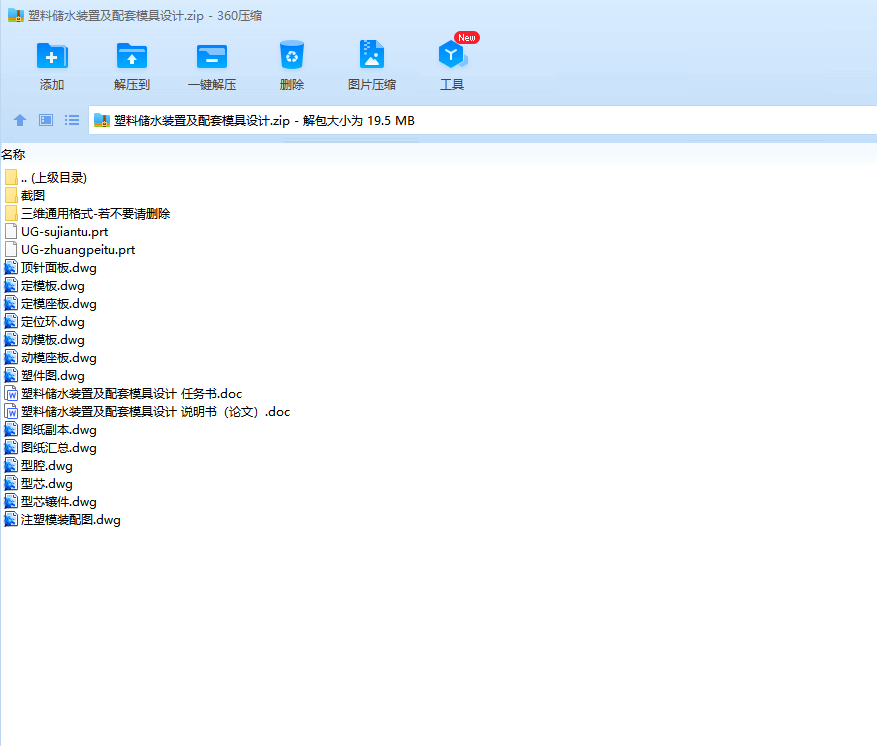

塑料储水装置及配套模具设计 说明书(论文)+任务书+CAD图纸+UG三维图

摘要

20世纪塑料材料的制品如雨后春笋一样涌现,当然这样的兴起是因为它本身的特点,包括有价格低廉、易塑型、强度大等等。就现在来说,塑料制品已经在很多的方面得到了应用,诸如日常的生活、医疗所使用的设备、电子电器制品方面、汽车内部设备等。

塑料制品有很多种成型的方法,本设计使用的是最常使用的注塑方式――注射成型,进行塑料水箱注塑模模具设计。

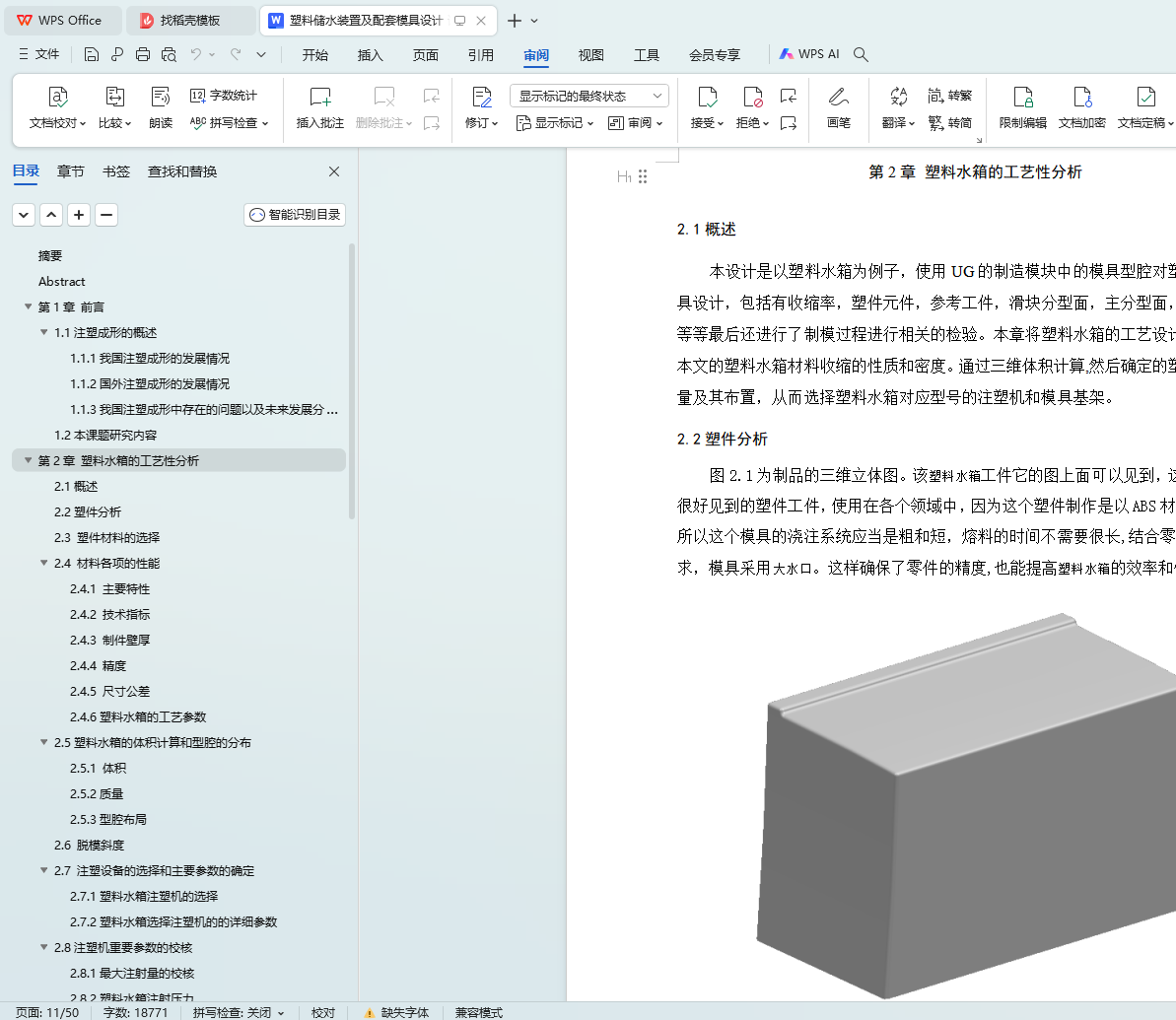

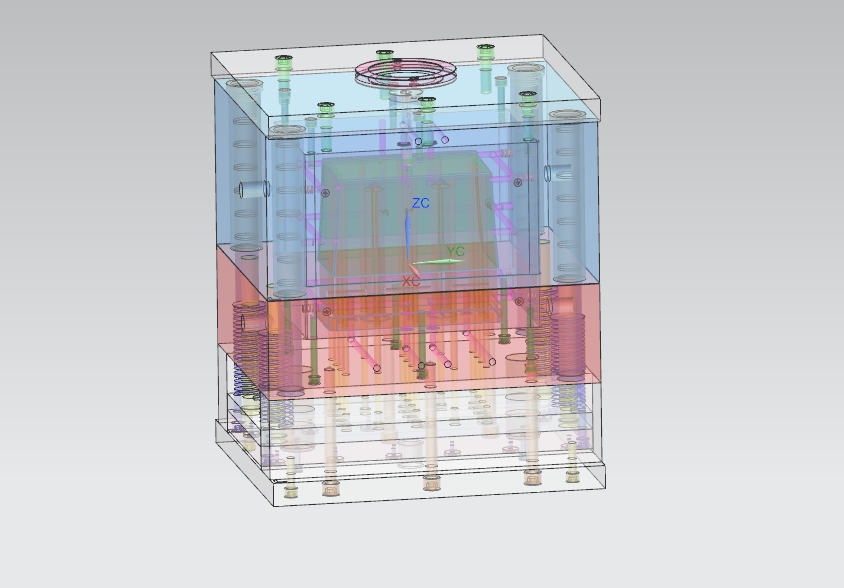

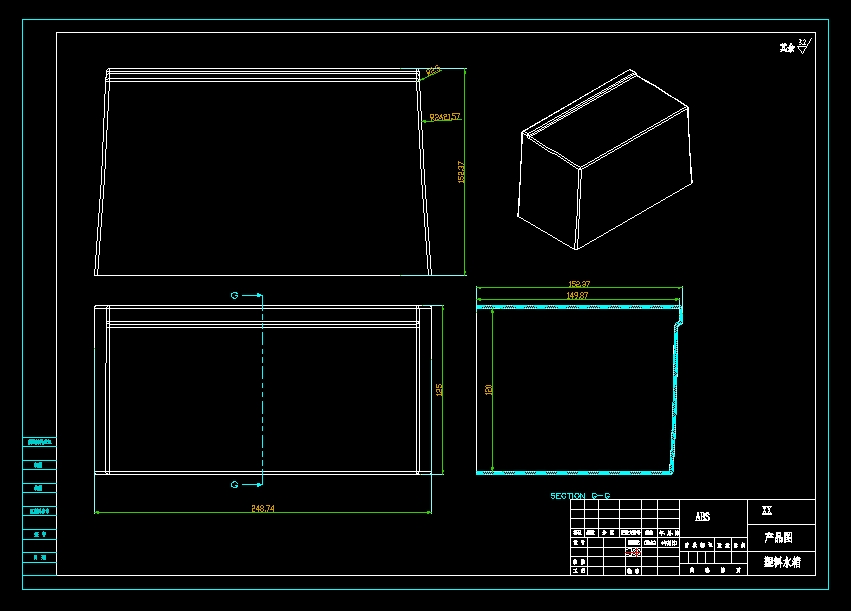

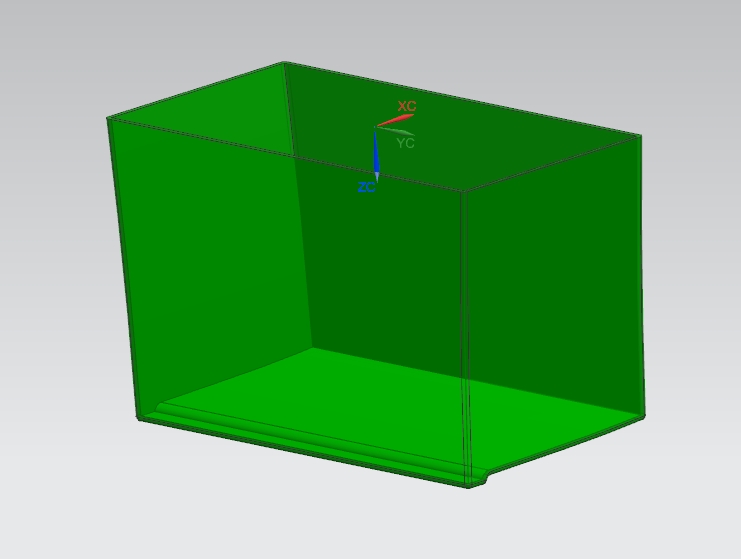

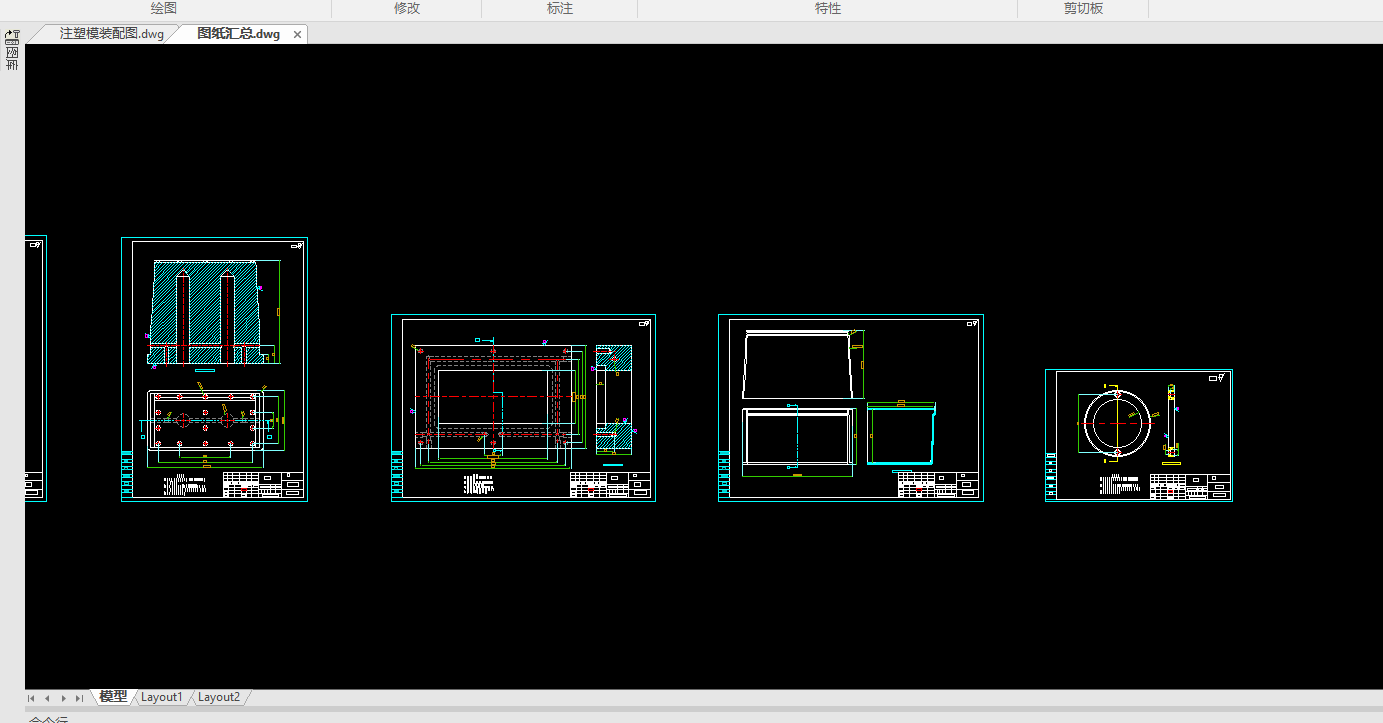

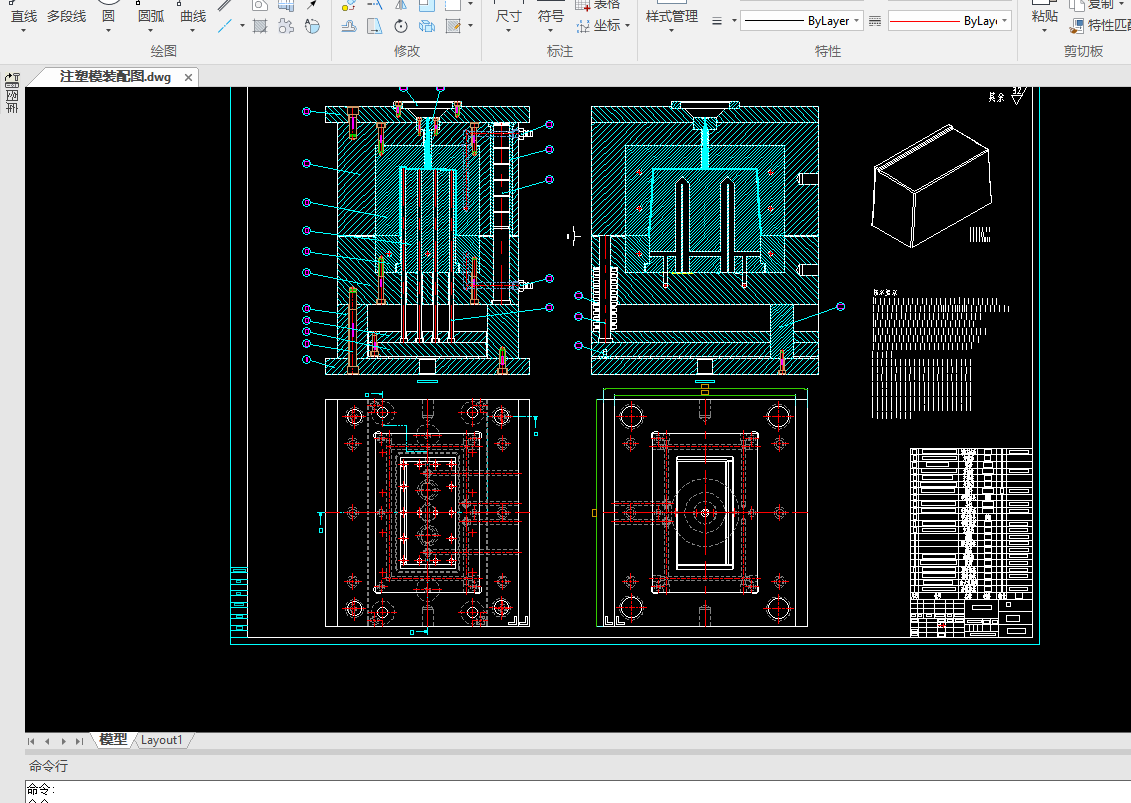

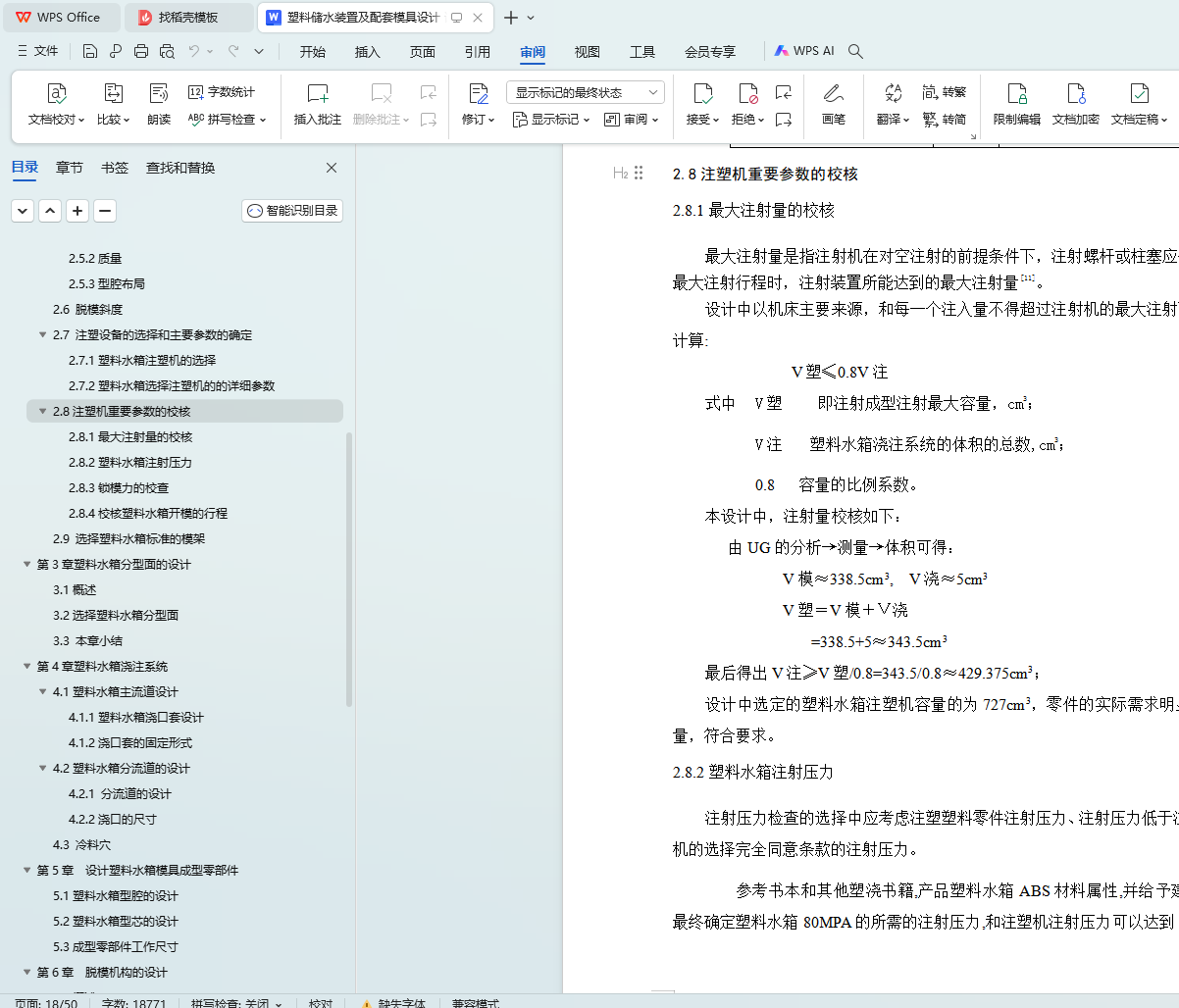

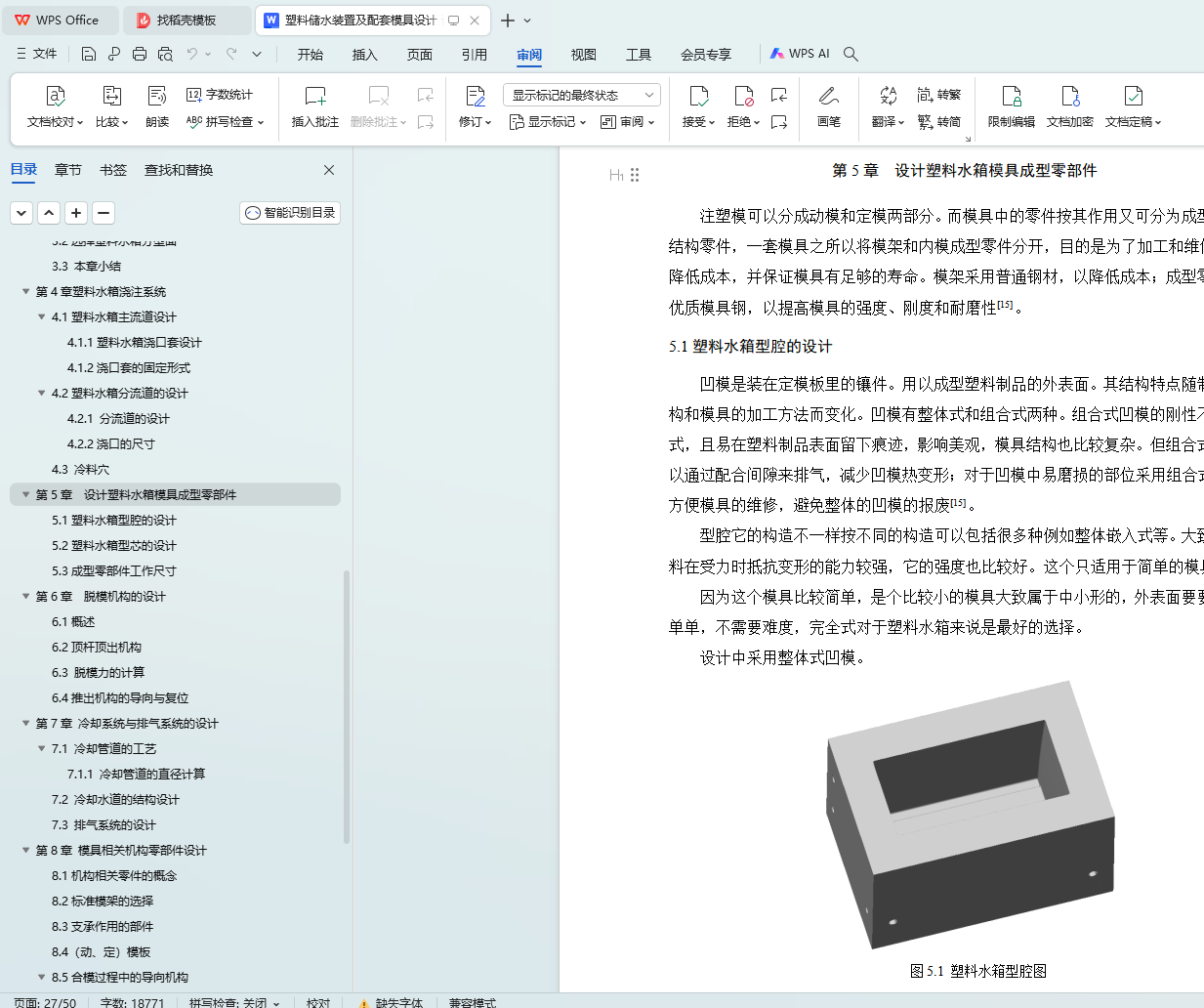

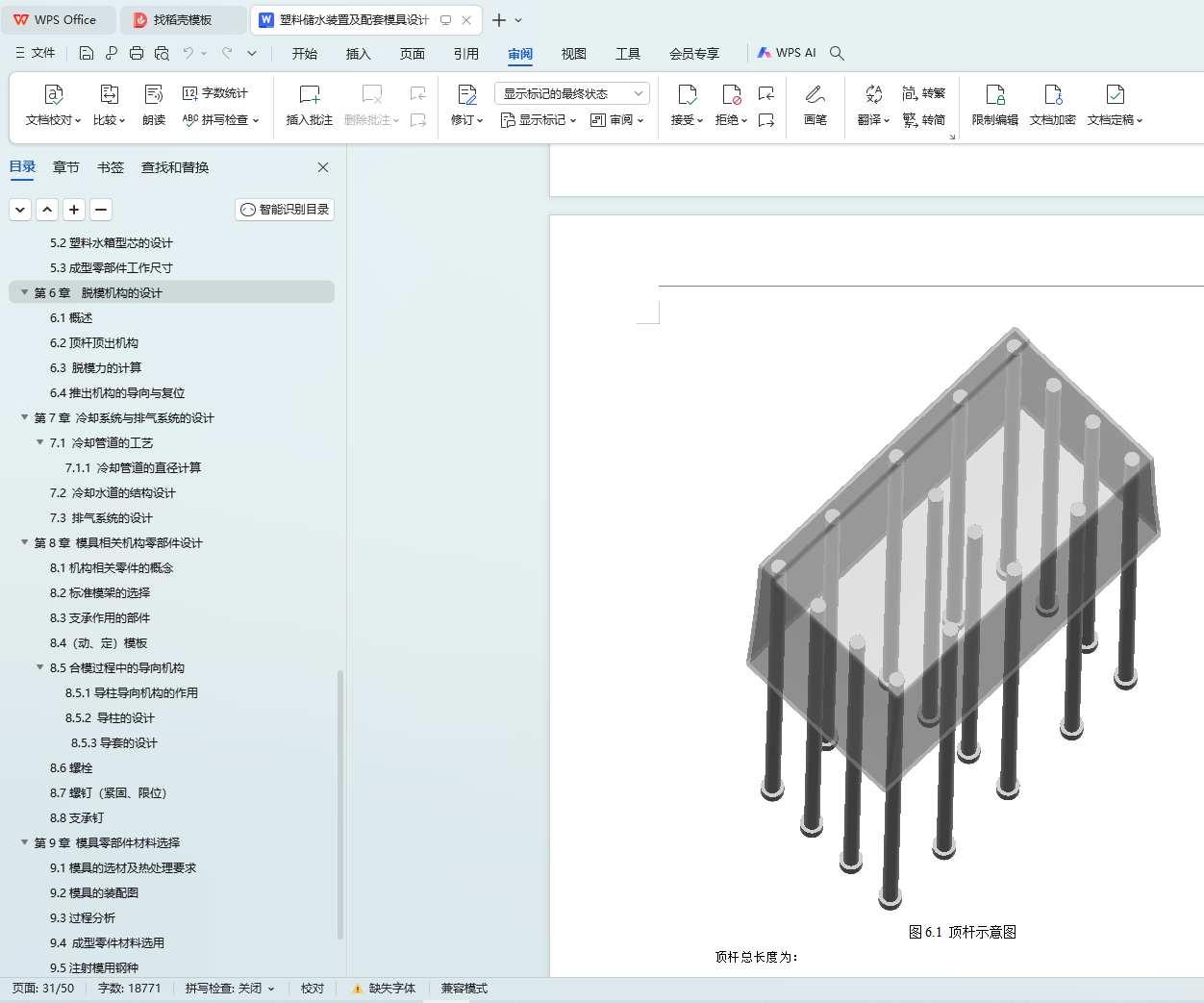

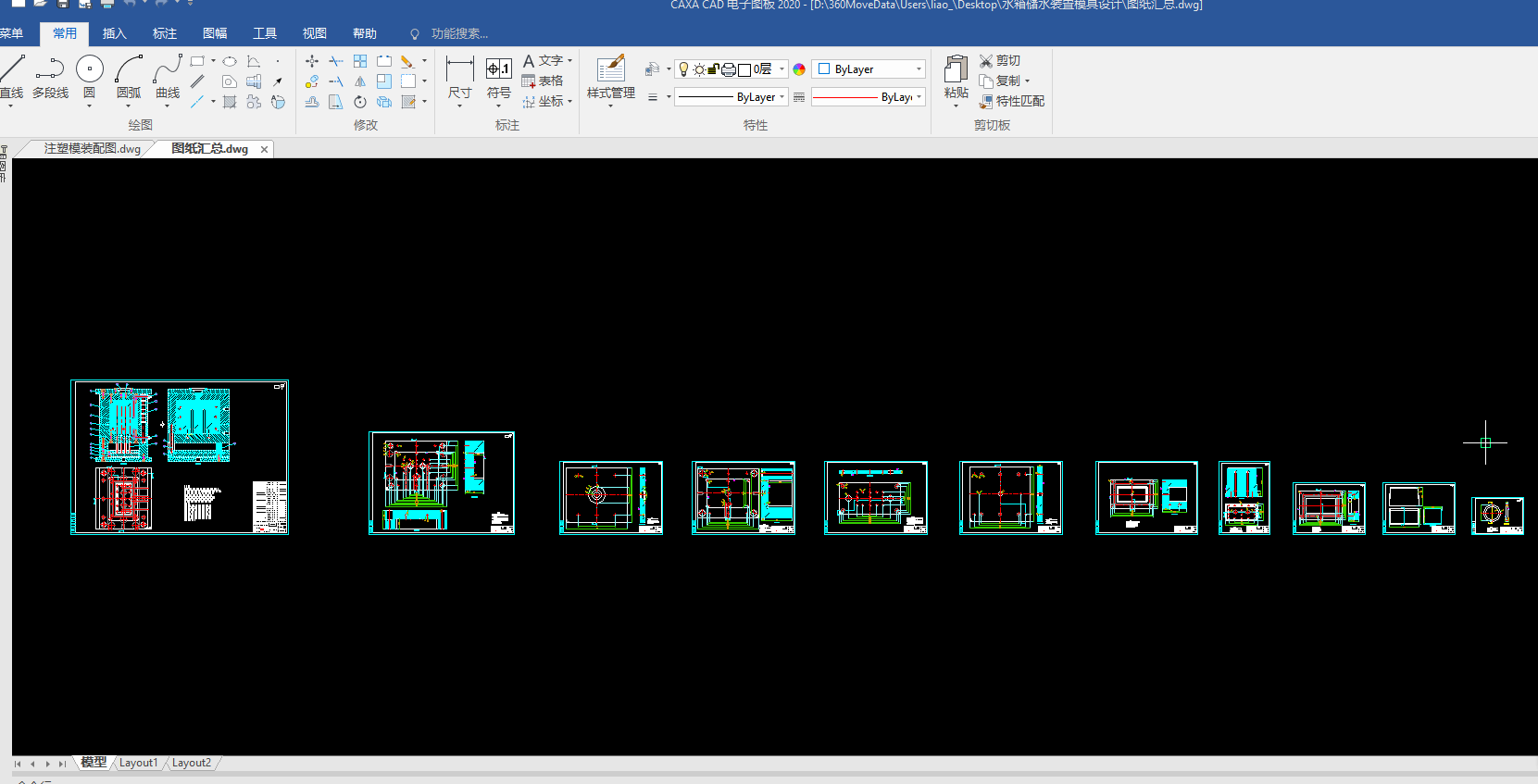

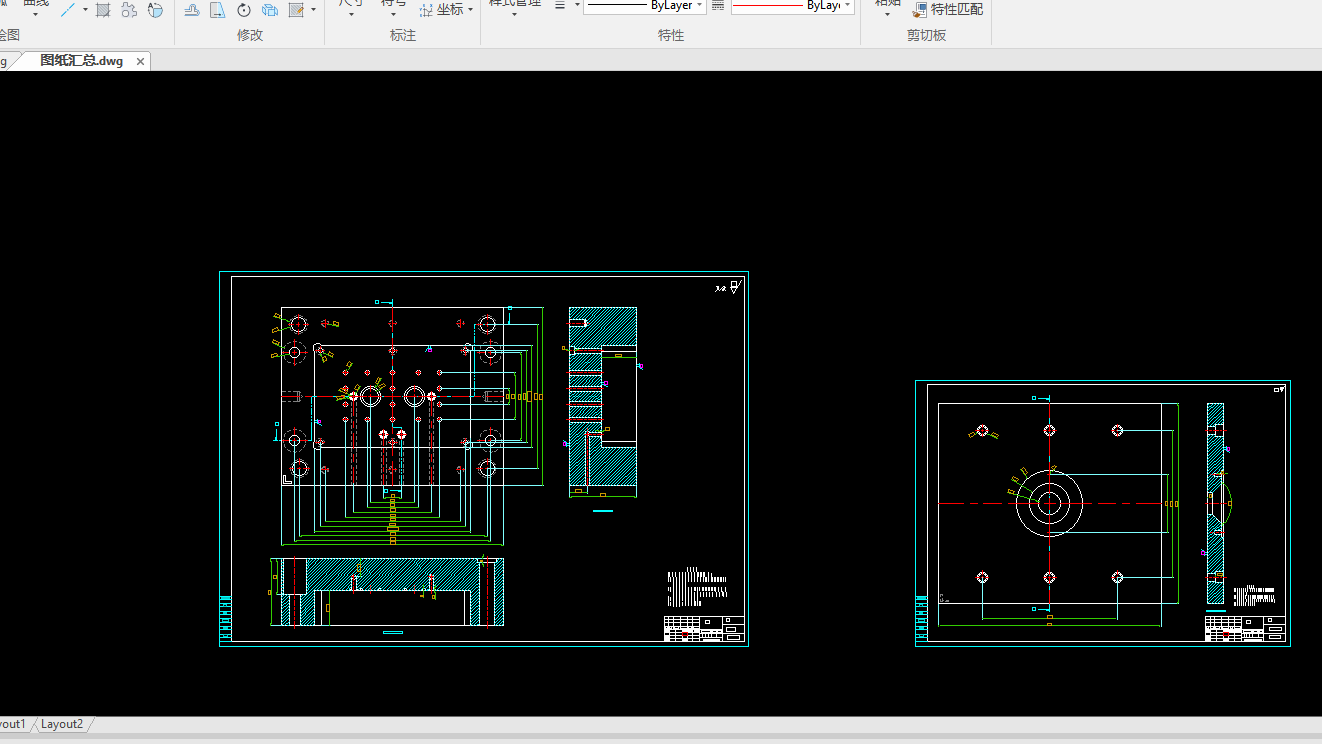

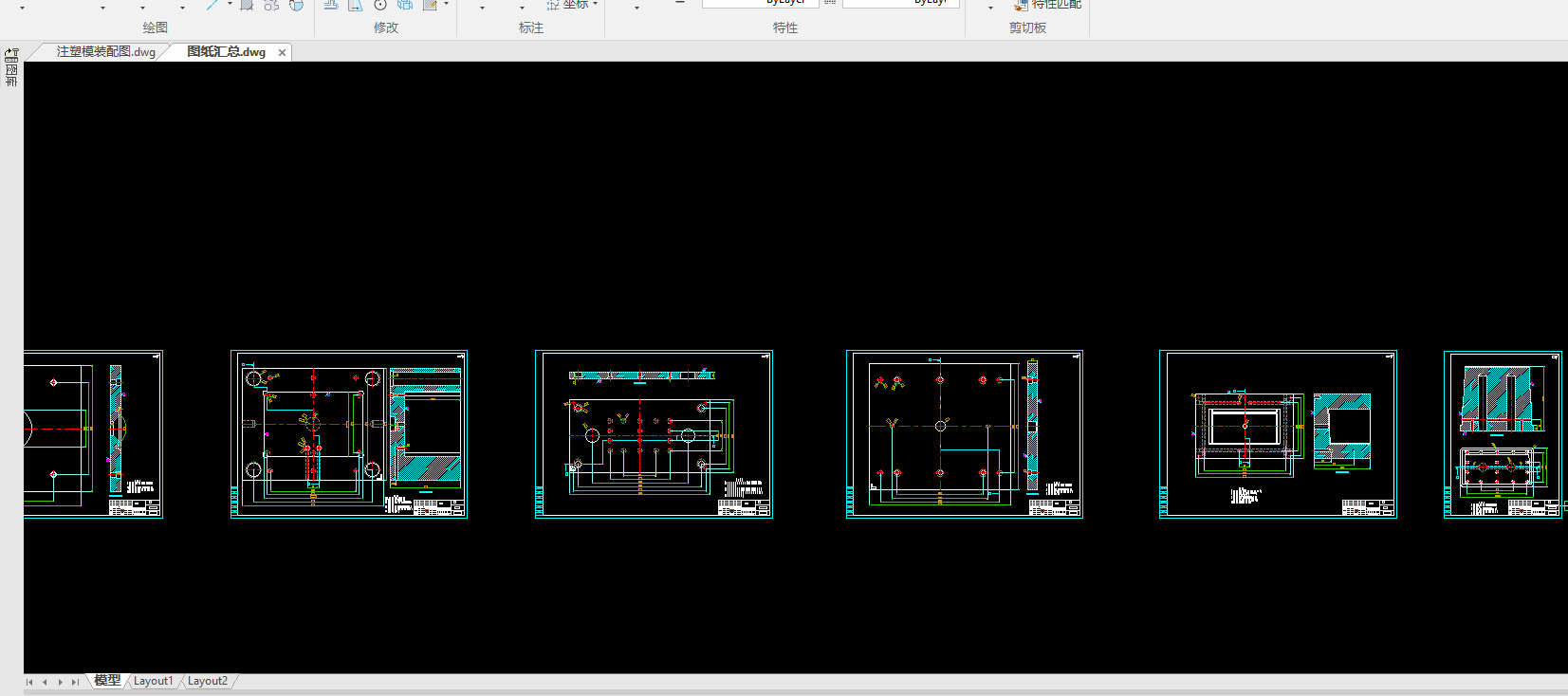

本设计的模具设计对象为塑料水箱,前期对于设计对象进行了相关的测量,数据的记录等;中期主要是使用UG三维设计软件根据前期测量的数据建立立体模型,并在塑件模型的基础上利用UG制造内的模具型腔模块对塑料水箱作出相应的注塑模模具设计,包括有塑件元件、滑块分型面、主分型面、浇口等,并且加入相应的模架、浇口、流道等;后期则是以之前作出的成果为基础使用CAD软件绘制出相应的二维图,也就是工程图,更加清晰的显示出塑件的结构以及模具的机构。

关键词:塑料水箱;注塑模;滑块分型面;主分型面

Abstract

In twentieth Century, the products of plastic materials sprang up like mushrooms, of course, because of its own characteristics, including low price, easy molding, high strength and so on. For now, plastic products have been used in many ways, such as daily life, medical equipment, electrical and electronic products, automotive equipment and so on.

There are many plastic molding methods, the design is the most commonly used injection molding - injection molding, plastic tank injection mold design.

The object of the design for the mold design for plastic water tank, preliminary design objects were related to the measurement data records; interim is mainly to establish three-dimensional model according to the measured data using UG 3D design software, and make the corresponding injection mould design of plastic water tank using the mold cavity module UG in plastic manufacturing base a model, including plastic element, slider type face, the main parting line, gate, and add the corresponding mold gate runner; the latter is to make the results before rendering the 2D map corresponding to the basis of the use of CAD software, which is the engineering diagram, show the structure of plastic parts and die mechanism more clear.

Key words: plastic water tank; injection mold; slide parting surface; main parting surface

目 录