汽车车门外板冲压模具设计 说明书(论文)+任务书+开题报告+文献综述+外文翻译及原文+CAD图纸

摘 要

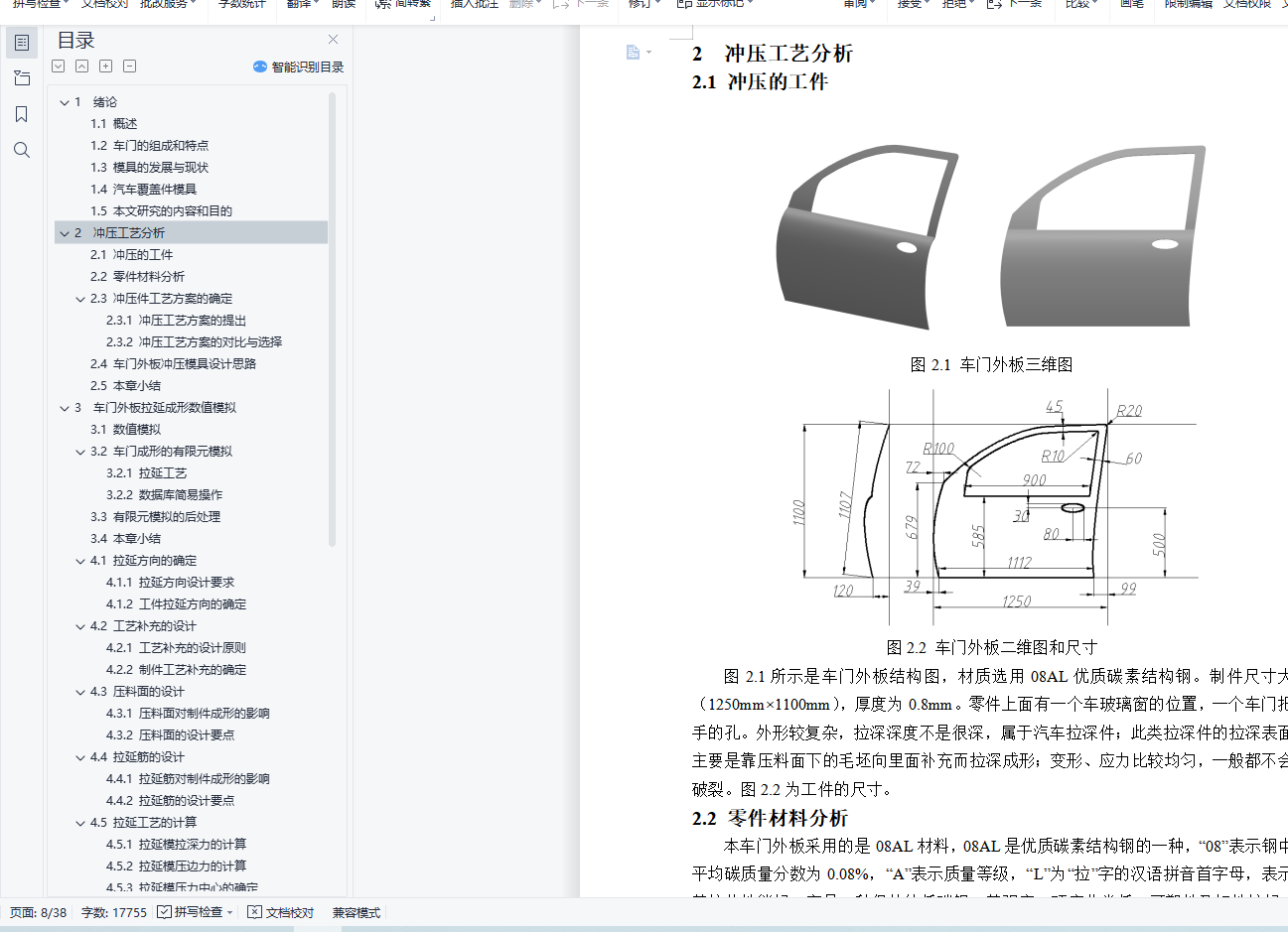

本次设计的内容是某轿车前车门外板的冲压模具,分析了汽车覆盖件及其冲压模具的特点及要求。汽车覆盖件的尺寸大结构属于复杂的曲面结构,零件表面的质量要求高,因此对其模具的设计也比较复杂。

该零件的数学模型为由曲面构成的非参数化特征,首先利用UG软件绘制该零件的三维造型,再对其成形特点和成形工艺进行分析,为了得到合格的零件产品,必须先进行生产方案的分析与确定。再利用Dynaform软件进行数值模拟分析,借助软件对其拉深方向、工艺补充、坯料尺寸、零件的成形极限、厚度变化情况和拉延力等进行分析计算,最后是对其成形模具进行设计。

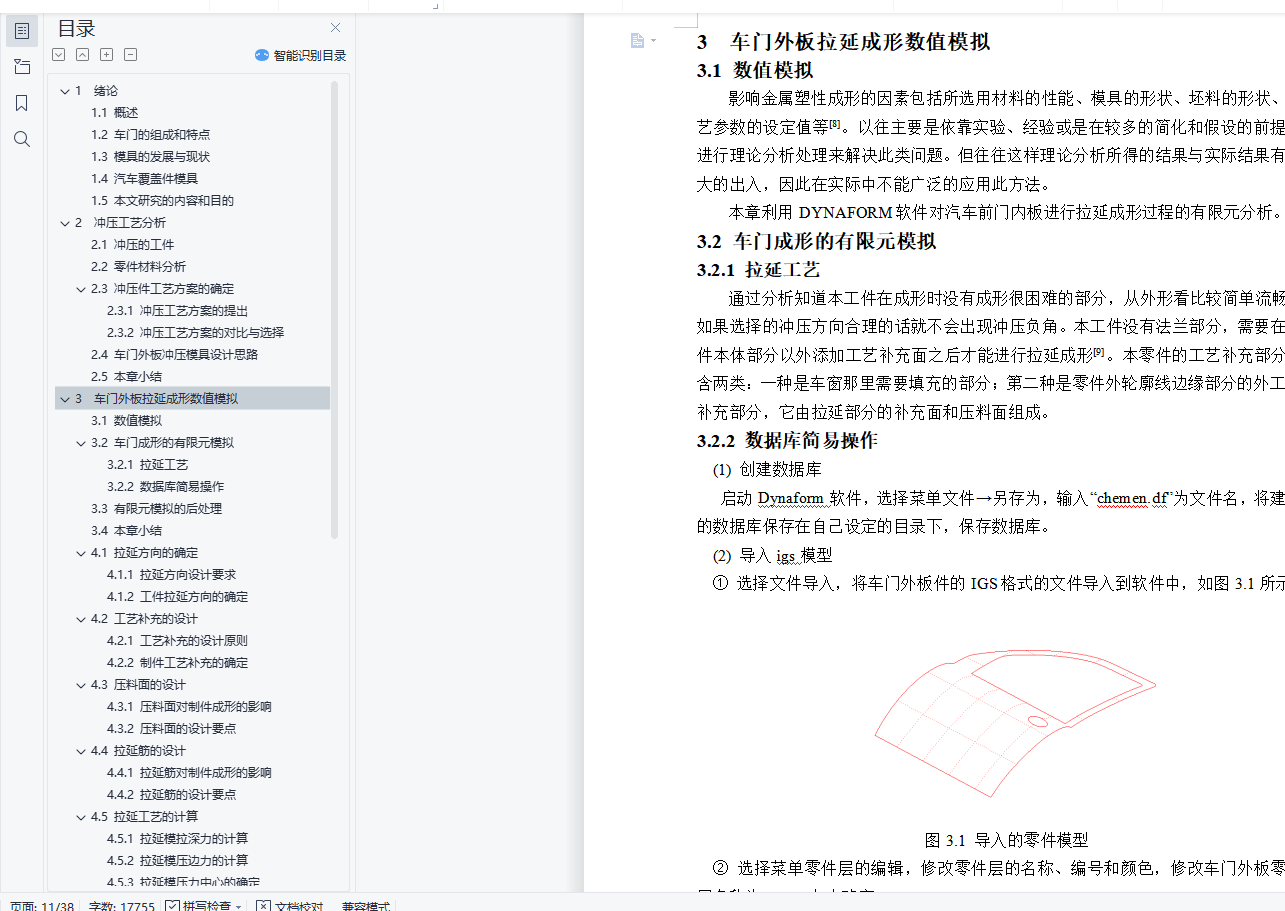

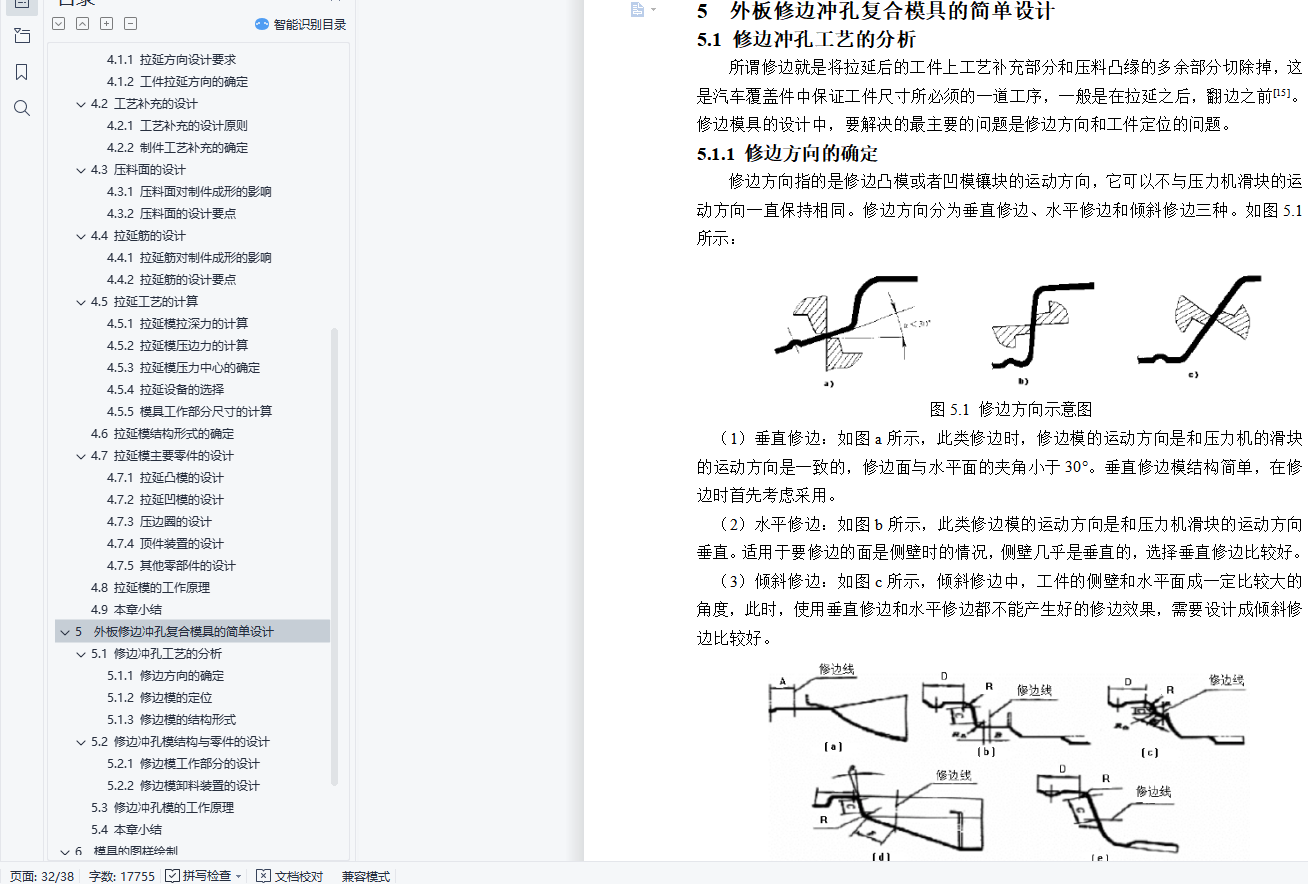

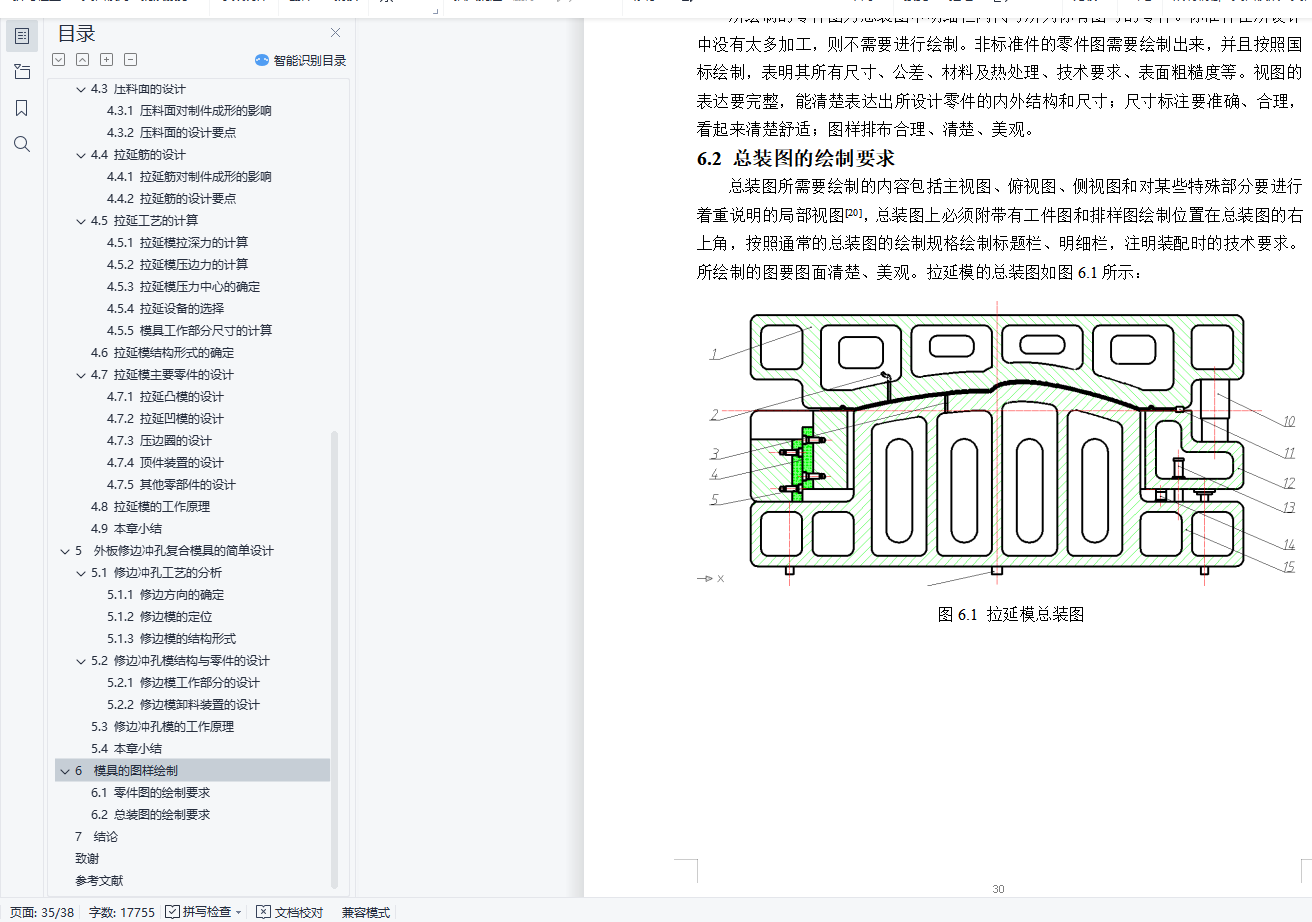

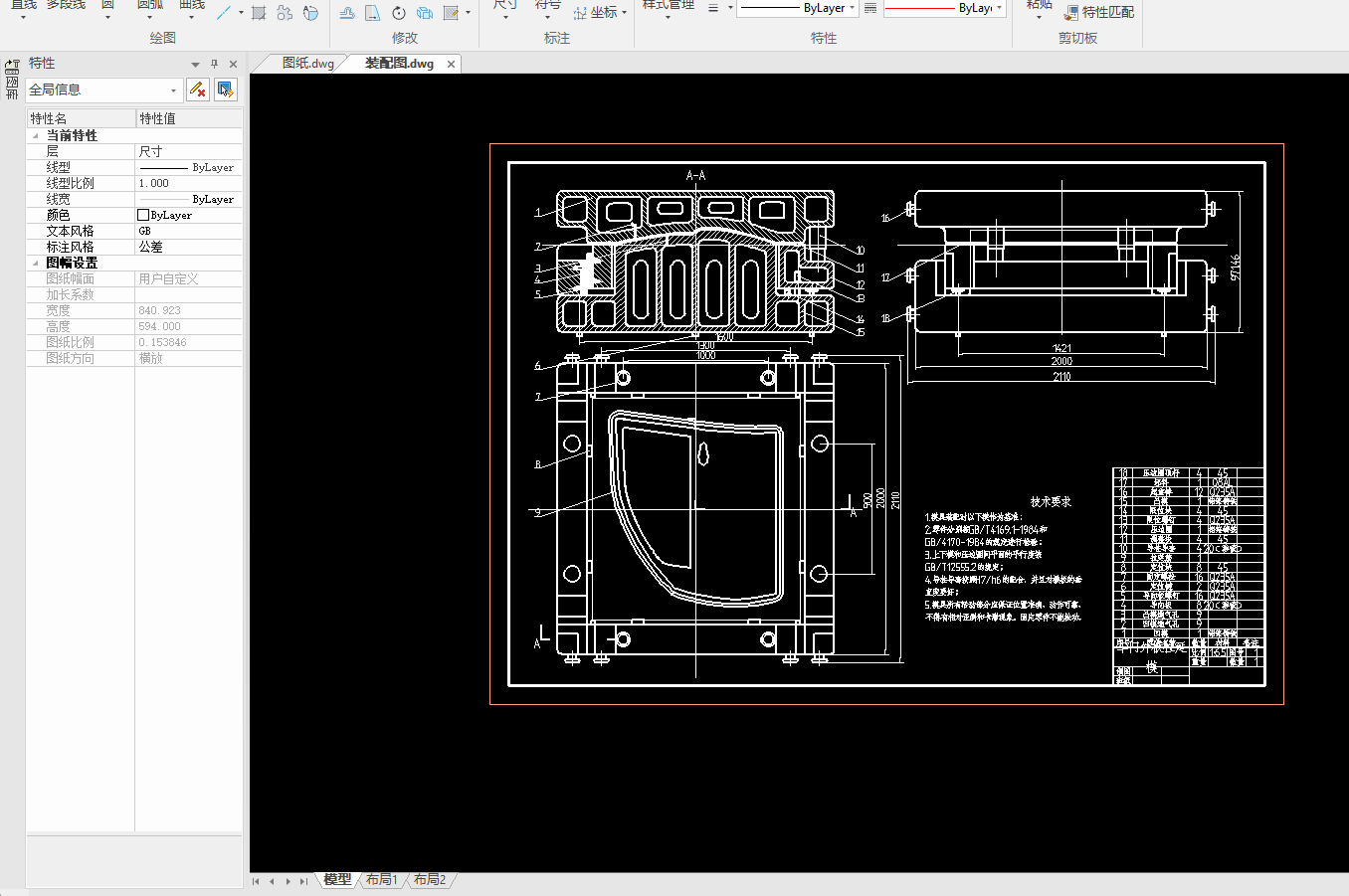

拉延模的设计是本设计的重点,包括冲压方向的确定、内外工艺补充面、压料面的确定、拉延筋的设计、工艺计算等,重点对拉延凸模、凹模、压边圈进行设计,还有对顶件装置、导向装置、合模限位装置、起吊装置和通气孔等进行设计。工件在拉延成形之后需要进行修边和冲孔,在这里以拉延模为基础对修边冲孔模进行简单的设计和说明,完成工件的冲压成形。最后绘制了拉延模具的二维装配图和部分零件图。

关键词:车门外板;覆盖件;工艺分析;模具设计;UG

The design of car door panels stamping die

Abstract: The content is designed for a car before the car door panel stamping dies, analyzes and stamping automotive panel characteristics and requirements. Large size structure of an automobile covering parts are complex surface structure, high quality requirements of the part surface, so the design of their molds more complicated.

Mathematical model of the part of the grounds of non-parametric feature curved surface, the first use of UG software to draw three-dimensional modeling of the part, and then analyzed the characteristics shaping and forming processes, in order to get qualified parts products must be produced programs Analysis and determination. Reuse Dynaform numerical simulation analysis software, with the software to its drawing direction, forming limit addendum, blank size, part thickness changes and drawing force of analysis and calculation, and finally the design of its mold.

Drawing die design is the focus of this design, including stamping direction is determined, both inside and outside addendum, binder determination drawbead design, process calculation, focusing on drawing punch, die, blankholder ring design, as well as for top pieces of equipment, guides, clamping stopper, lifting device and the vent, etc. design. After forming the workpiece drawing needed trimming and punching, drawing die in here with the basis for trimming punching die design and simple instructions to complete the stamping workpiece shape. Finally, draw the two-dimensional drawing die assembly drawing and some parts Fig.

Key words:car door panels;cover;process pnalysis;mold design;UG

目 次