斜三通管塑件注塑模具设计 说明书(论文)+CAD图纸+proe三维图

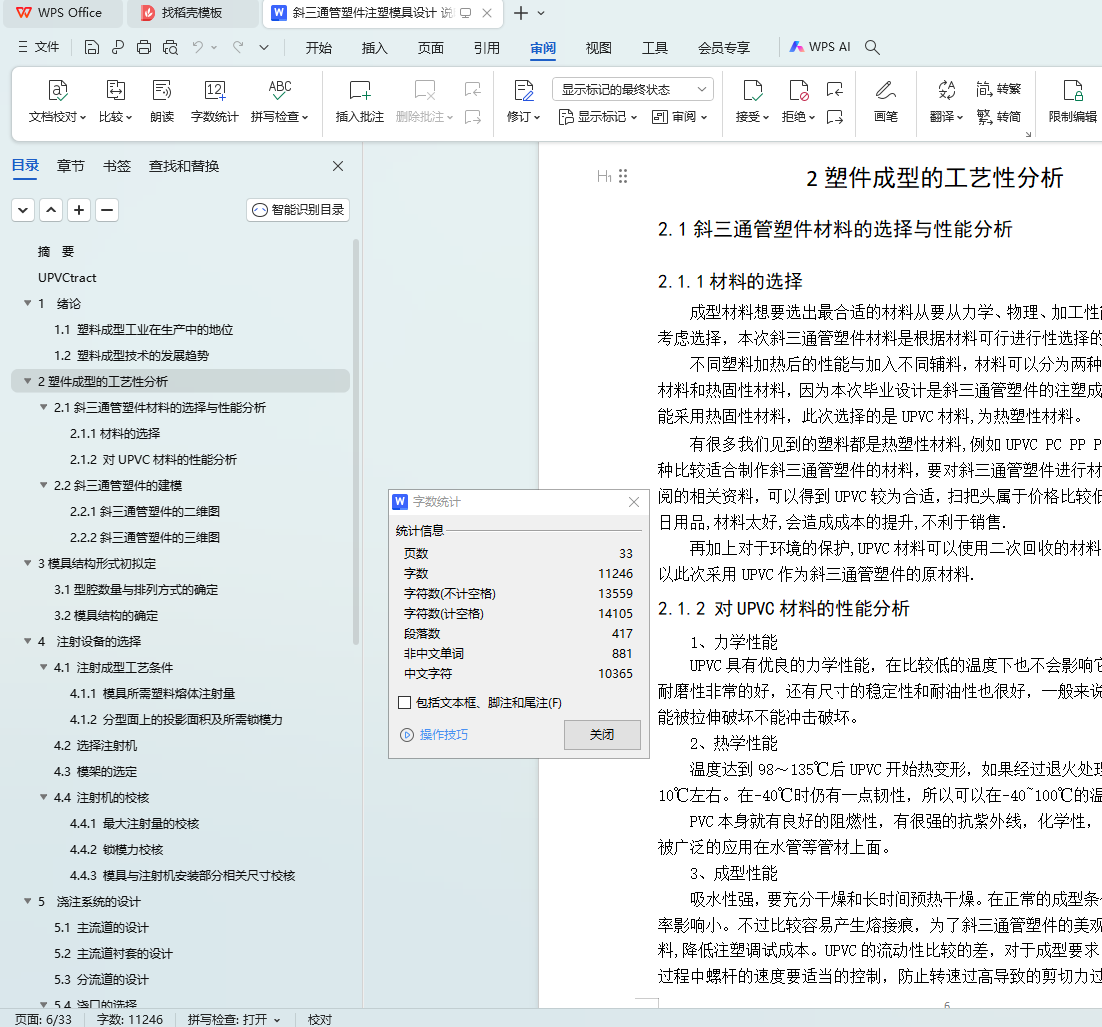

摘 要

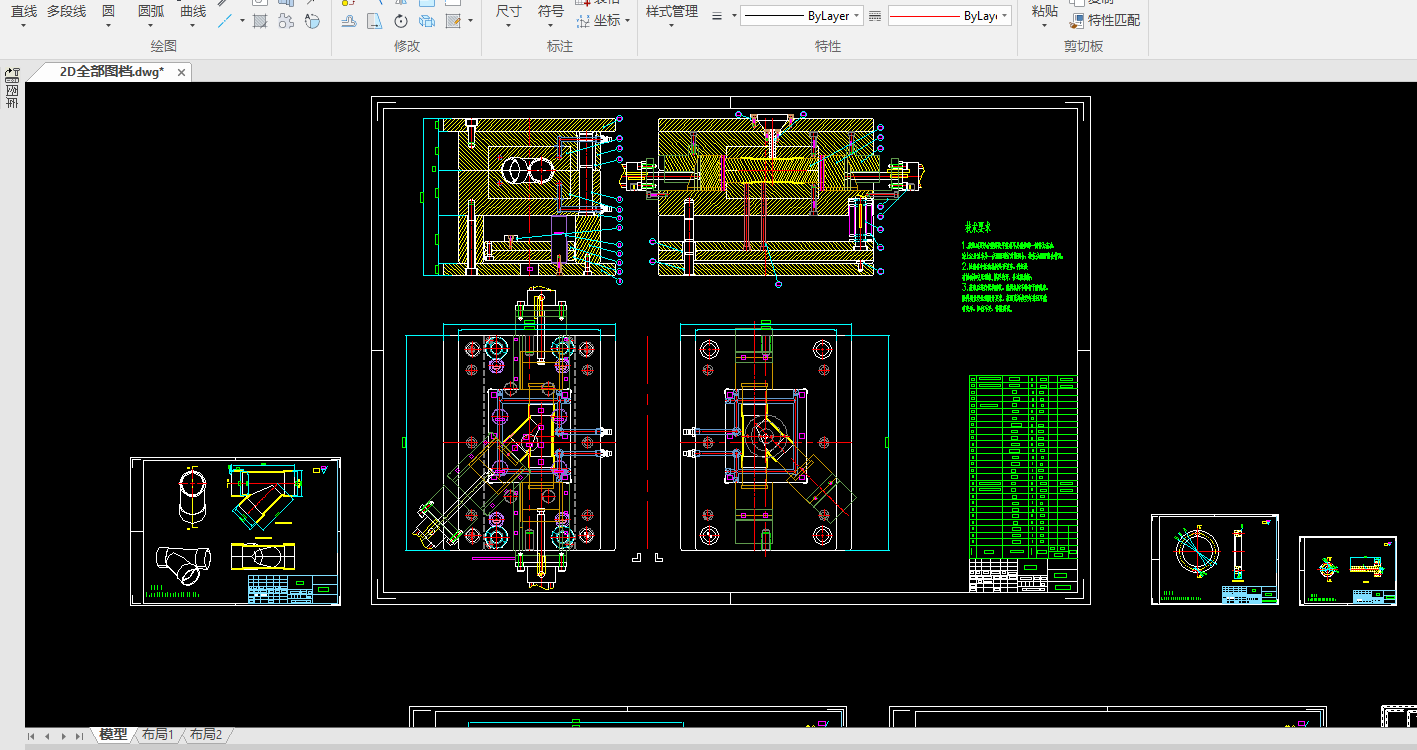

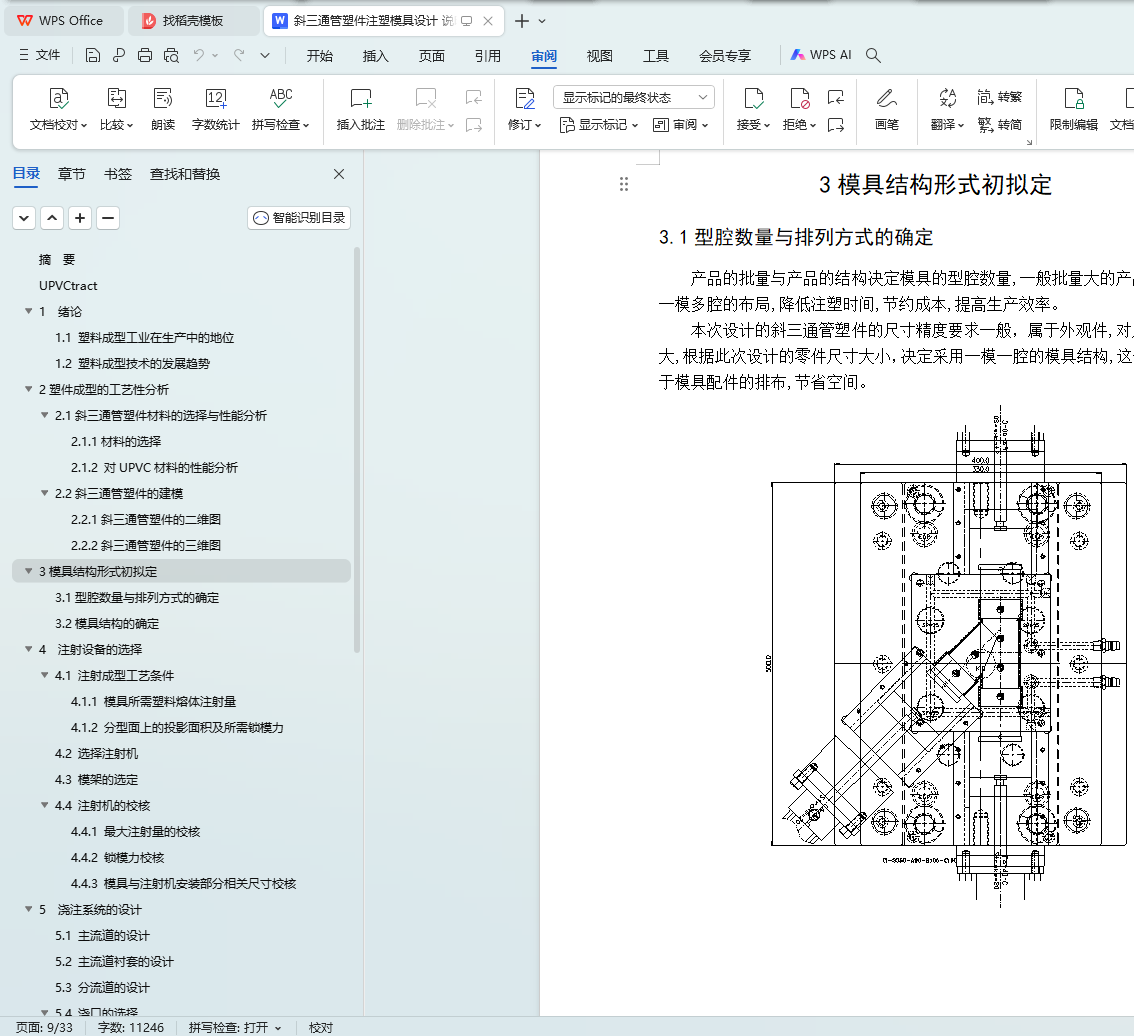

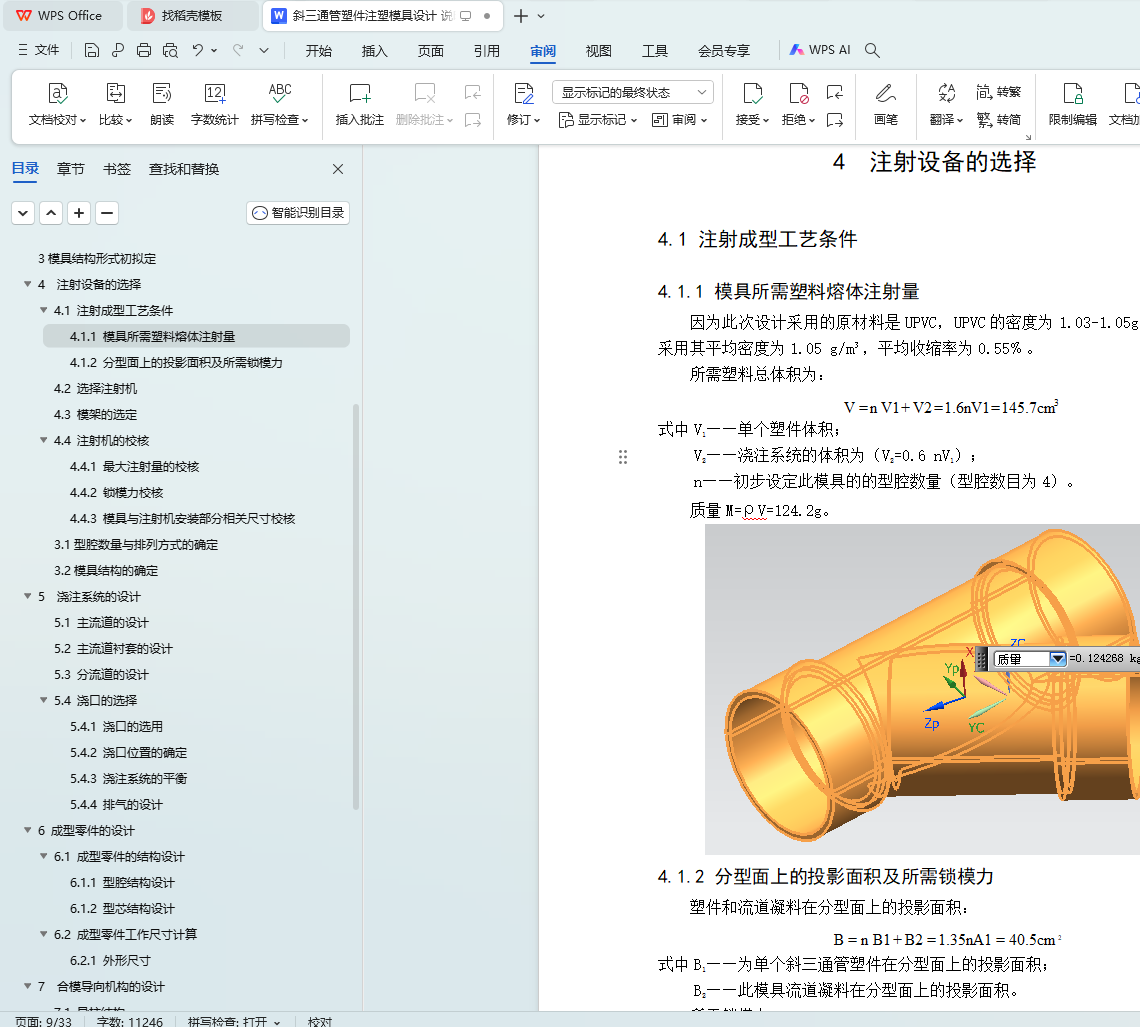

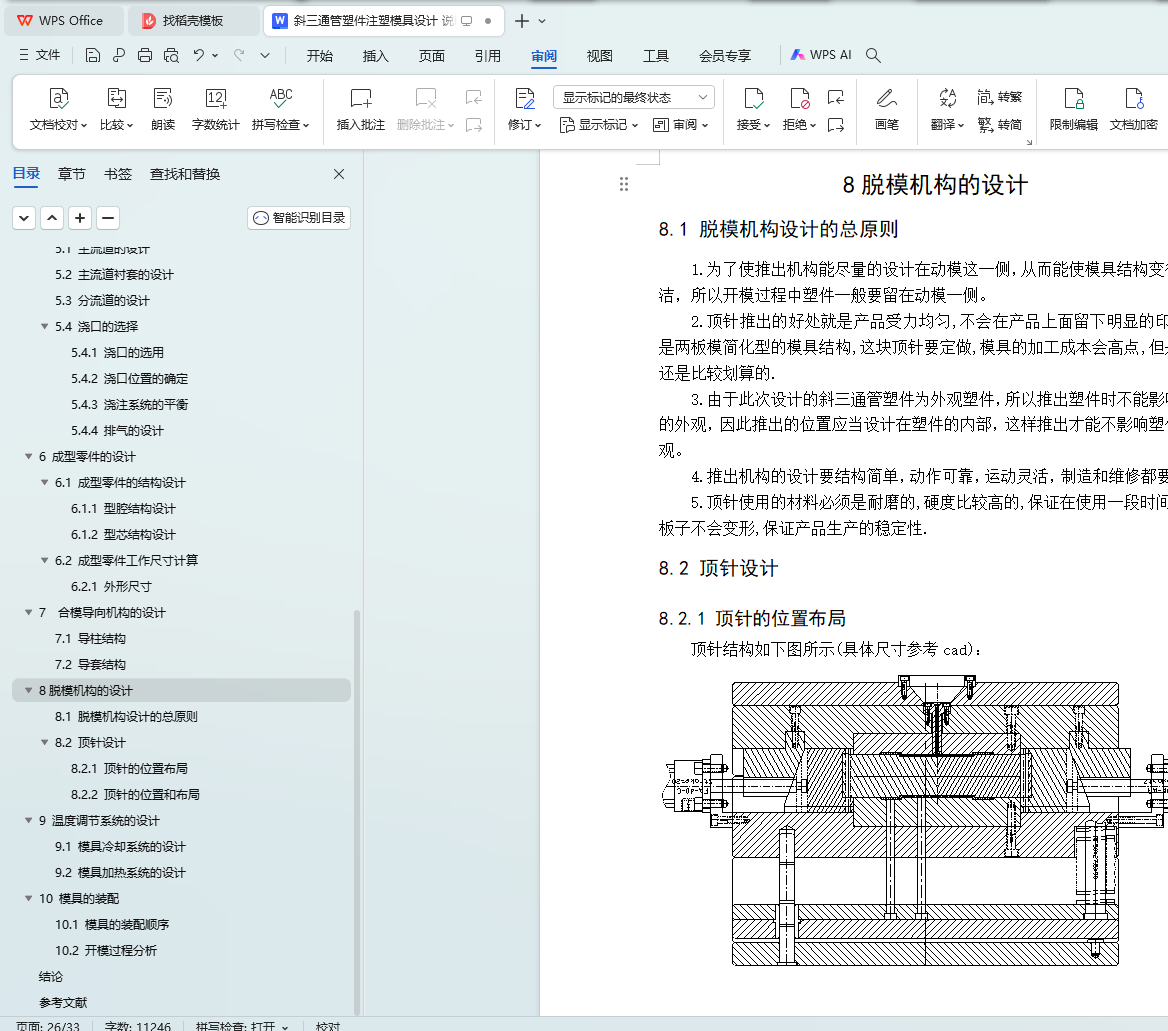

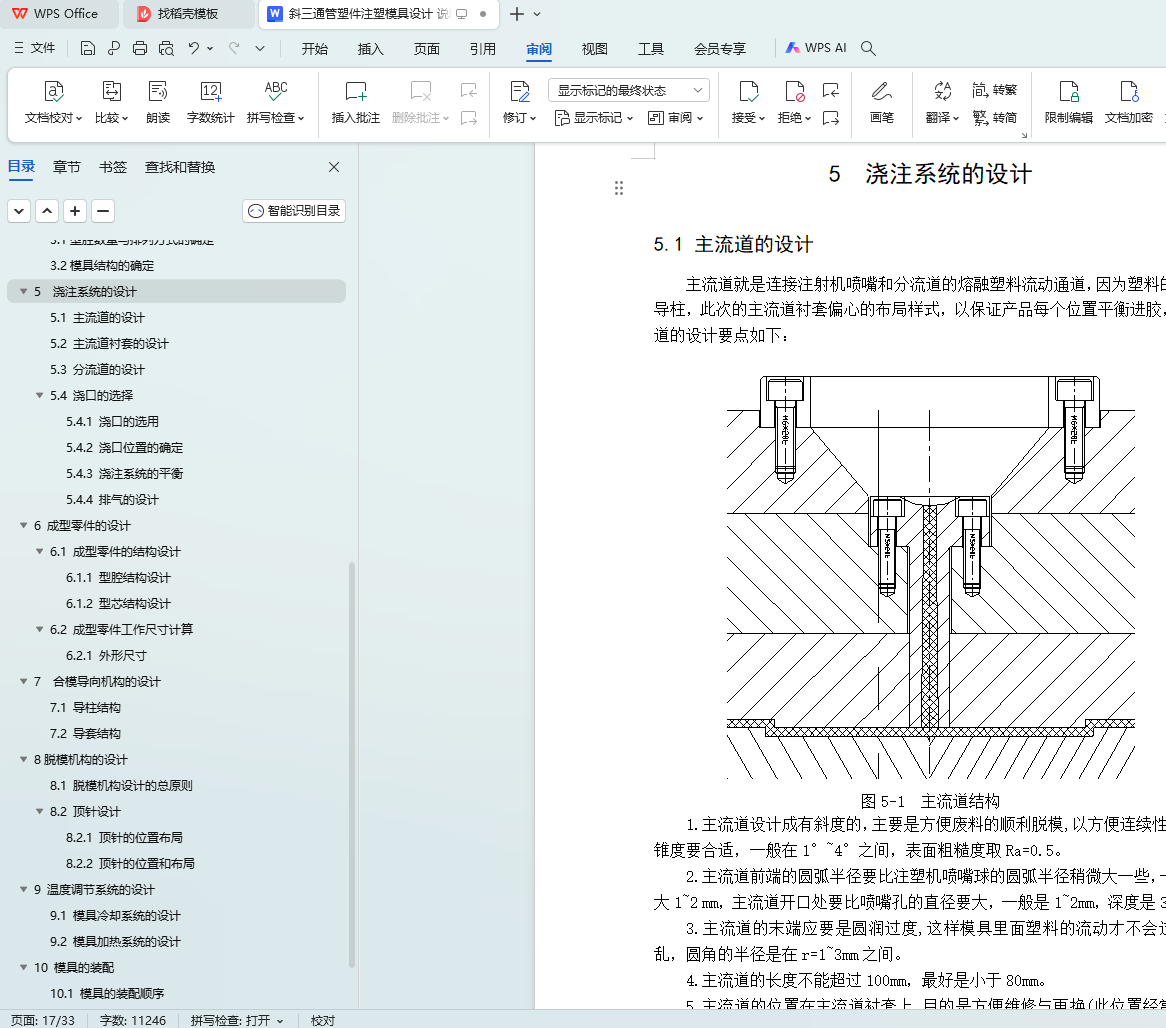

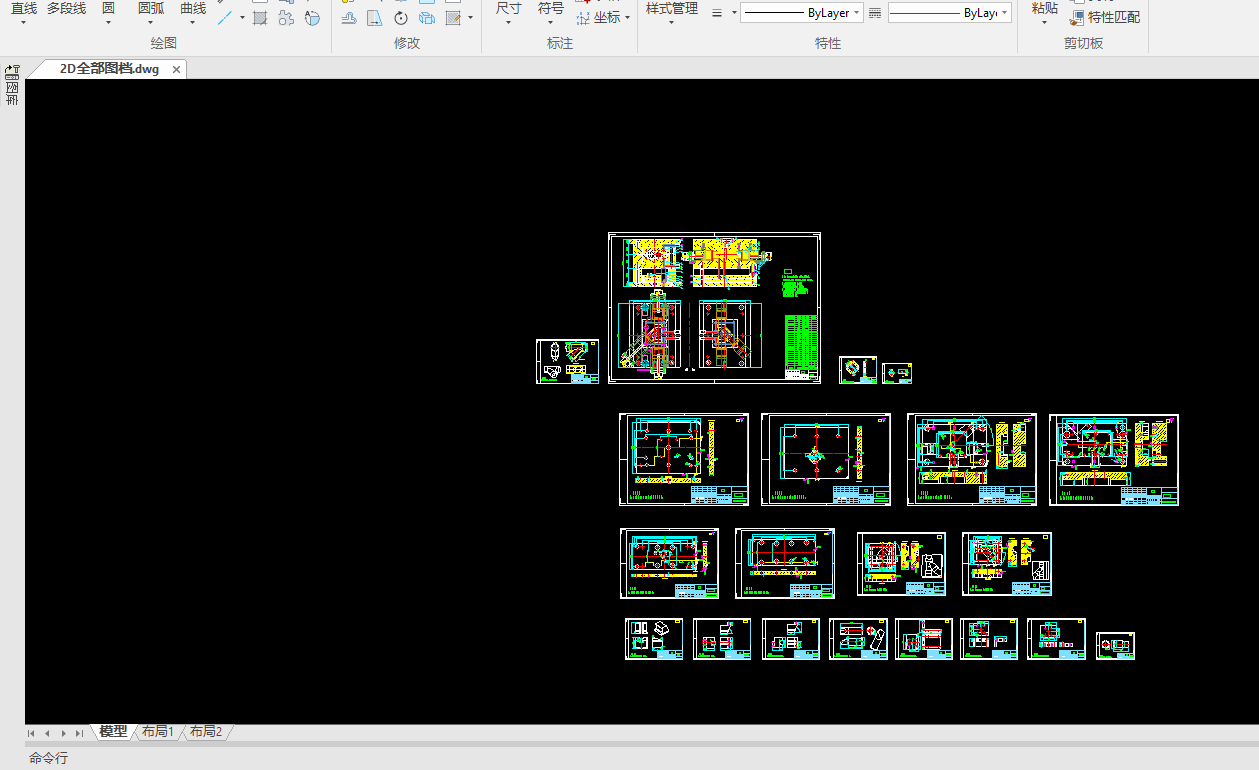

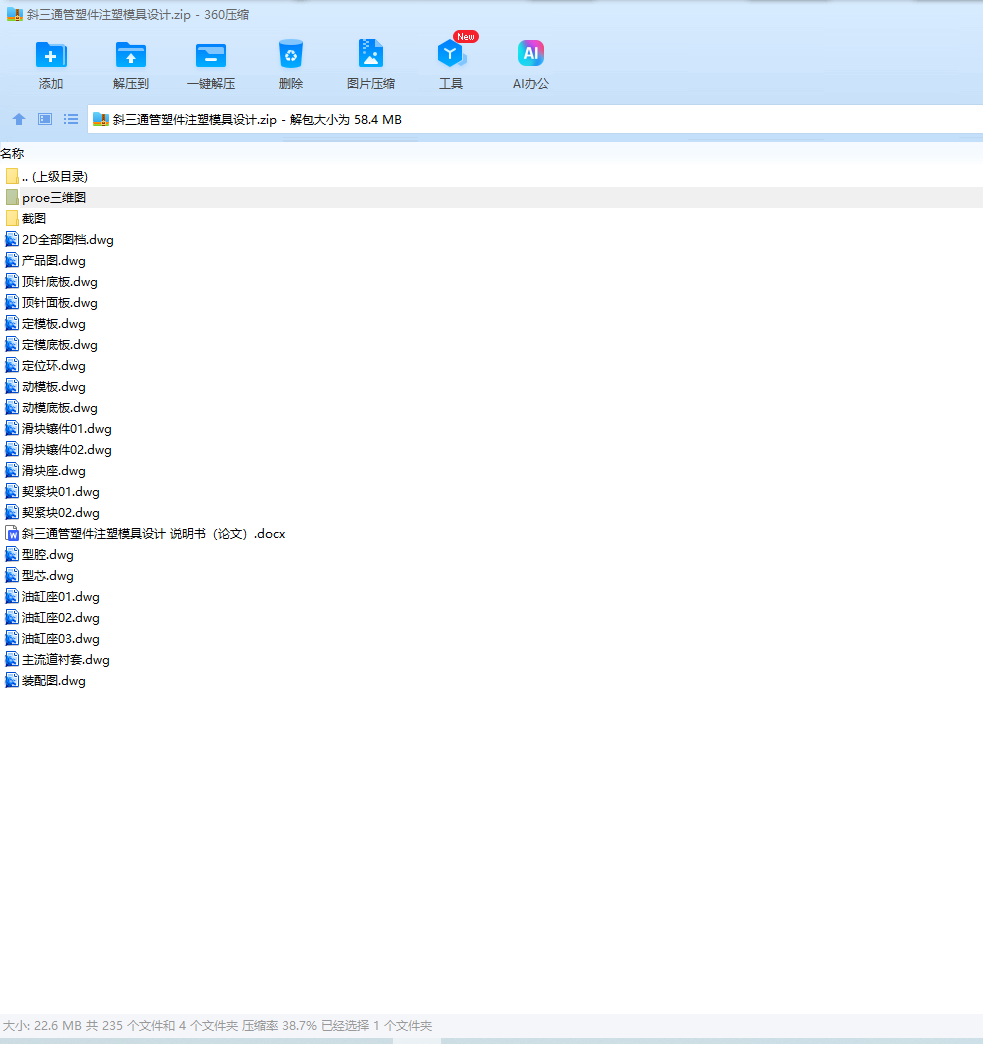

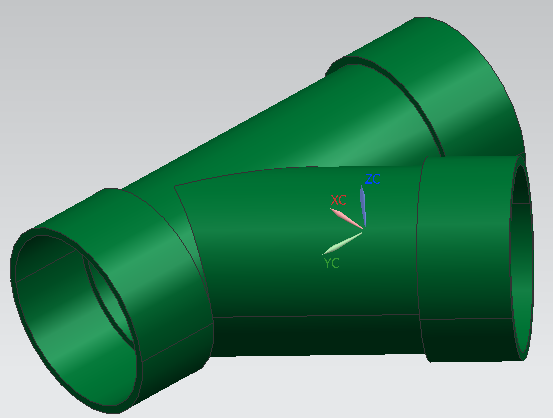

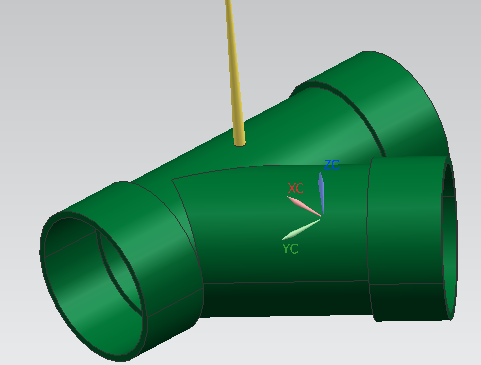

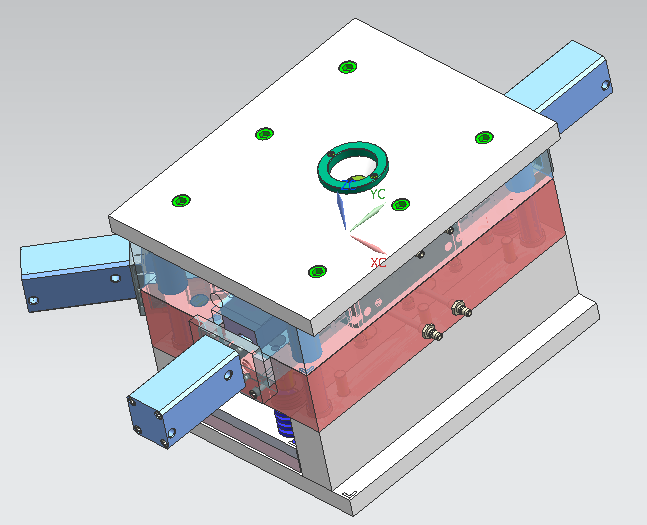

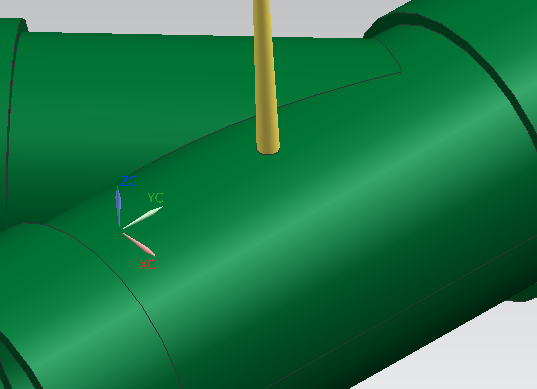

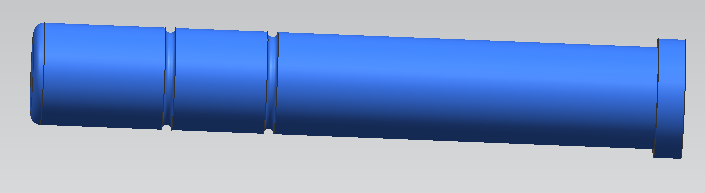

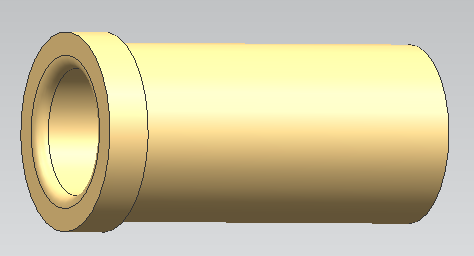

塑料是一种高合成分子材料,塑料的特点具体的有:重量轻且还坚固,有较好的耐化学腐蚀性,还有很好的电绝缘性,价格相对来说很便宜,且具有很好的可塑性。在现在的生活中塑料是一种不可缺的产品,现在人们常用的手机、电脑、汽车、家用电器等产品都需要用到塑料制品。塑件成型的方法有很多种,注塑成型只是其中一种。本次毕业设计用到的就是注塑成型法,注塑成型就是利用注塑机将热塑料溶体在高速的条件下注射到模具中去,再经过冷却固化获得产品。注射具有许多优点,例如:生产的效率很高,速度很快,可执行自动化操作,还可以成型形状复杂的零件,可以大量生产产品。 本次毕业设计的零件是斜三通管塑件,特点是:重量很轻,强度很高,具有较好的耐腐蚀性,需要大批量生产。此次毕业设计要先对零件进行工艺可行性分析,再选择注塑机,模架。然后再确定各零件尺寸,进一步设计型腔、型芯、浇注系统、脱模系统等。本次毕业设计主要用UG绘制三维图,采用CAD来制作装配零件图。

关键词:模具设计、斜三通管塑件、注塑模具、UPVC

UPVCtract

Plastics are a kind of high synthetic molecular material. The characteristics of plastics are light weight, strong strength, good resistance to chemical corrosion, good electrical insulation, relatively cheap price and good plasticity. Plastic is an indispensable product in our daily life. Now people often use plastic products in mobile phones, computers, automobiles, household appliances and other products. There are many methods of forming plastic parts, and injection molding is only one of them. This graduation project is using injection molding method, injection molding is the use of injection molding machine to inject hot plastic solution into the mold under high-speed conditions, and then through cooling and solidification to obtain products. Injection has many advantages, such as high efficiency, high speed, automatic operation, complex shape parts and mass production. This graduation project's spare parts are mobile phone back shell, which is characterized by light weight, high strength, good corrosion resistance, and need mass production. This graduation design first carries on the craft feasibility analysis to the spare parts, then chooses the injection molding machine, the mold frame. Then determine the size of each part, and further design the cavity, core, gating system, demoulding system and so on. This graduation project mainly uses UG to draw three-dimensional drawings, and uses CAD to make assembly parts drawings.

Key words: mold design; plastic; injection mold,;UPVC

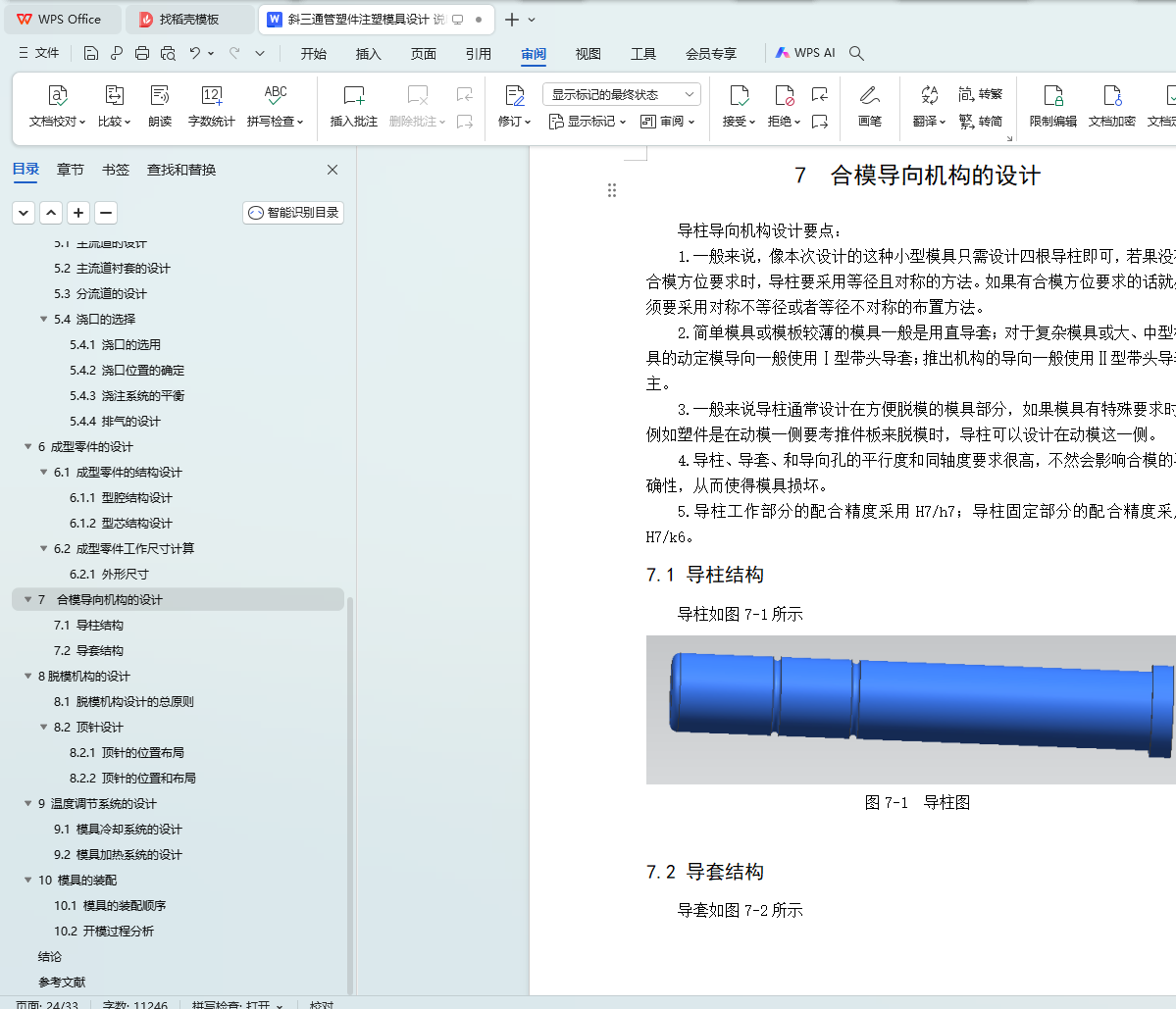

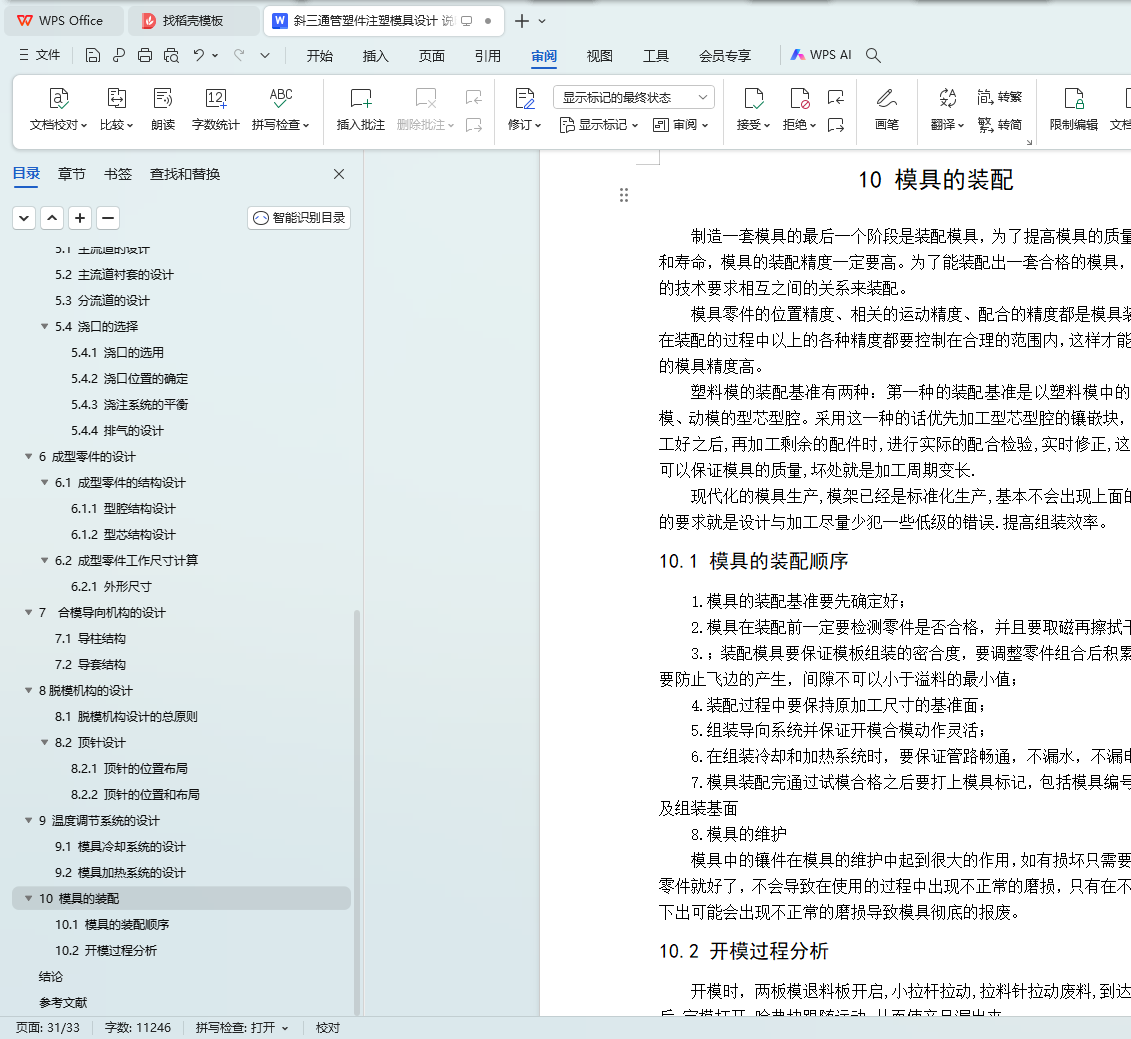

目录