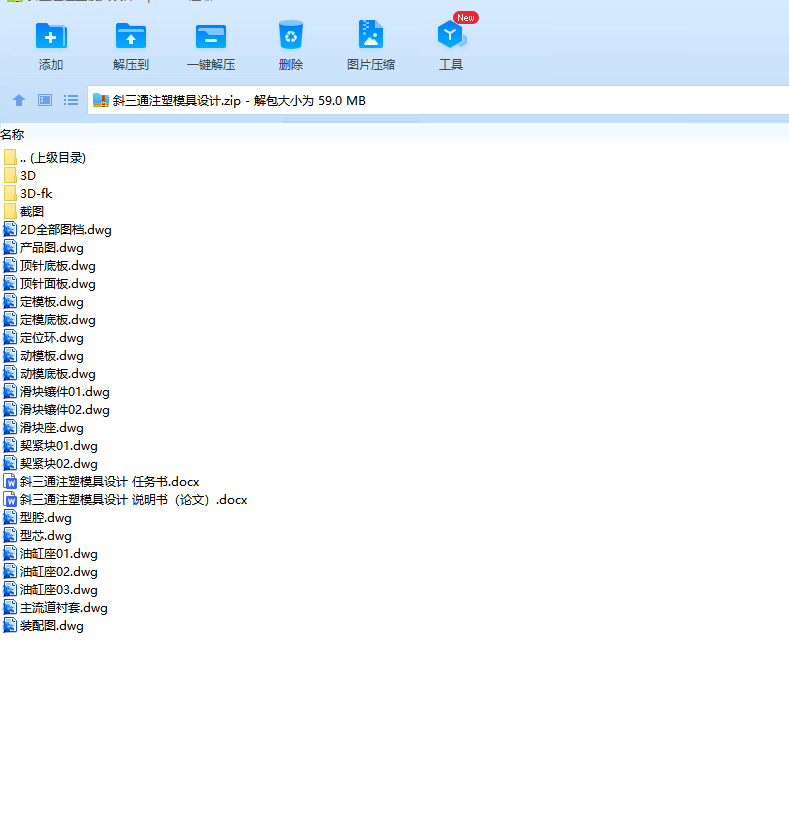

斜三通注塑模具设计 说明书(论文)+任务书+CAD图纸+UG三维图

摘 要

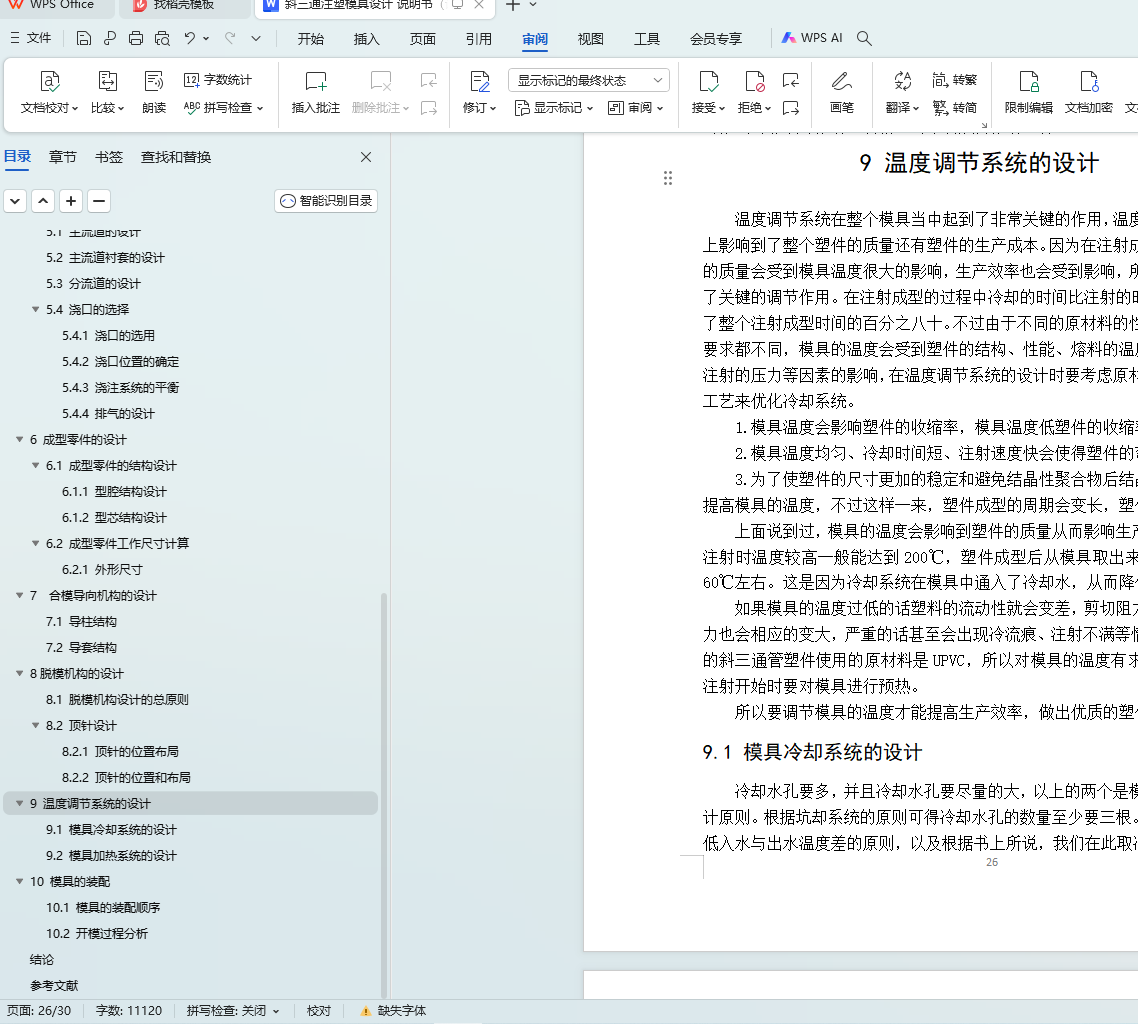

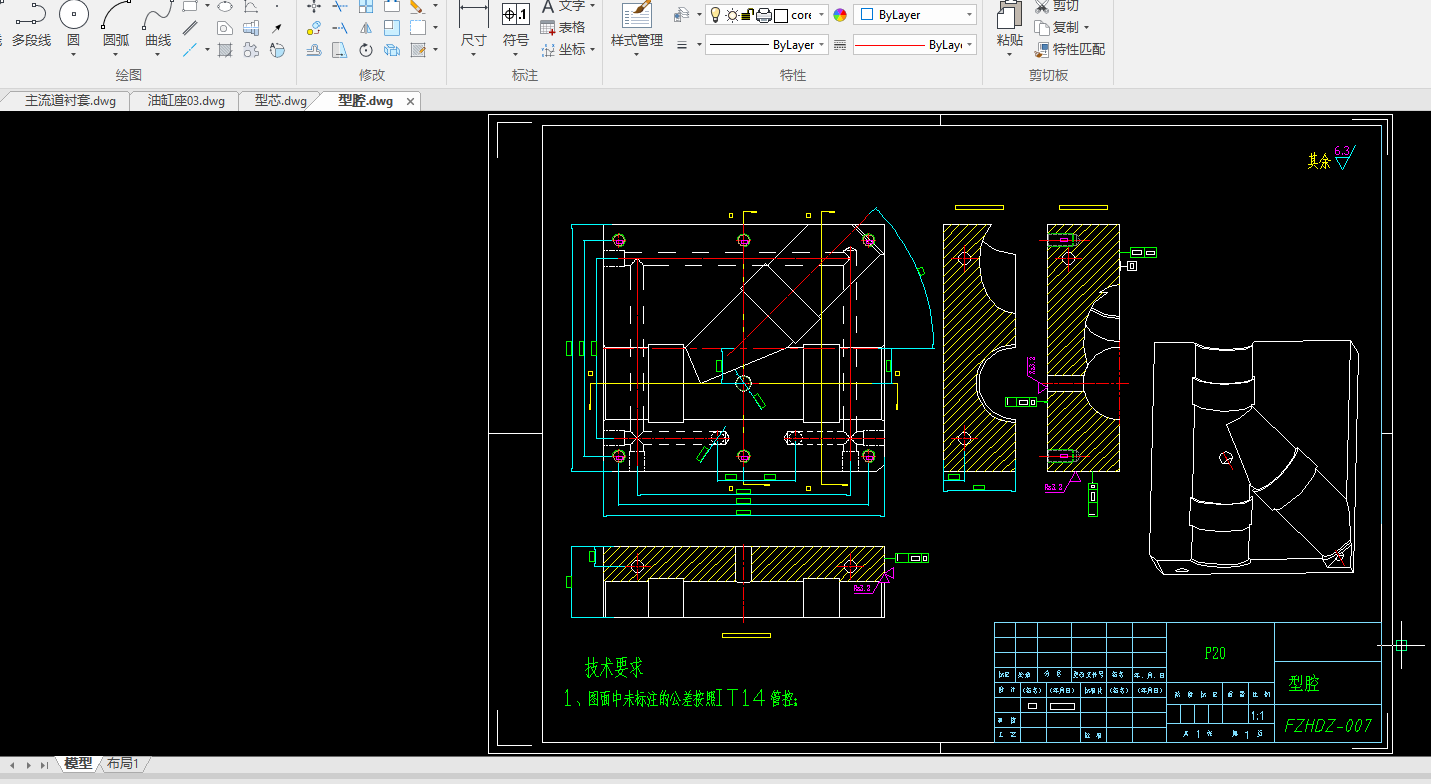

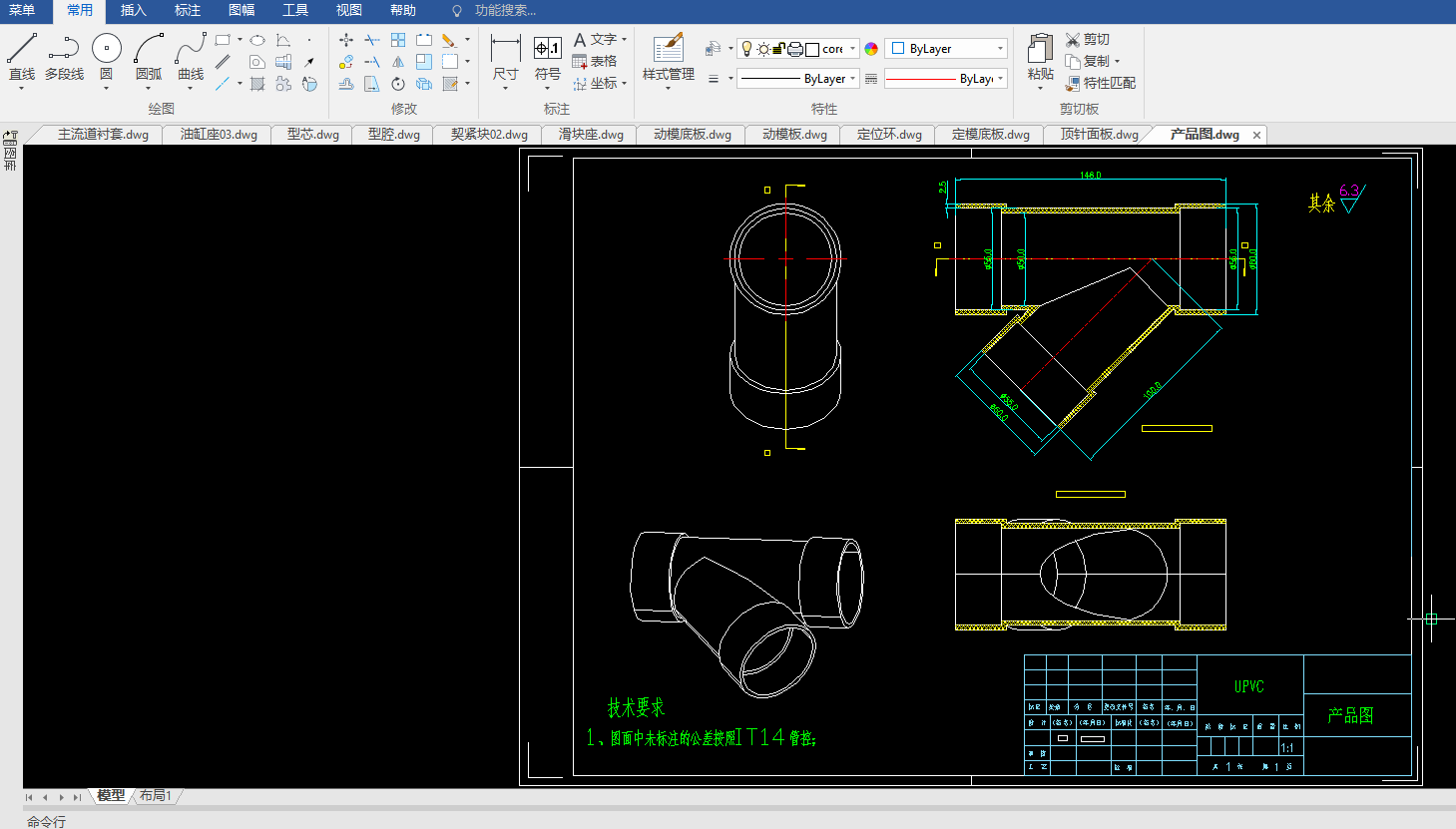

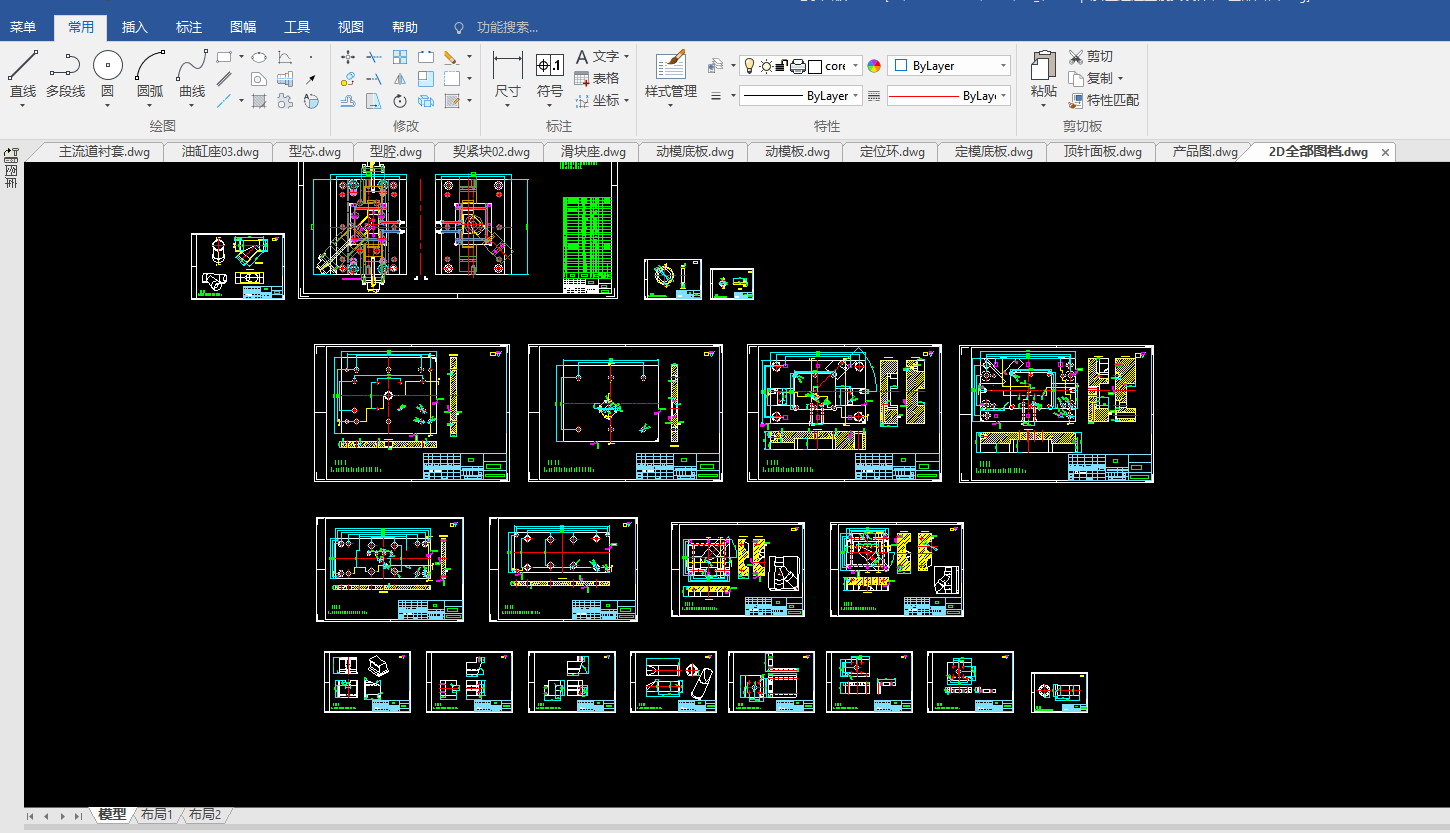

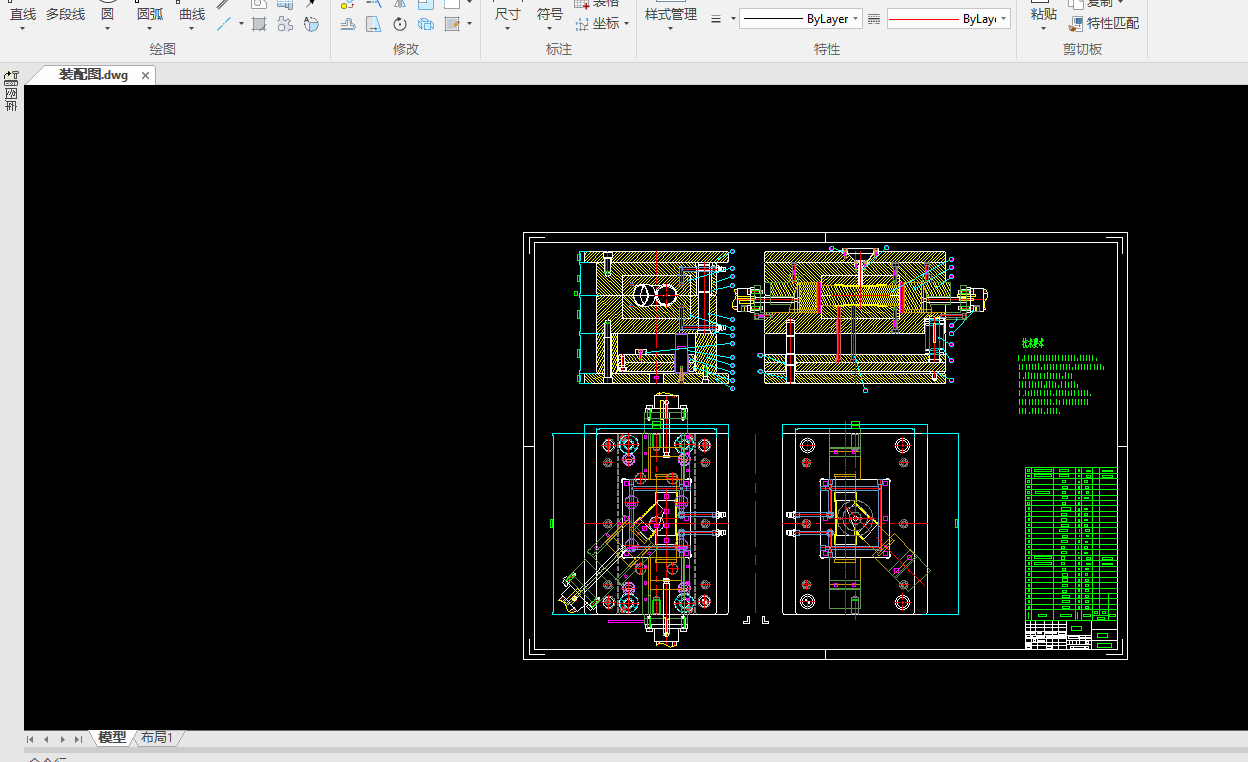

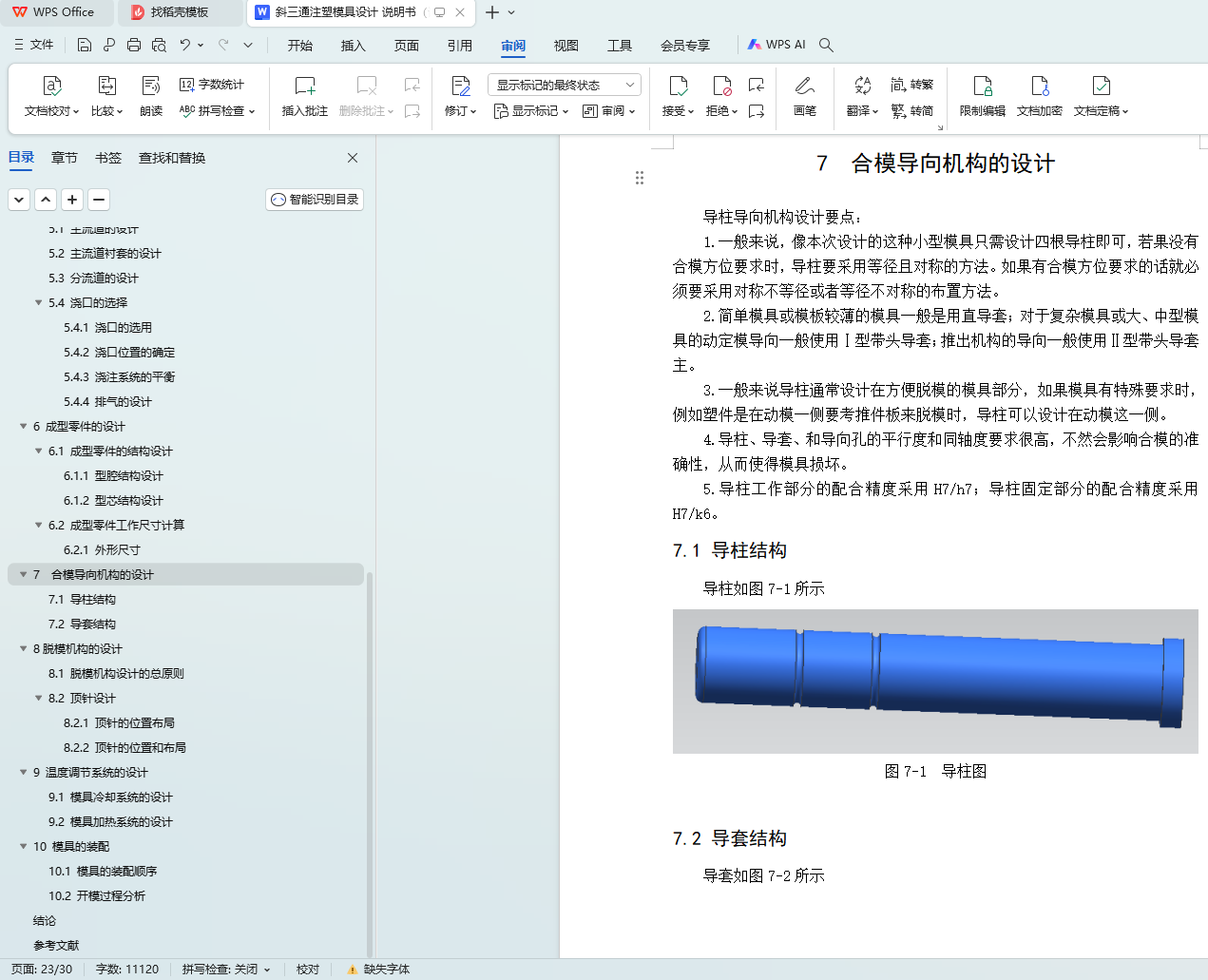

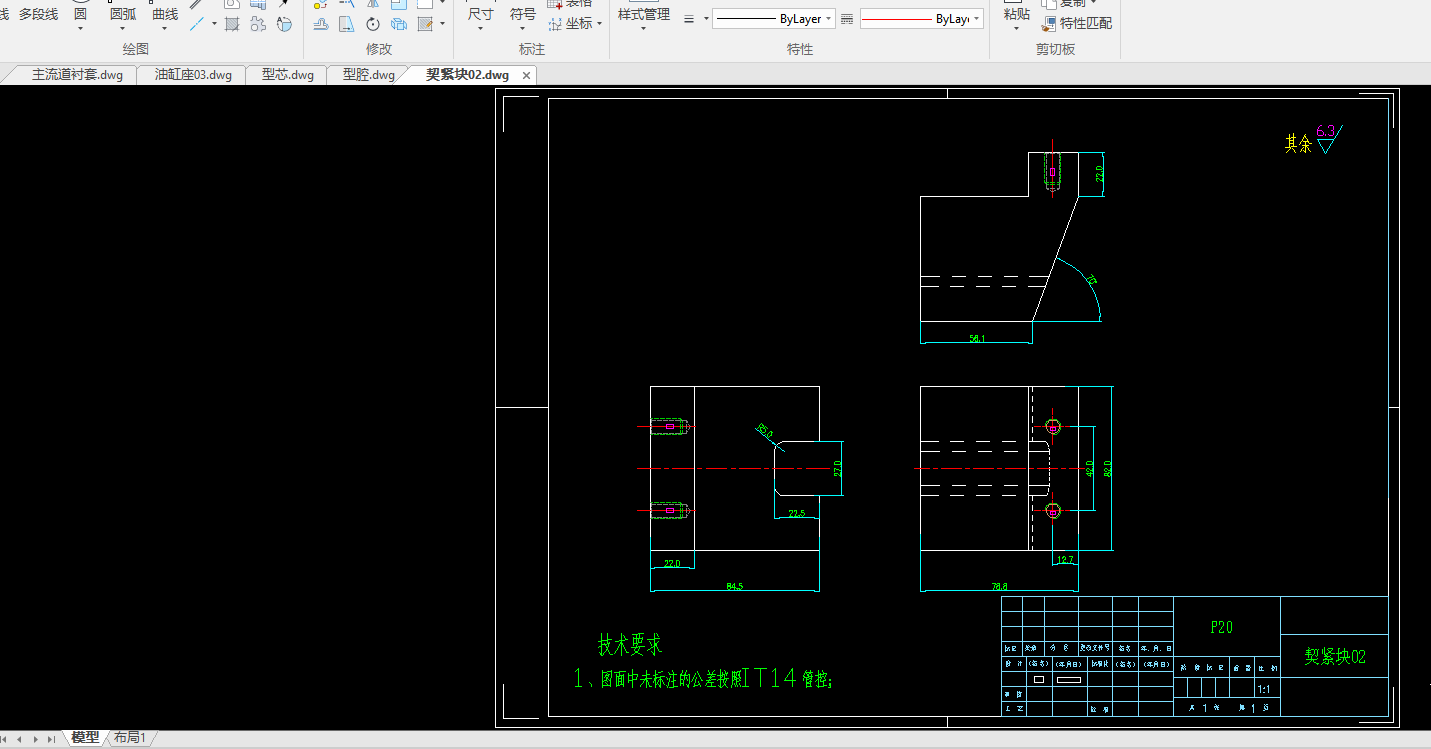

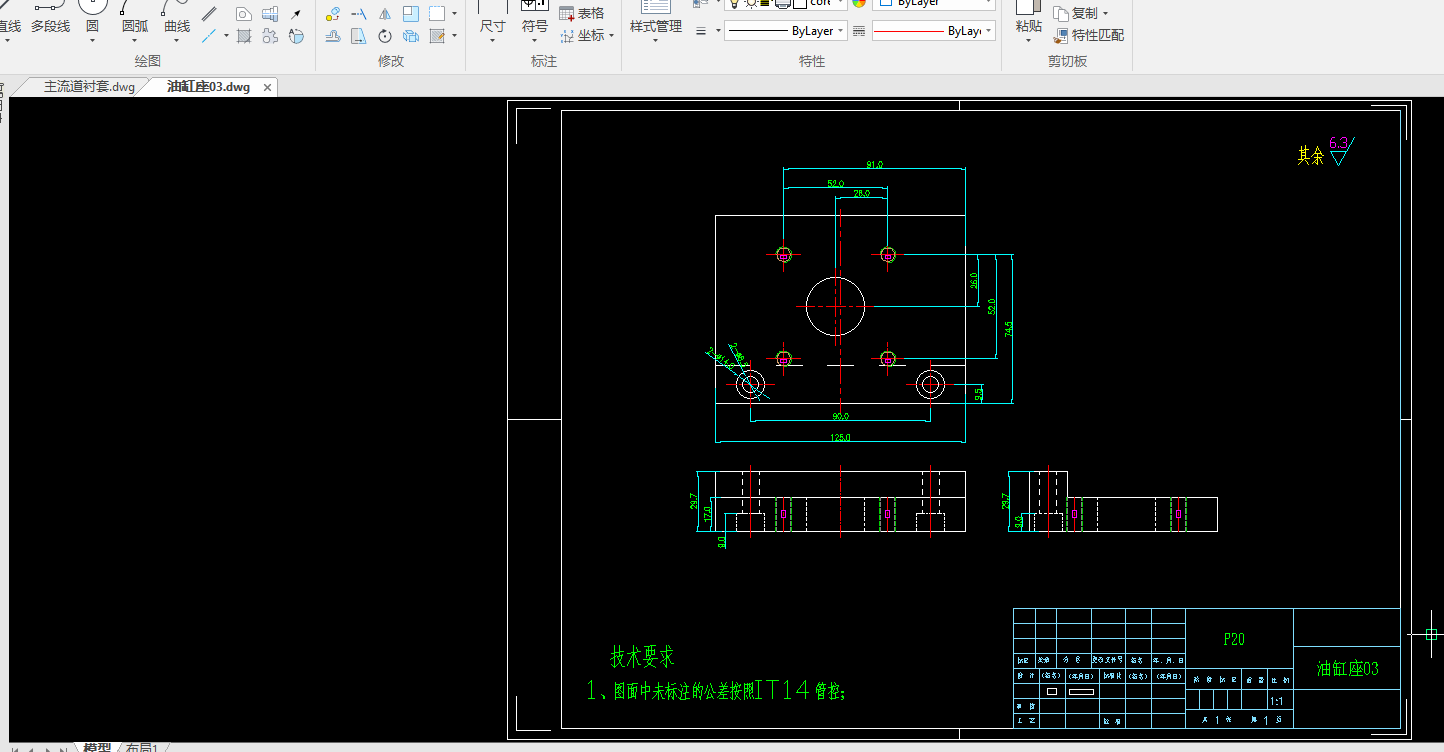

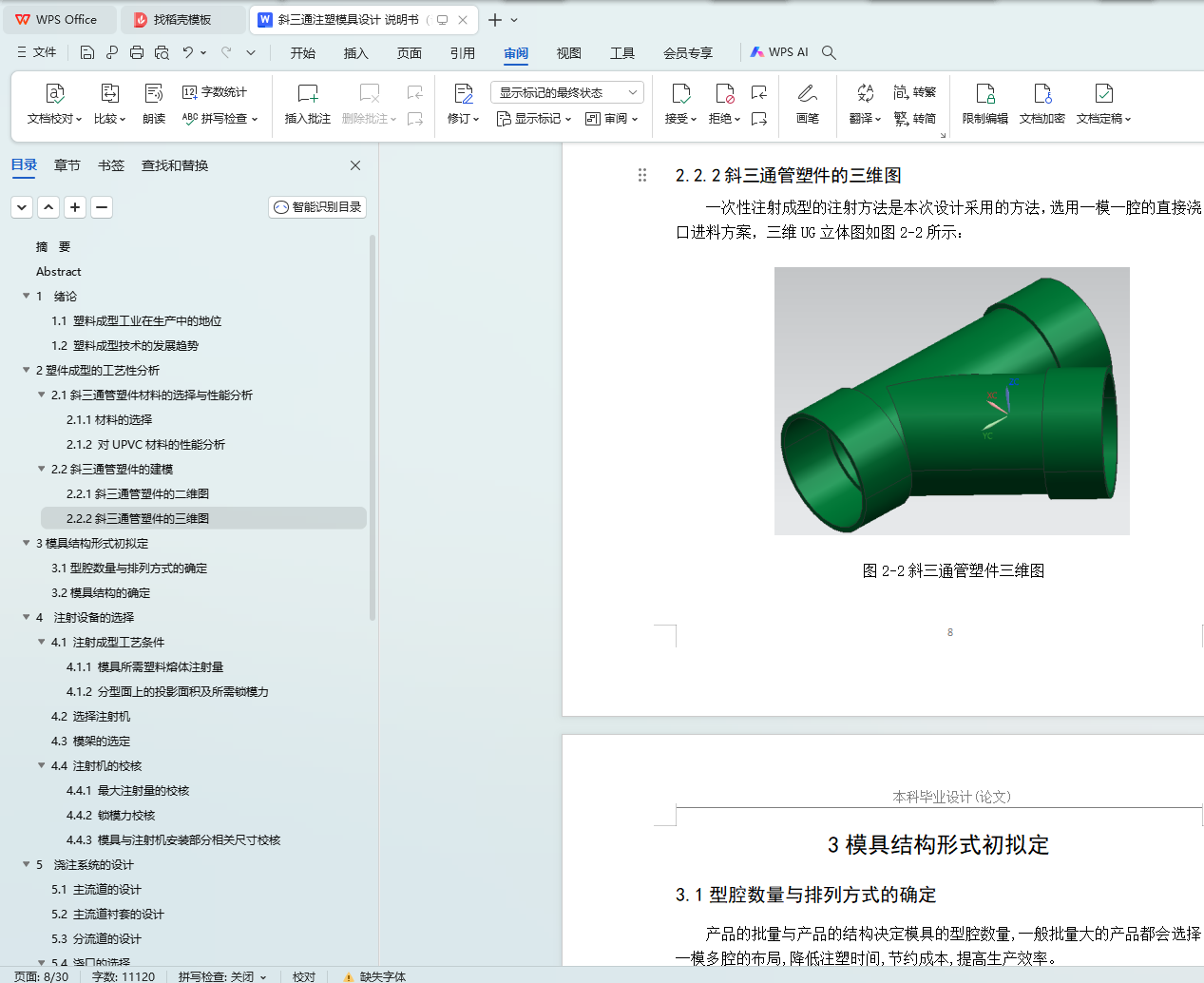

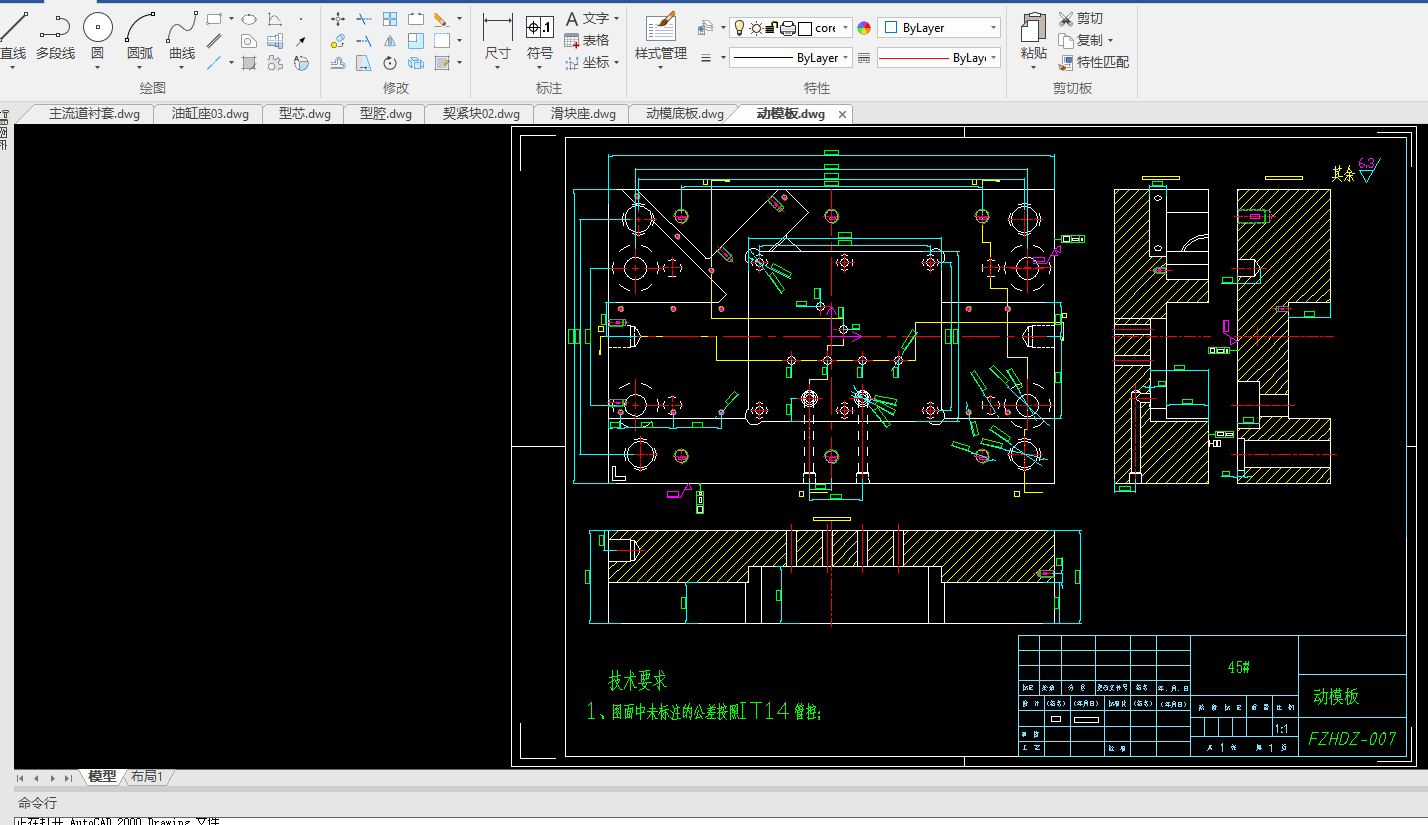

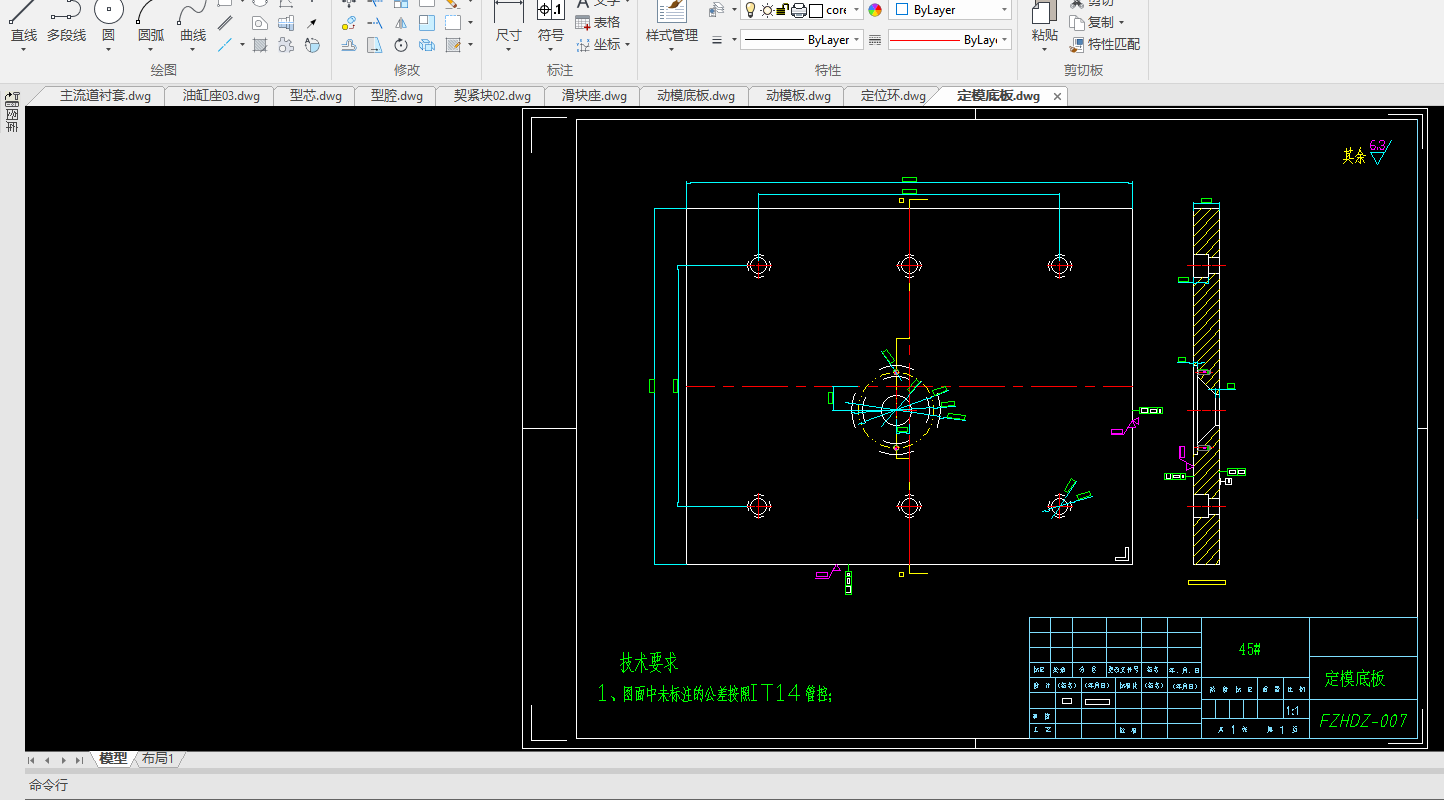

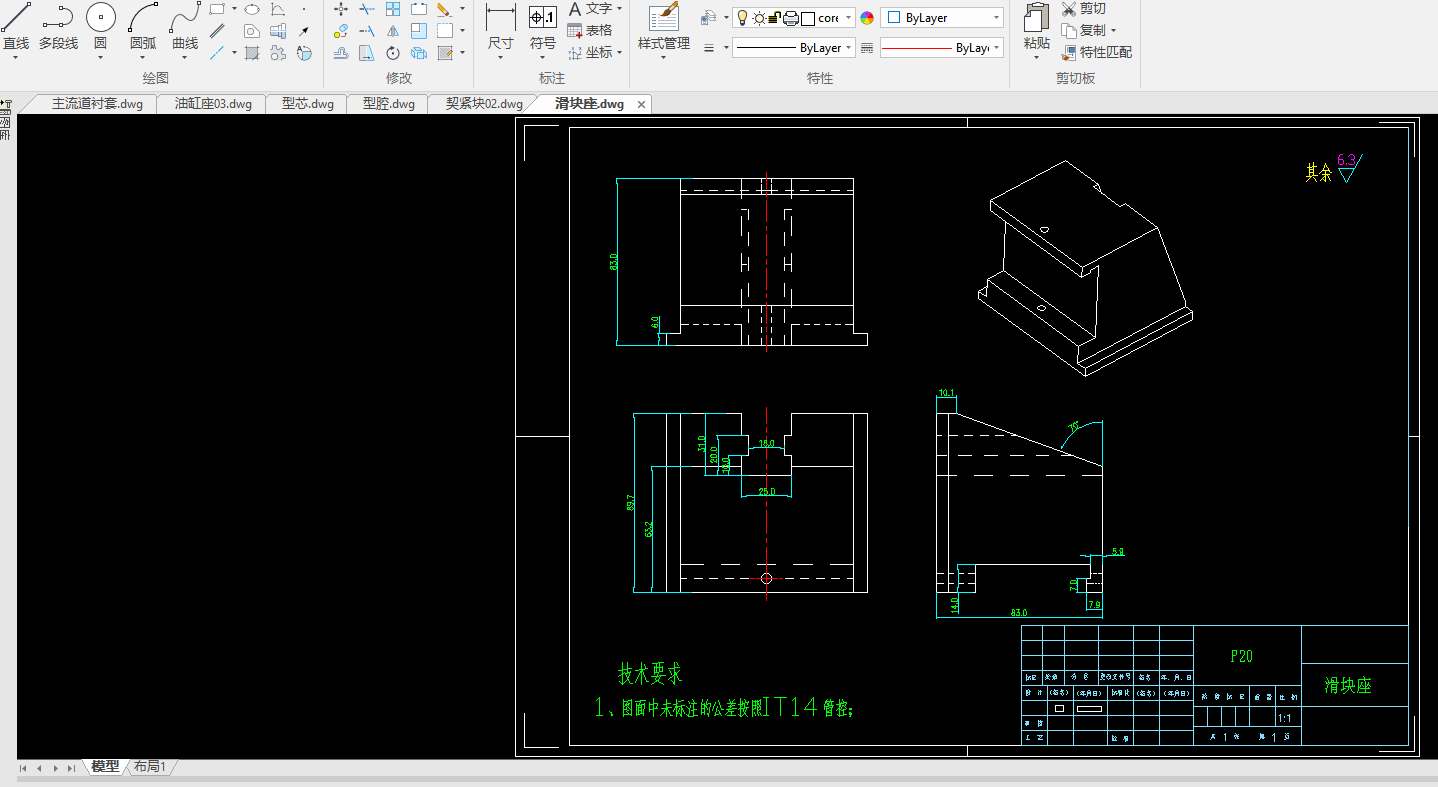

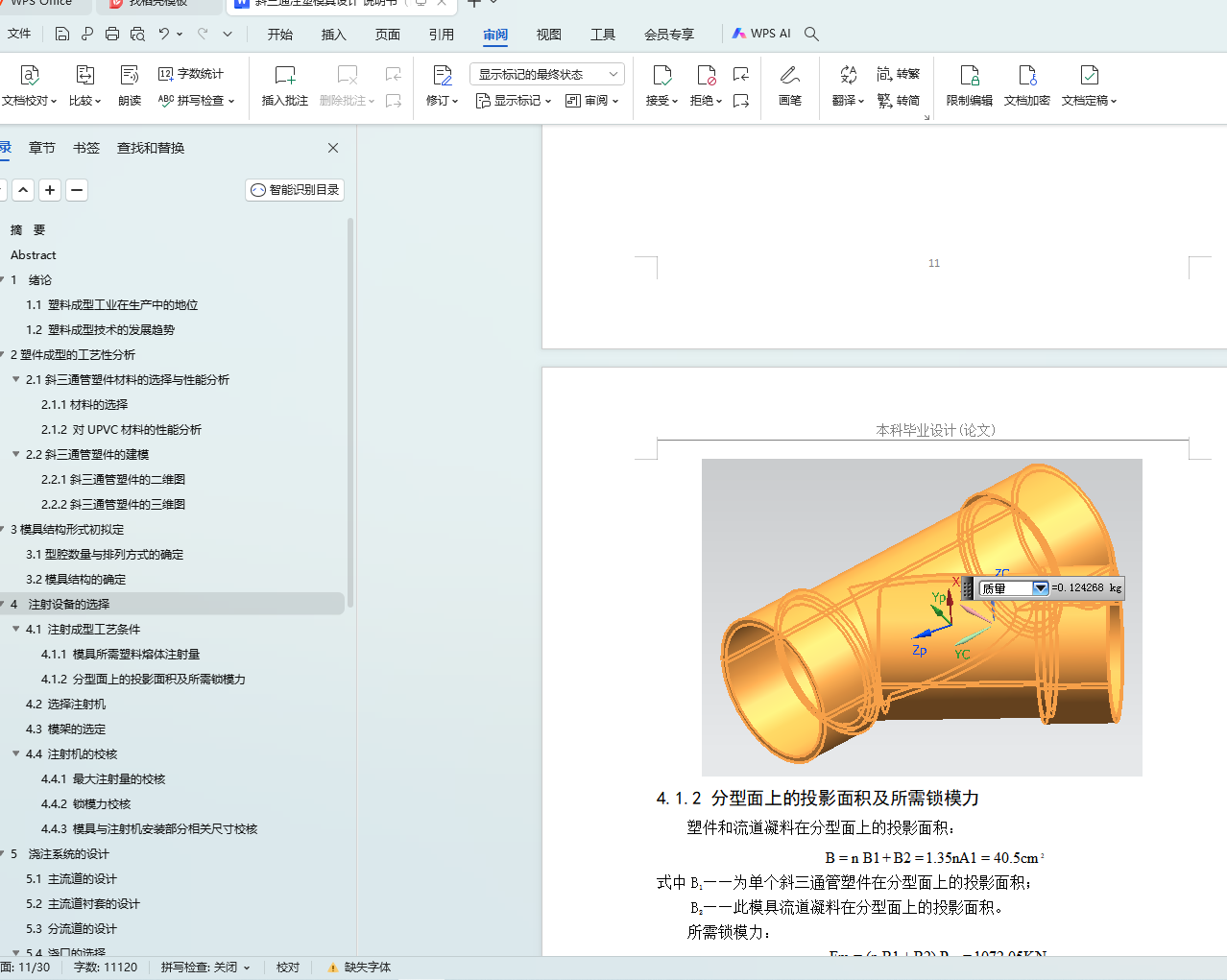

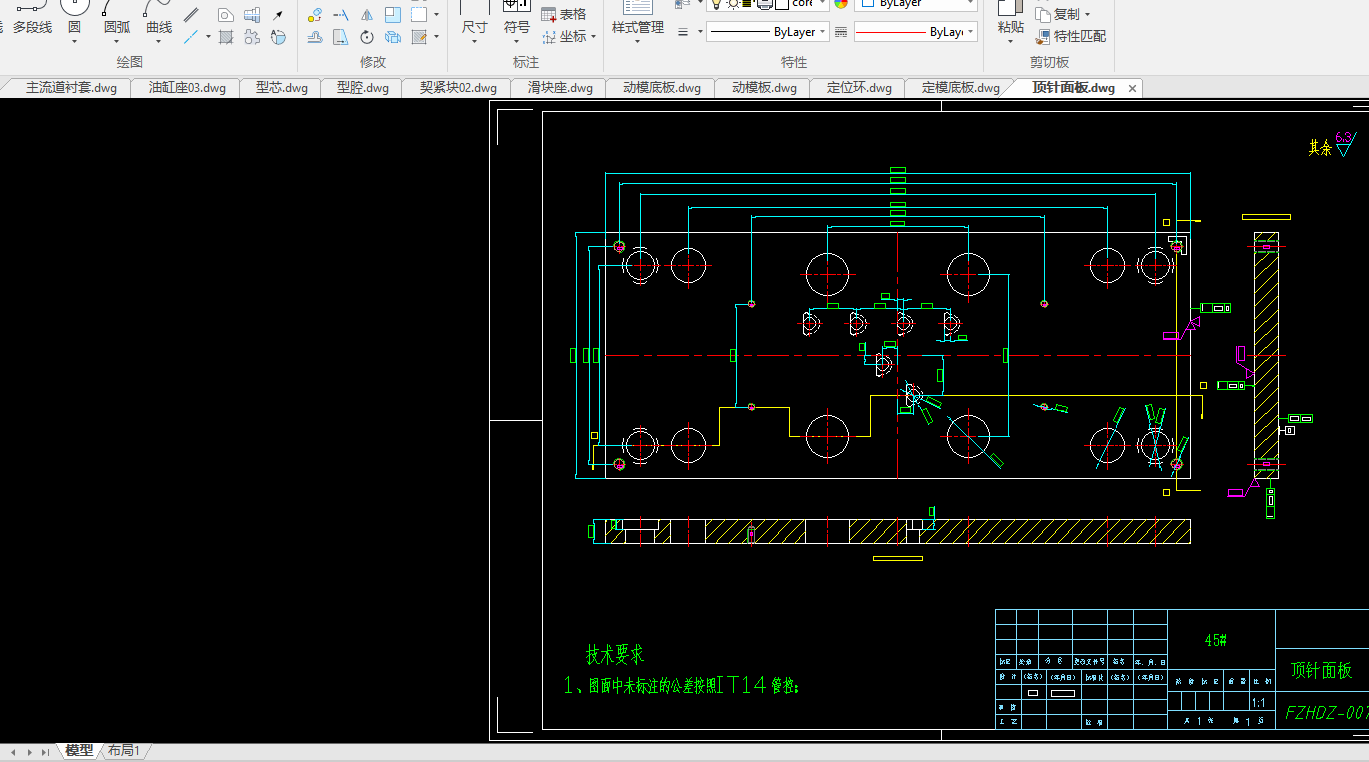

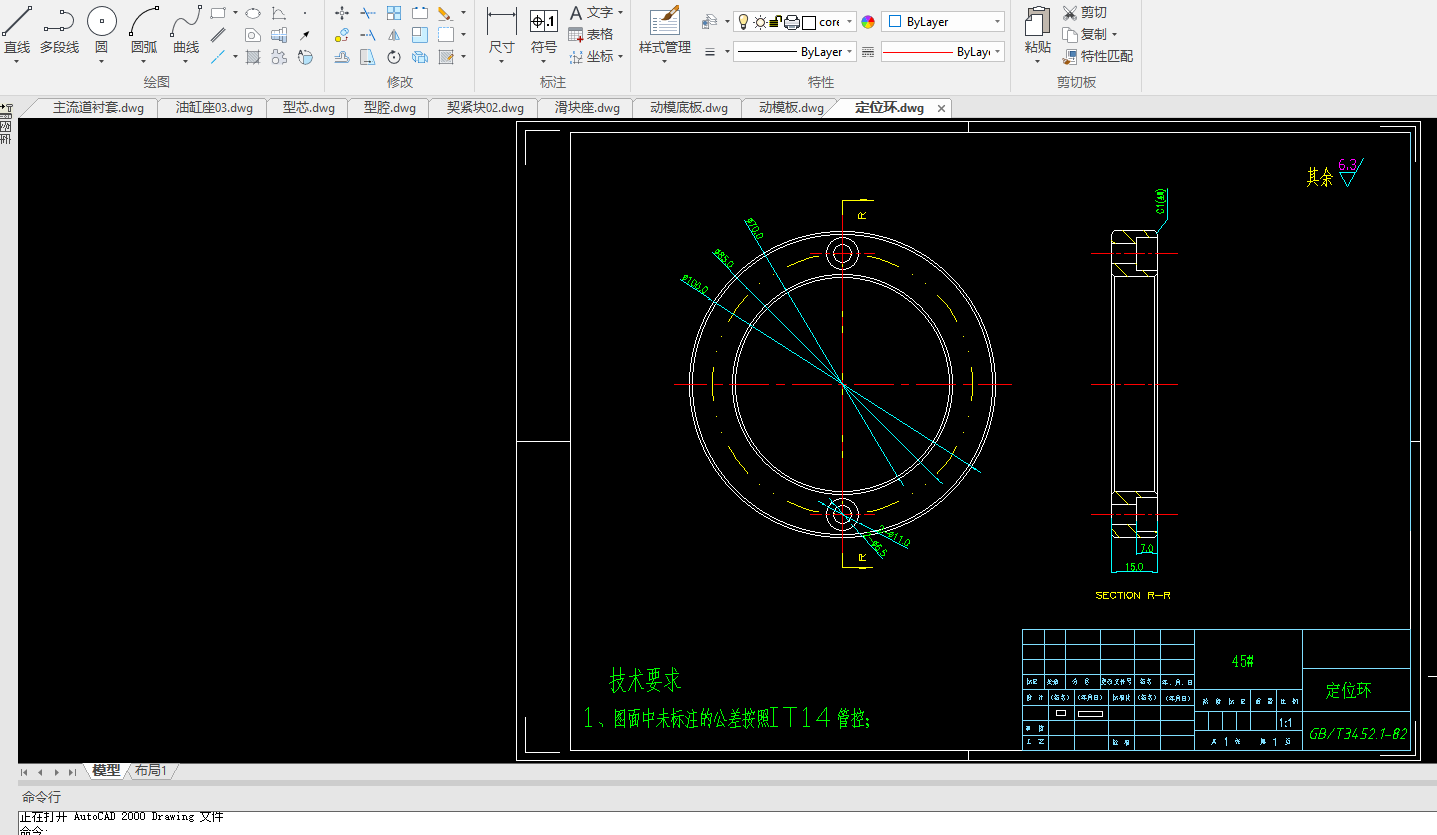

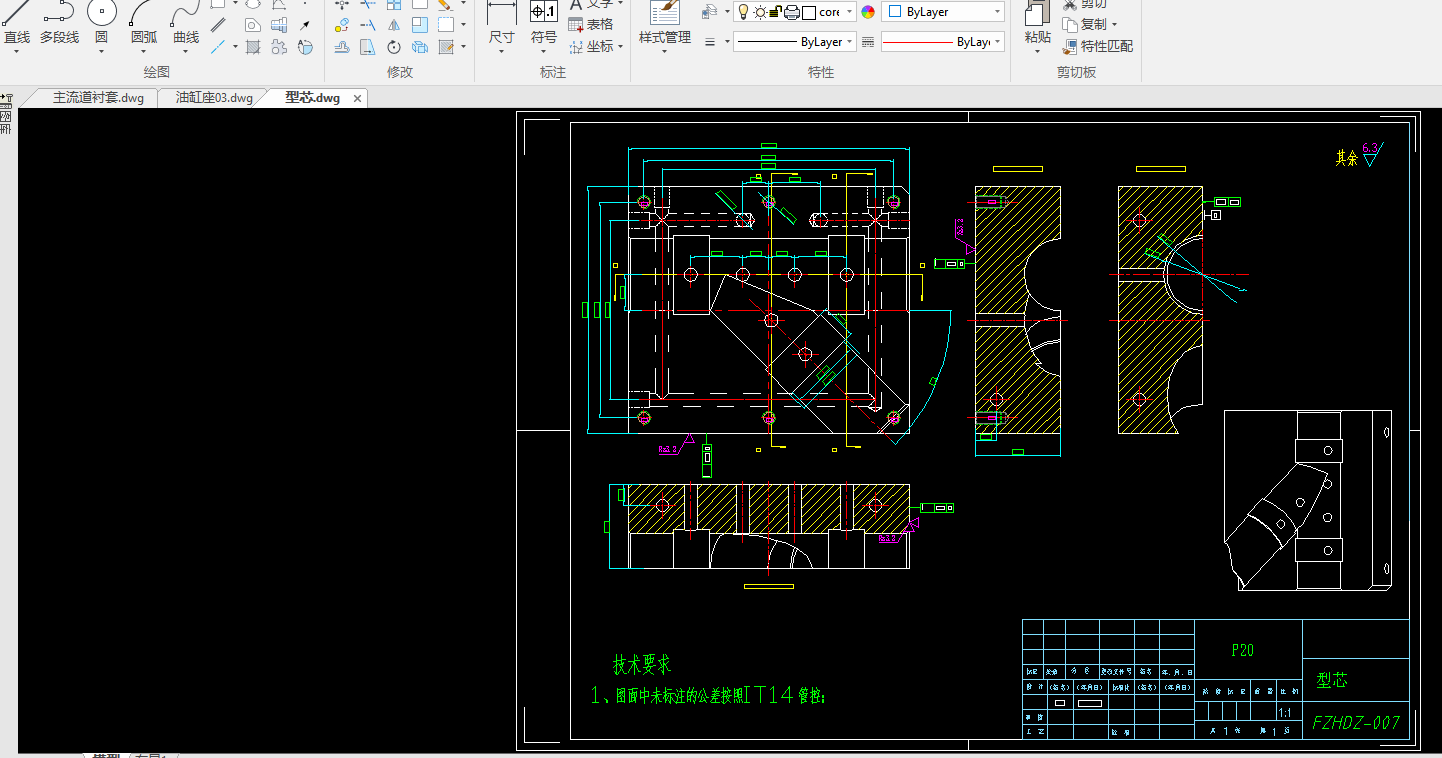

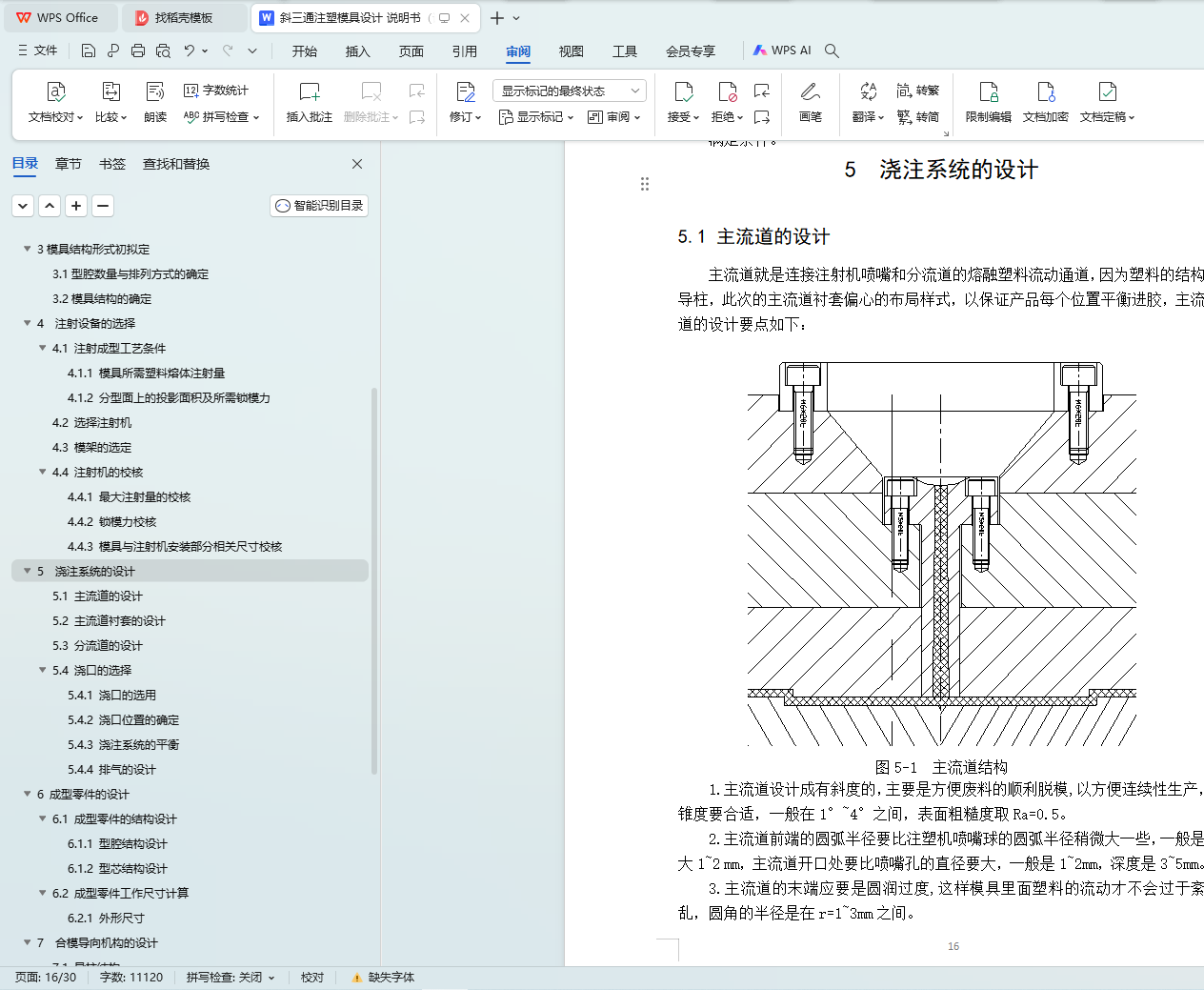

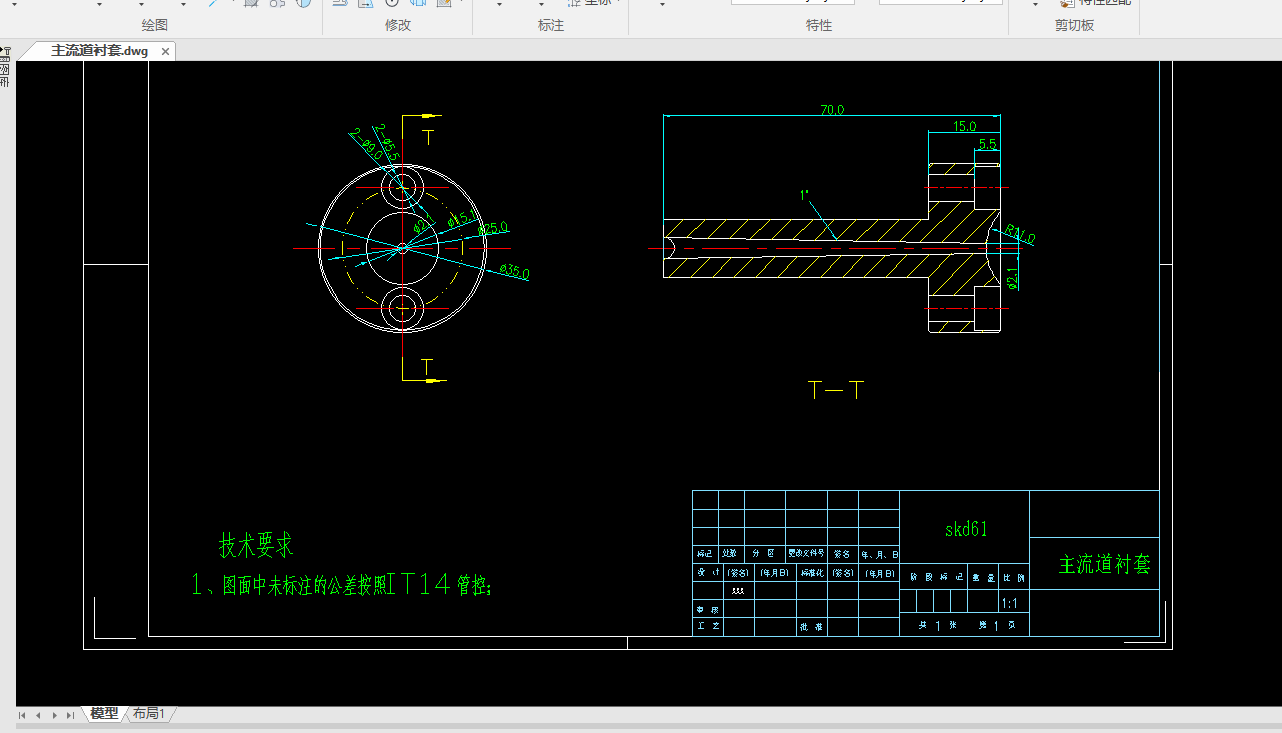

本文旨在设计一套完整的斜三通注塑模具,以满足大批量生产的需求。在设计过程中,我们综合考虑了模具的制造、安装、调试与维护的便捷性,并精心选择了最佳分模面、型腔构成、浇注系统、顶出系统、冷却系统以及分型和抽芯机构等关键要素。通过对斜三通管塑件的工艺可行性分析,我们确定了合适的注塑机和模架,进而精确计算并确定了各零件的尺寸。利用UG软件绘制了精确的三维图,并采用CAD软件制作了符合制图规范的二维零件图和装配图。斜三通管塑件具有重量轻、强度高和耐腐蚀性好等特点,而注塑成型法则以其高效、快速、自动化和复杂形状成型能力强的优势,成为实现这一零件大批量生产的理想选择。本文详细阐述了模具设计的全过程,为类似产品的模具设计提供了有益的参考。

关键词:斜三通注塑模具;注塑成型;模具设计;UG;CAD;

Abstract

This paper aims to design a complete set of oblique injection molds to meet the demand of mass production. In the design process, we comprehensively considered the convenience of manufacturing, installation, debugging and maintenance of the mold, and carefully selected the key elements such as the best mold surface, cavity composition, pouring system, jacking system, cooling system, classification and core extraction mechanism and so on. Through the process feasibility analysis of pipe, we determine the appropriate injection molding machine and frame, and then calculate and determine the size of each part. We used the UG software, and made the parts and assembly drawings with the CAD software. The oblique tee tube plastic parts have the characteristics of light weight, high strength and good corrosion resistance, and the injection molding method with its high efficiency, fast, automatic and complex shape forming ability advantages, become the ideal choice to achieve the mass production of this part. This paper expounds the whole process of mold design in detail, which provides a useful reference for the mold design of similar products.

Key words: oblique injection molding; injection molding; mold design; UG; CAD;

目录