灭火器注塑模具设计 说明书(论文)+任务书+cad图纸+三维

摘 要

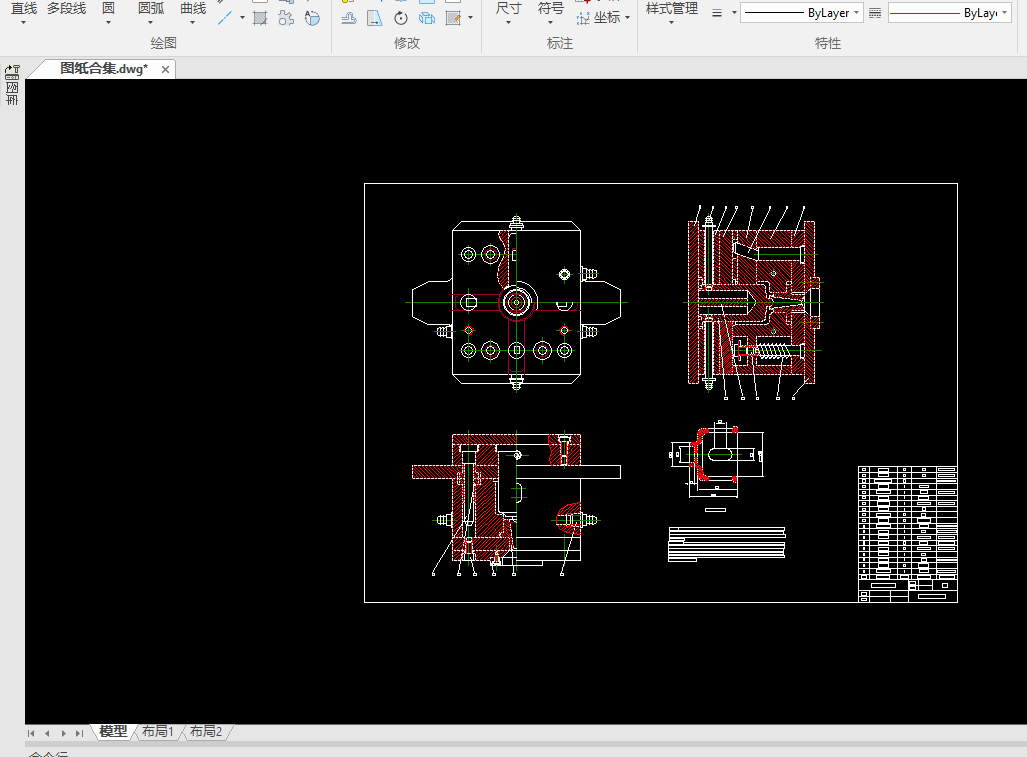

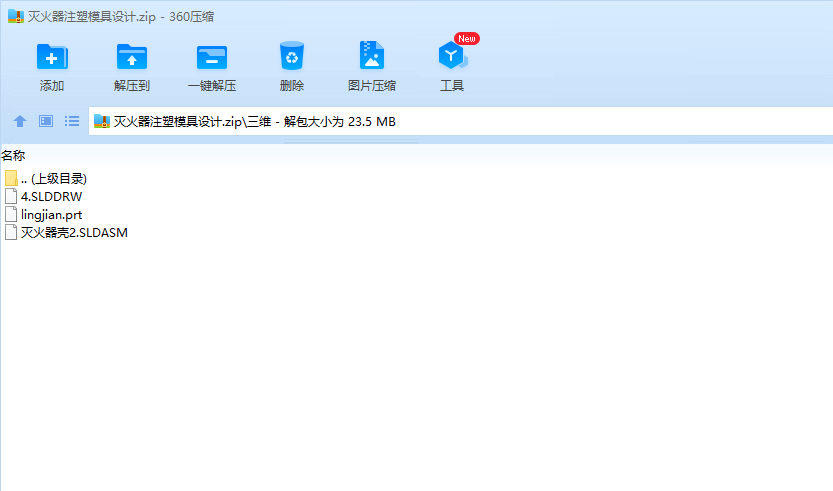

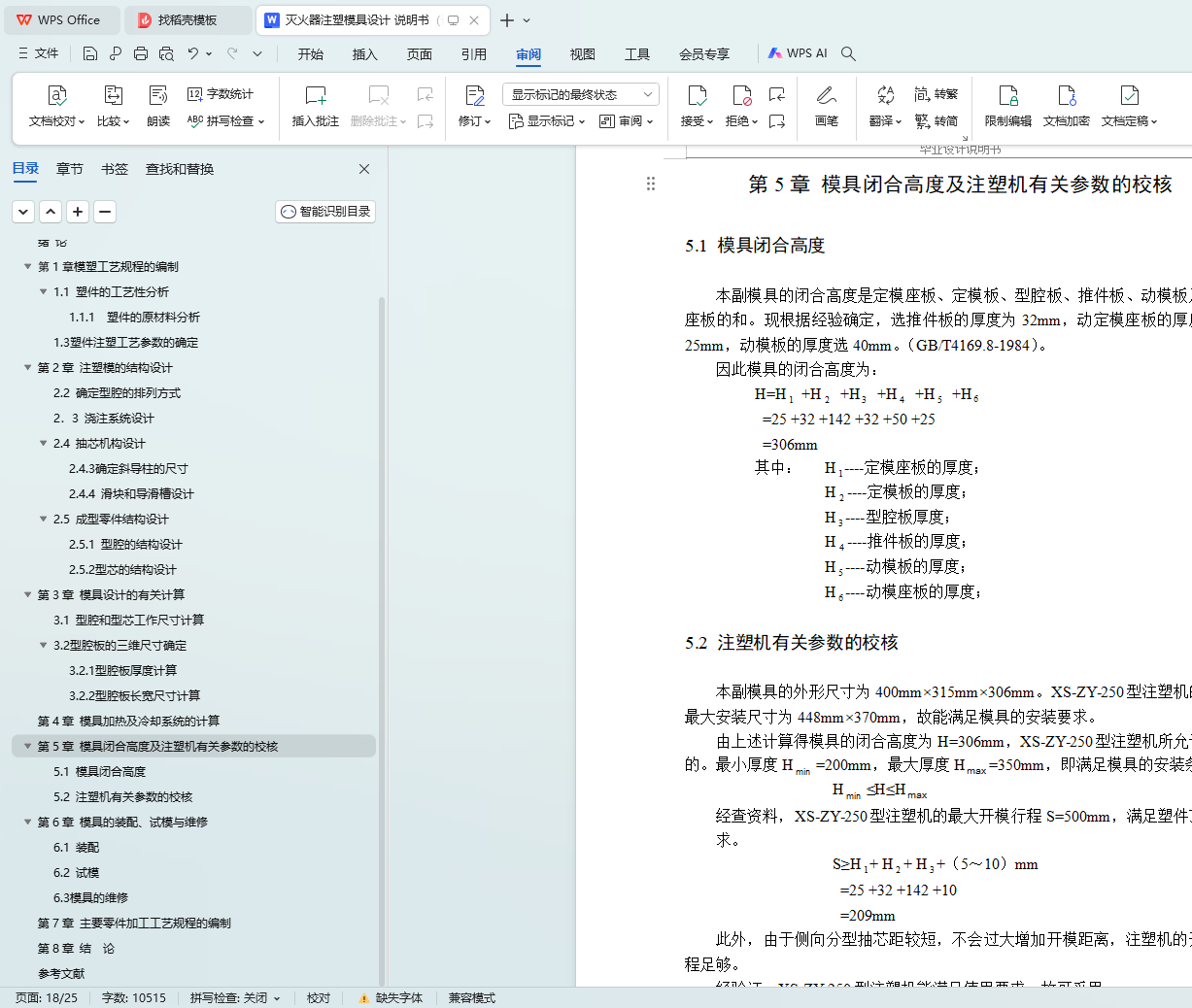

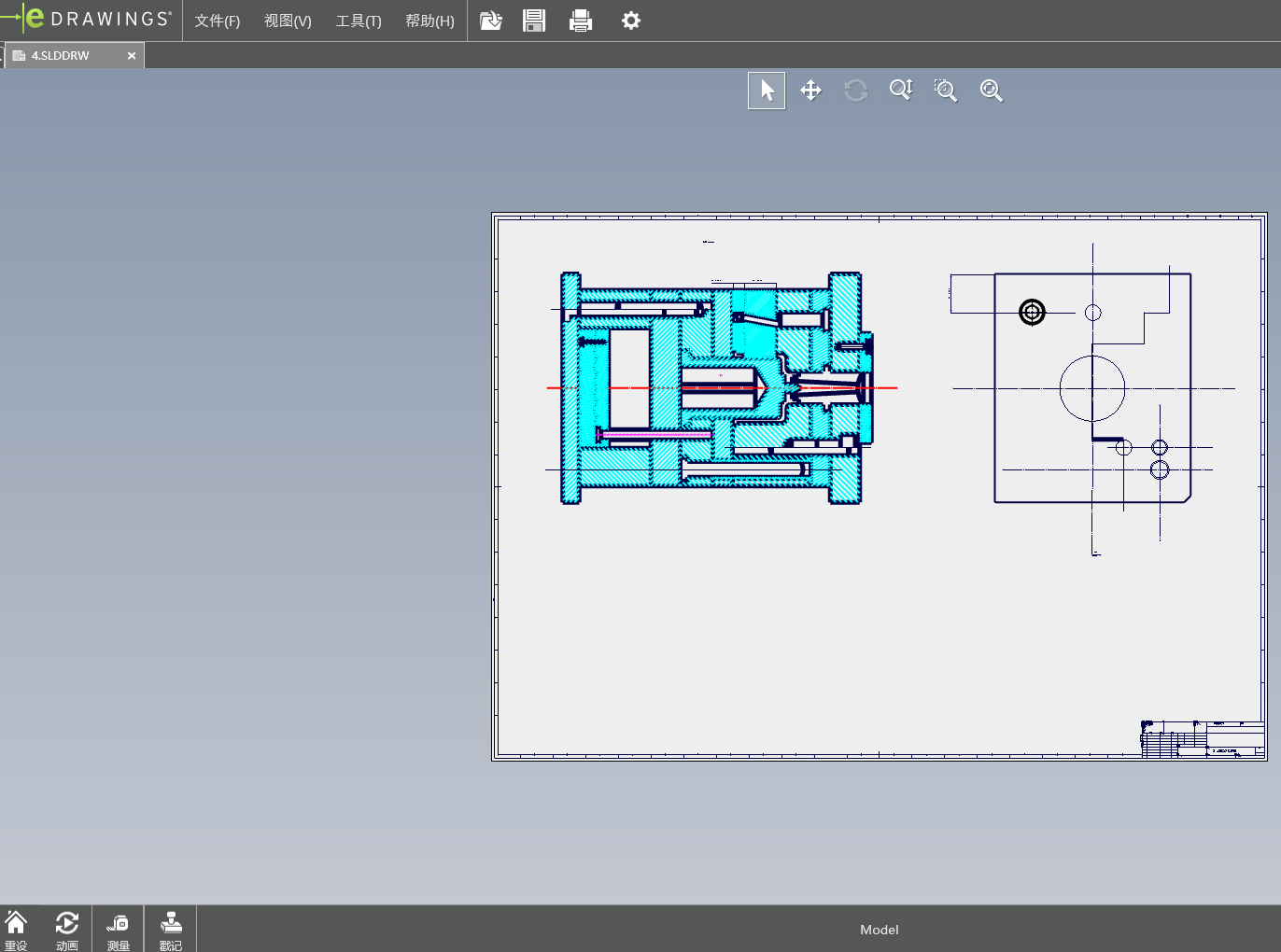

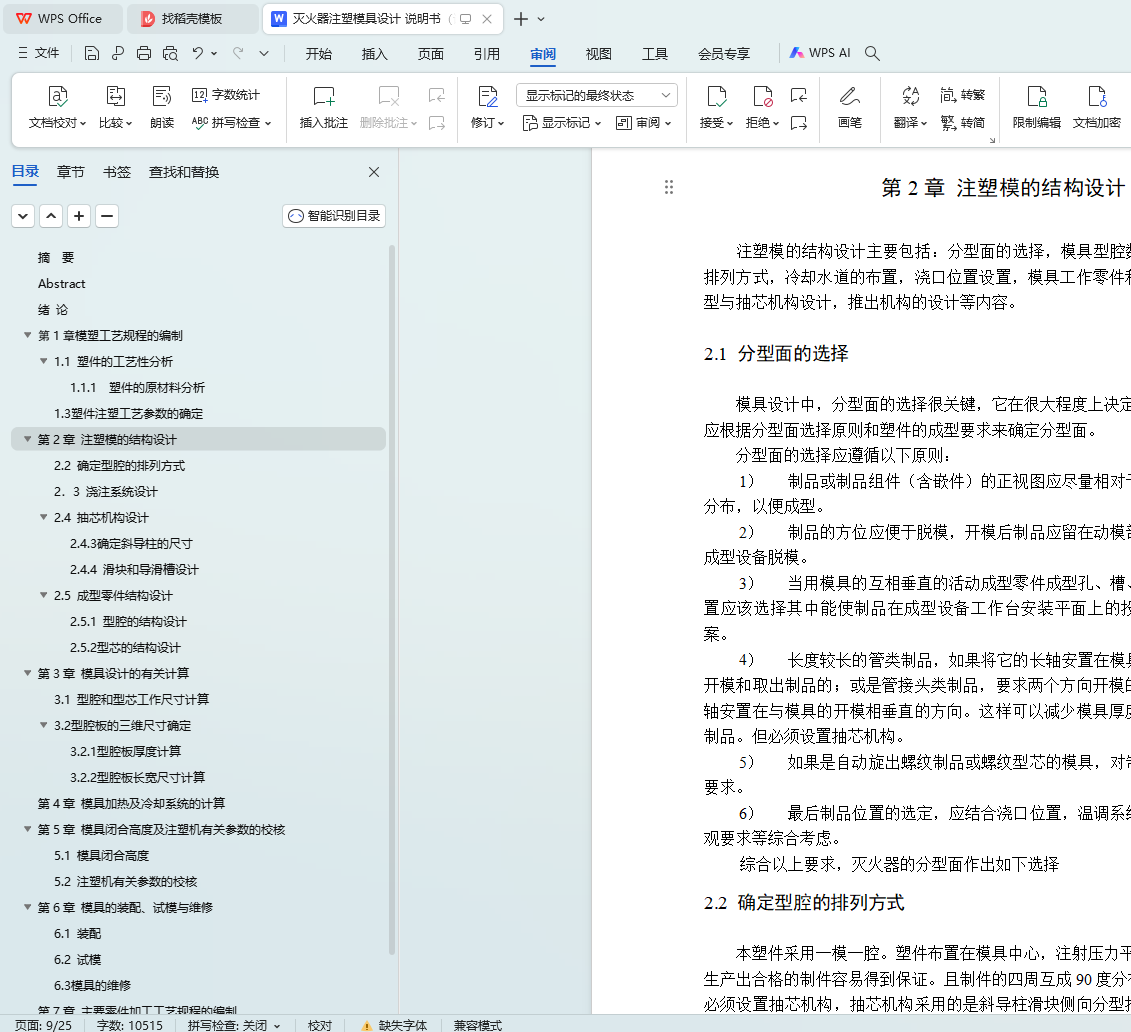

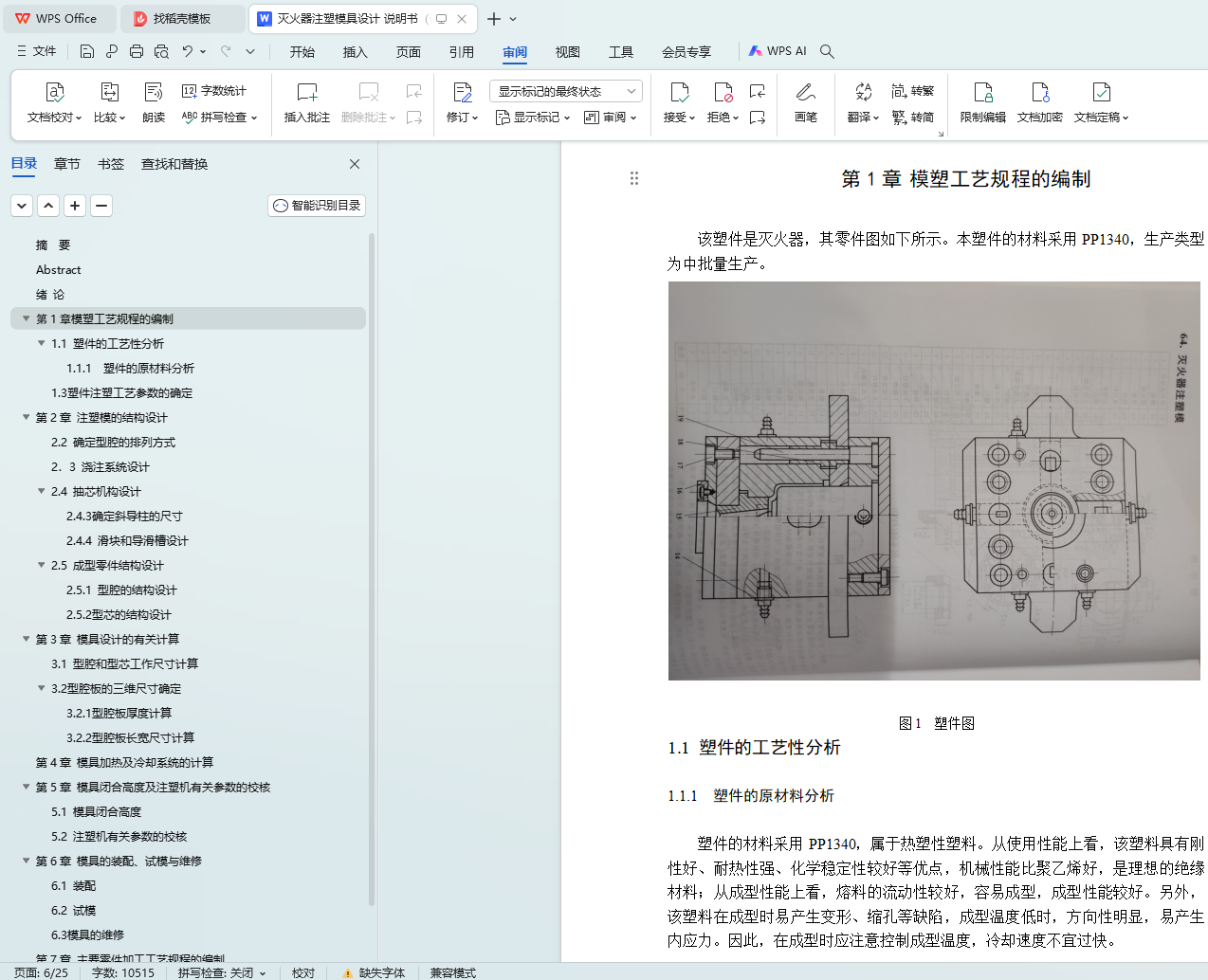

本文旨在设计一套完整的灭火器注塑模具,以满足实际生产需求。在设计过程中,重点考虑了模具的制造、安装、调试和维护的便利性。通过深入分析,确定了最佳的分模面,并合理构建了型腔,确保了注塑件的质量和精度。同时,优化了浇注系统,确保塑料流动均匀,减少缺陷的产生。顶出系统也经过精心设计,以实现平稳的脱模操作。此外,为了有效控制模具温度,设计了高效的冷却系统。对于复杂的分型和抽芯机构,本文也进行了深入研究,并提出了可行的解决方案。最终,根据制图规范,绘制了完整的二维零件图和装配图,并制作了对应的三维图,为模具的制造和安装提供了详细的指导。通过本次设计,不仅提高了模具的实用性和可靠性,也为类似产品的模具设计提供了有益的参考。

关键词:注塑模具;灭火器;分模面;浇注系统;顶出系统

Abstract

This paper aims to design a complete set of fire extinguisher injection mold to meet the actual production needs. In the design process, the convenience of mold manufacturing, installation, commissioning and maintenance is mainly considered. Through in-depth analysis, determine the best mold surface, and the cavity constructed to ensure the quality and precision of injection parts. At the same time, the pouring system is optimized to ensure uniform plastic flow and reduce the generation of defects. The top out system is also carefully designed to achieve smooth release operation. Moreover, an efficient cooling system is designed to effectively control the mold temperature. For the complex typing and core extraction institutions, this paper also conducts in-depth research, and proposes feasible solutions. Finally, according to the drawing specification, the complete 2 D part map and assembly map were drawn, and the corresponding 3 D map was made, which provided detailed guidance for the manufacture and installation of the mold. Through this design, not only improve the practicability and reliability of the mold, but also provides a useful reference for the mold design of similar products.

Key words: injection molding; fire extinguisher; molding surface; pouring system and jacking system

目 录