纸+proe三维图+模流分析文件

摘 要

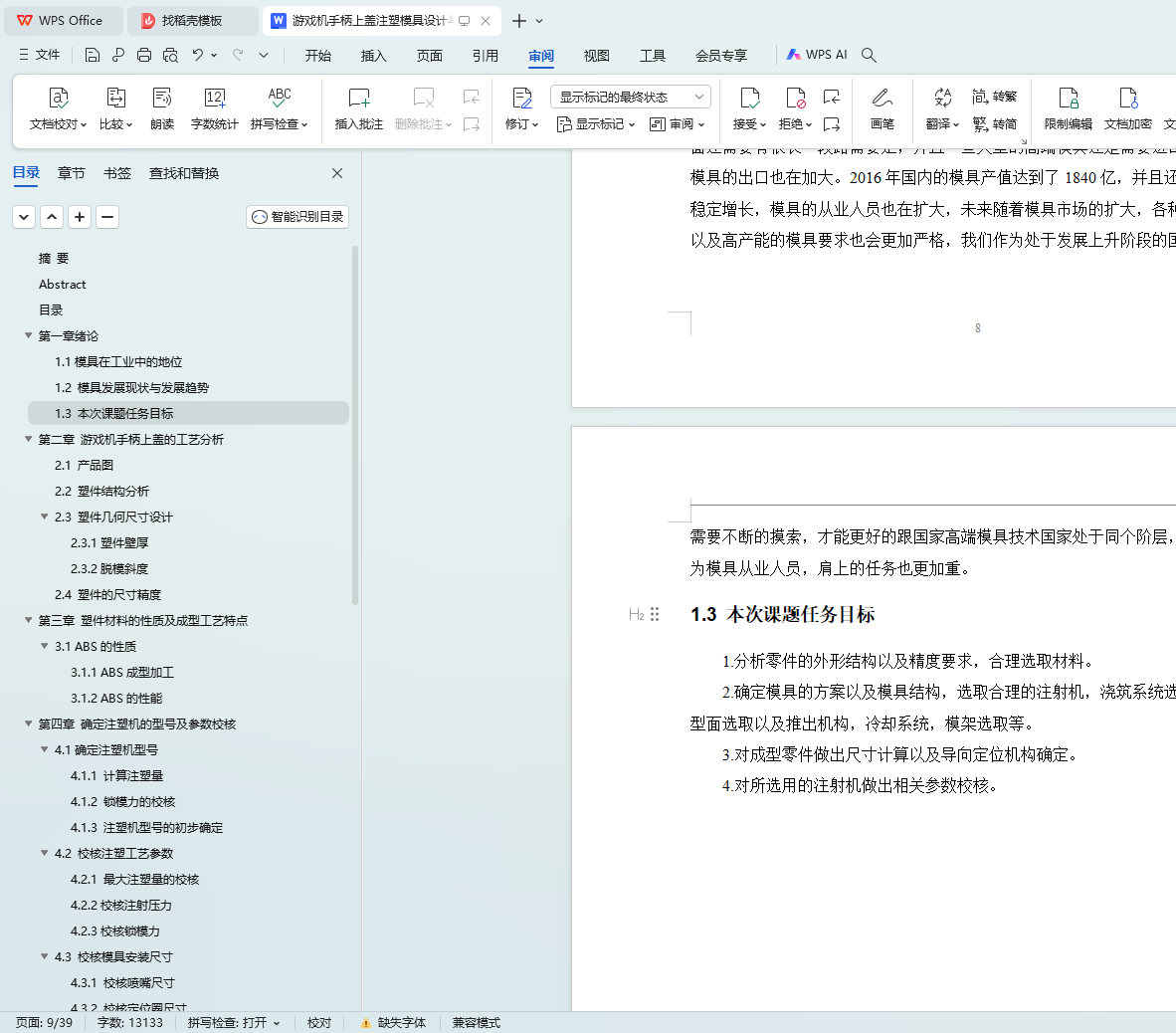

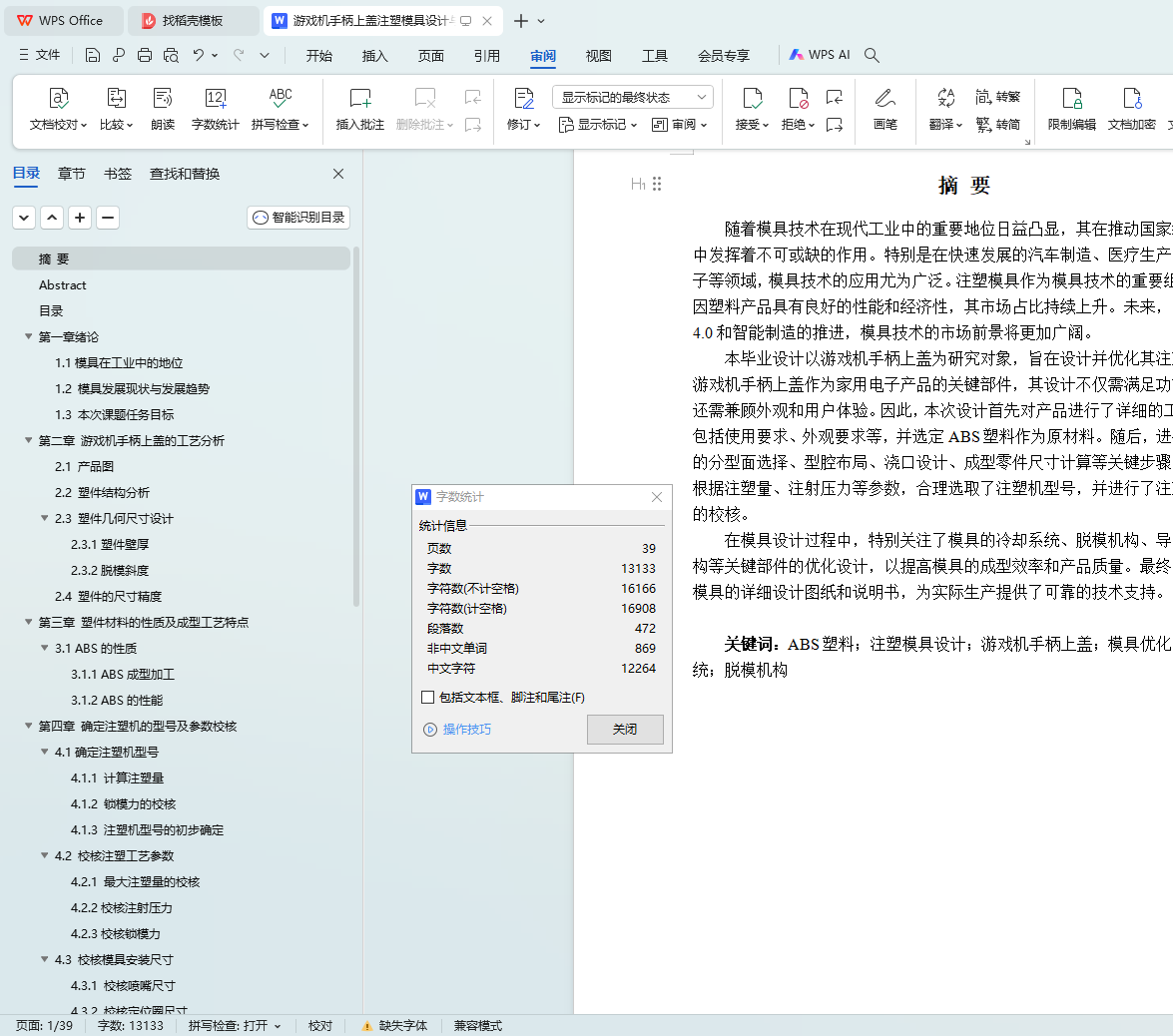

随着模具技术在现代工业中的重要地位日益凸显,其在推动国家经济发展中发挥着不可或缺的作用。特别是在快速发展的汽车制造、医疗生产、电器电子等领域,模具技术的应用尤为广泛。注塑模具作为模具技术的重要组成部分,因塑料产品具有良好的性能和经济性,其市场占比持续上升。未来,随着工业4.0和智能制造的推进,模具技术的市场前景将更加广阔。

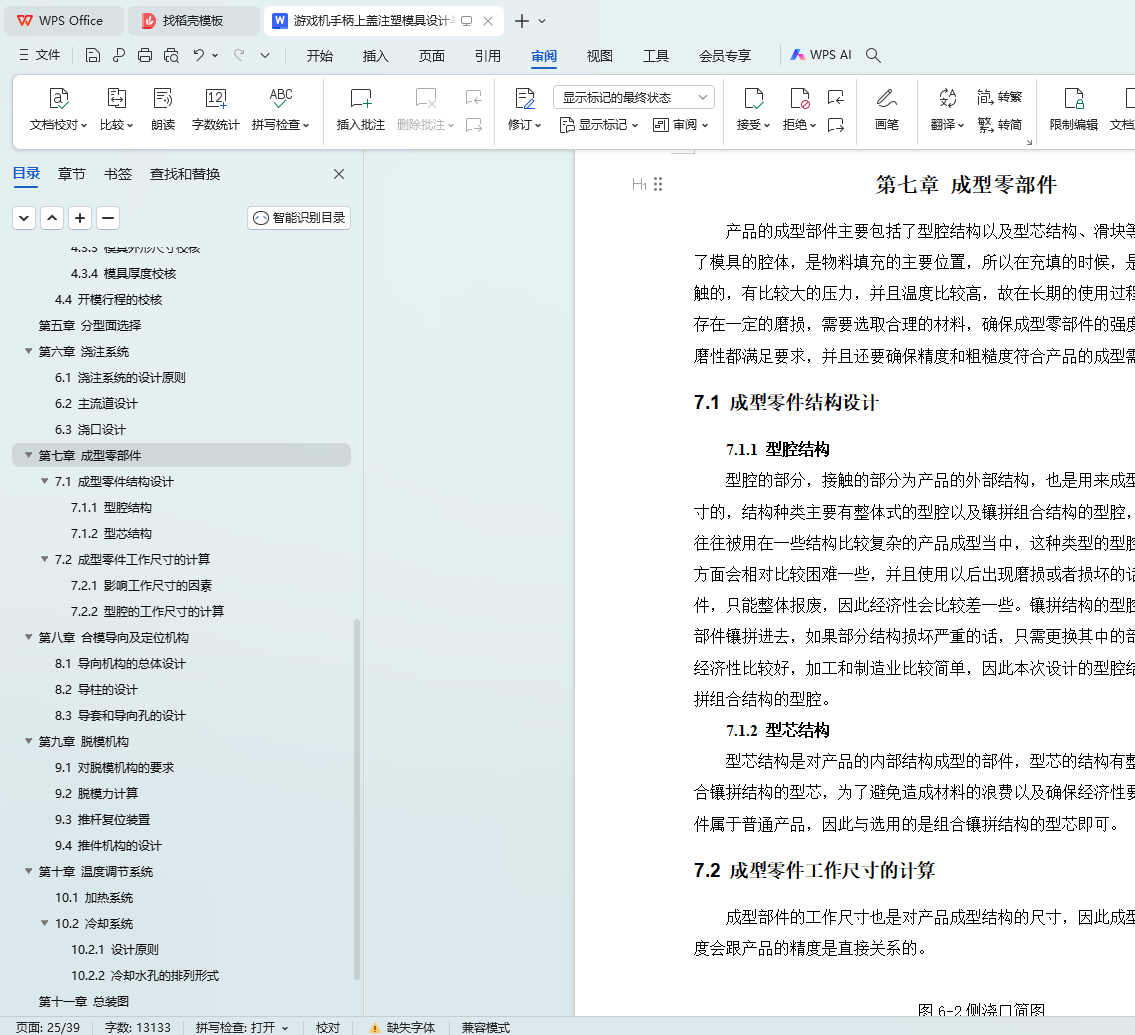

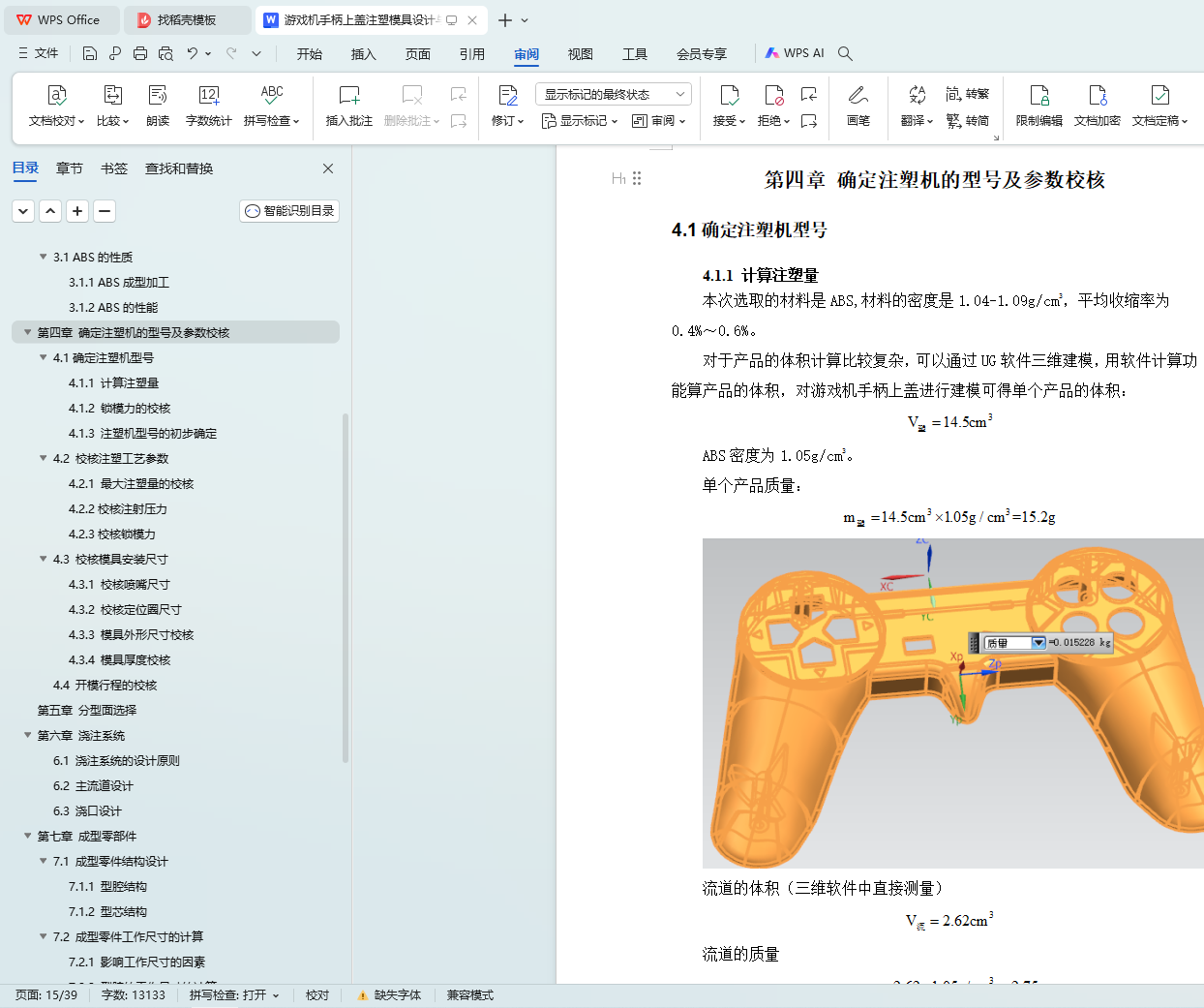

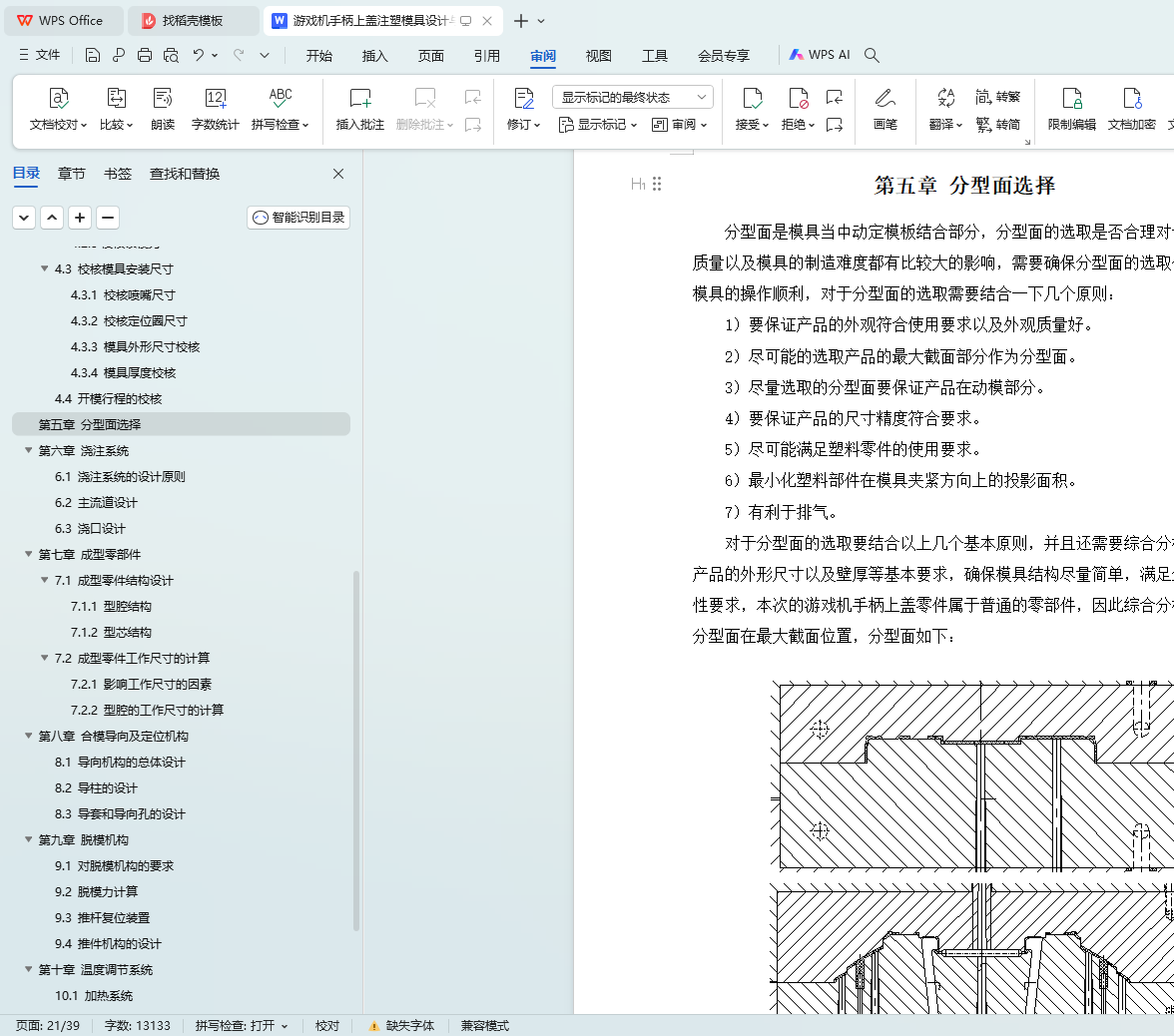

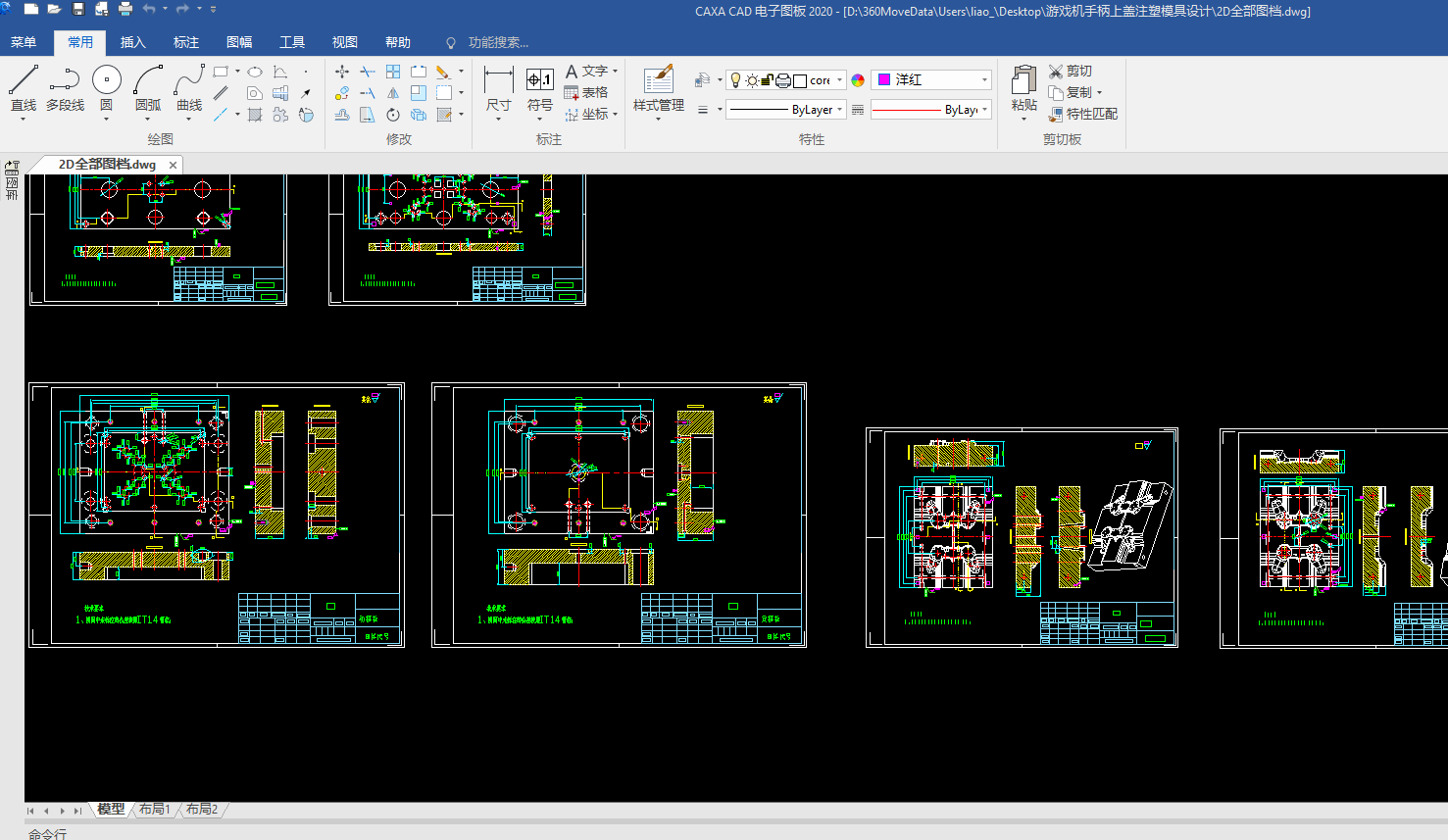

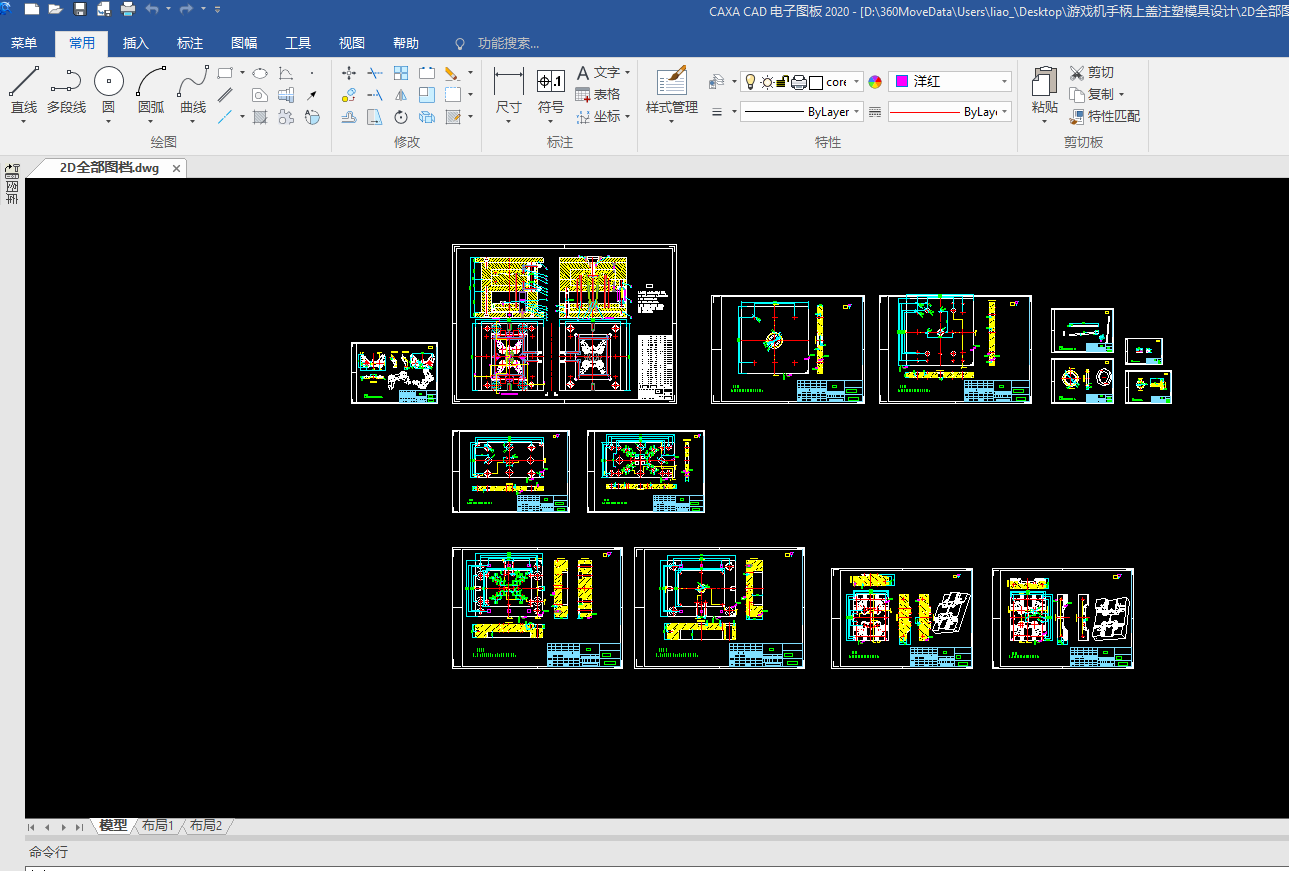

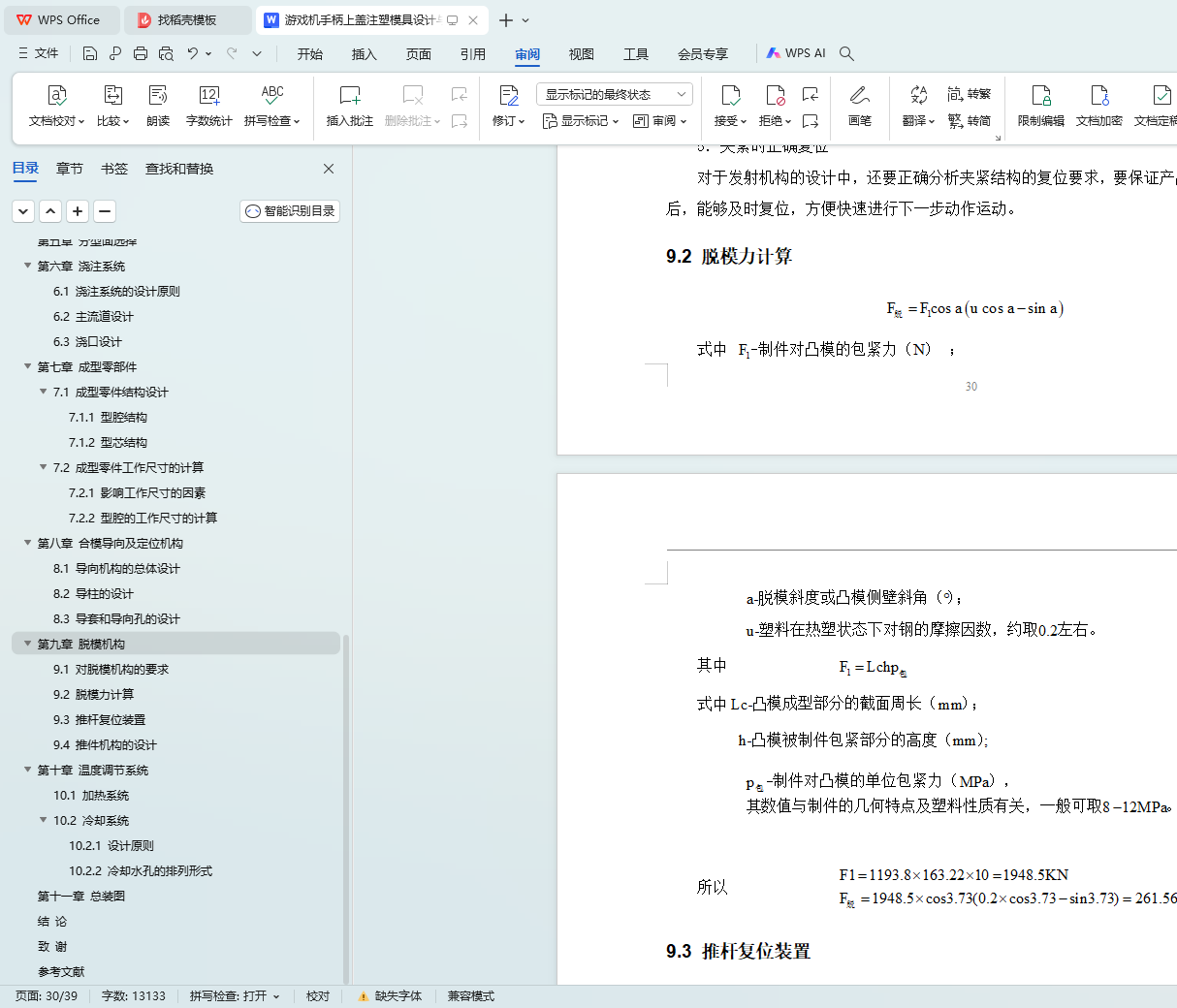

本毕业设计以游戏机手柄上盖为研究对象,旨在设计并优化其注塑模具。游戏机手柄上盖作为家用电子产品的关键部件,其设计不仅需满足功能需求,还需兼顾外观和用户体验。因此,本次设计首先对产品进行了详细的工艺分析,包括使用要求、外观要求等,并选定ABS塑料作为原材料。随后,进行了模具的分型面选择、型腔布局、浇口设计、成型零件尺寸计算等关键步骤。同时,根据注塑量、注射压力等参数,合理选取了注塑机型号,并进行了注塑机参数的校核。

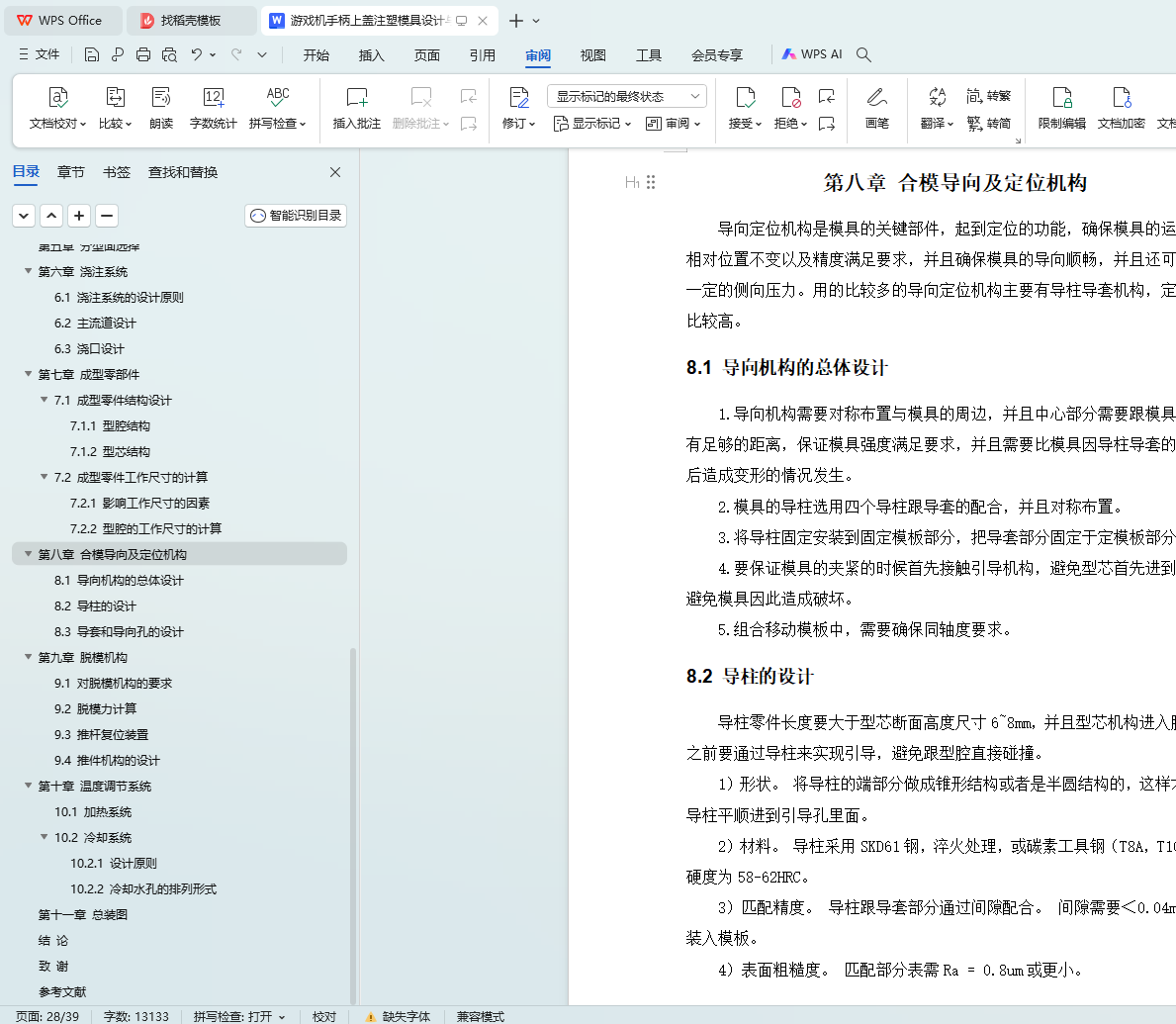

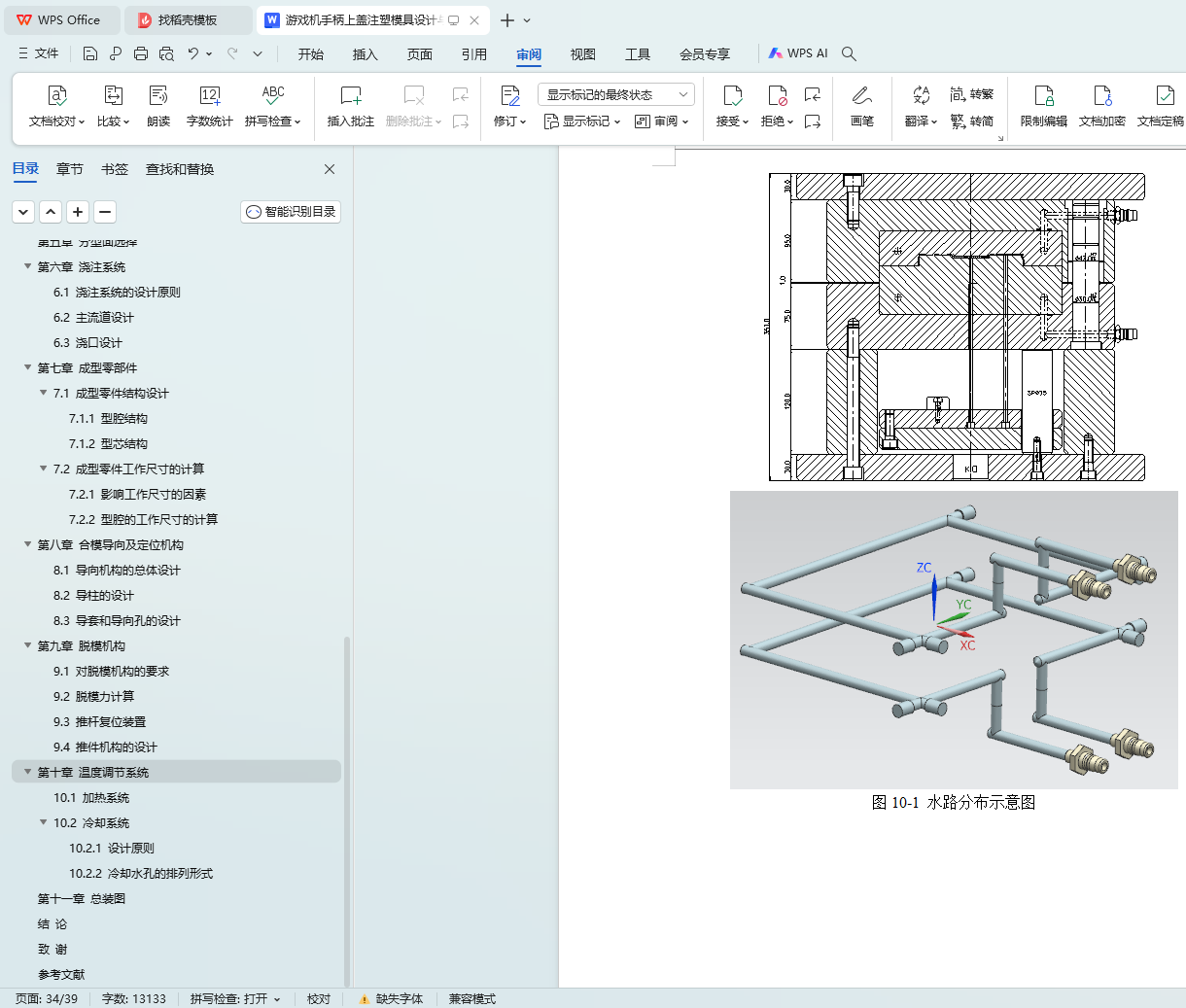

在模具设计过程中,特别关注了模具的冷却系统、脱模机构、导向定位机构等关键部件的优化设计,以提高模具的成型效率和产品质量。最终,完成了模具的详细设计图纸和说明书,为实际生产提供了可靠的技术支持。

关键词:ABS塑料;注塑模具设计;游戏机手柄上盖;模具优化;冷却系统;脱模机构

Abstract

With the increasingly important role of mold technology in modern industry, it plays an indispensable role in promoting the development of national economy. Especially in the rapid development of automobile manufacturing, medical production, electrical electronics and other fields, the application of mold technology is particularly extensive. As an important part of mold technology, the market share of plastic products continues to rise due to its good performance and economy. In the future, with the promotion of industry 4.0 and intelligent manufacturing, the market prospect of mold technology will be broader.

The graduation design takes the top cover of the game controller to design and optimize the injection mold. As a key component of home electronic products, the design of the controller cover should not only need to meet the functional requirements, but also take into account the appearance and user experience. Therefore, this design first carried out a detailed process analysis of the product, including the use of requirements, appearance requirements, etc., and selected ABS plastic as the raw material. Then, the key steps of mold typing surface selection, type cavity layout, gate design and size calculation of molding parts are conducted. At the same time, according to the injection molding volume, injection pressure and other parameters, the injection molding machine model was reasonably selected and checked.

In the process of mold design, special attention is paid to the optimization design of key components such as cooling system, release mechanism and guide positioning mechanism, so as to improve the molding efficiency and product quality. Finally, the detailed design drawings and instruction manual of the mold were completed, which provided reliable technical support for the actual production.

Key words: ABS plastic; injection mold design; top cover of game controller; mold optimization; cooling system; mold release mechanism

目录