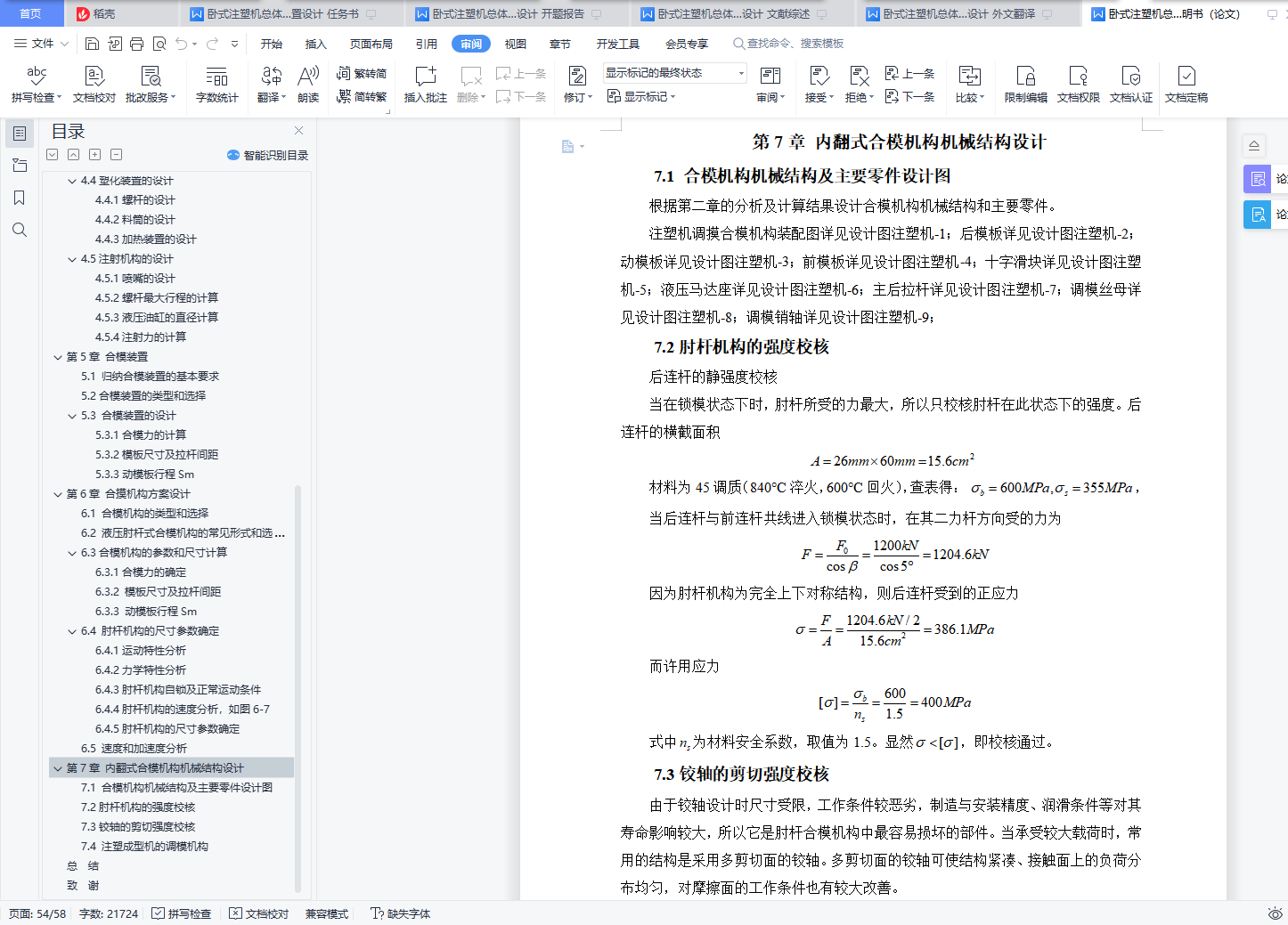

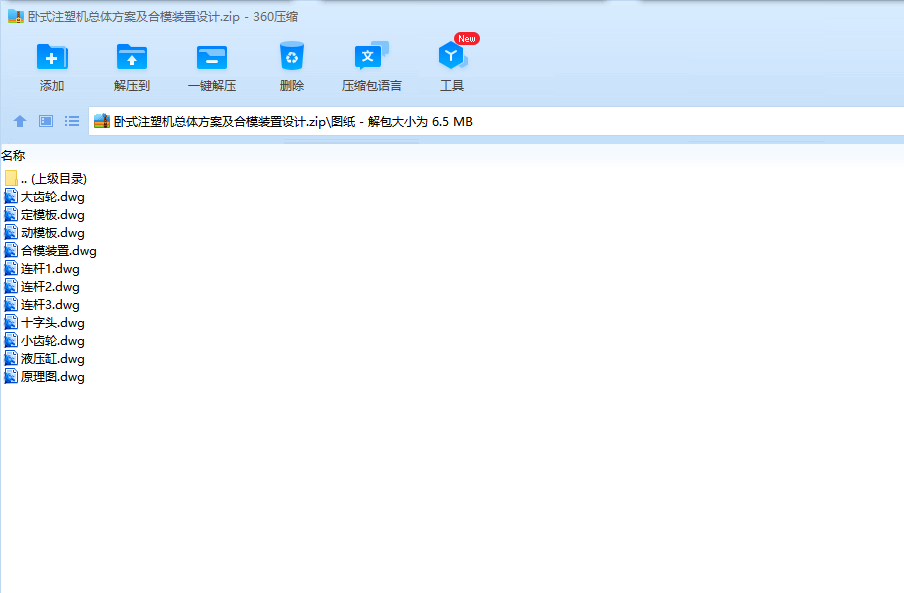

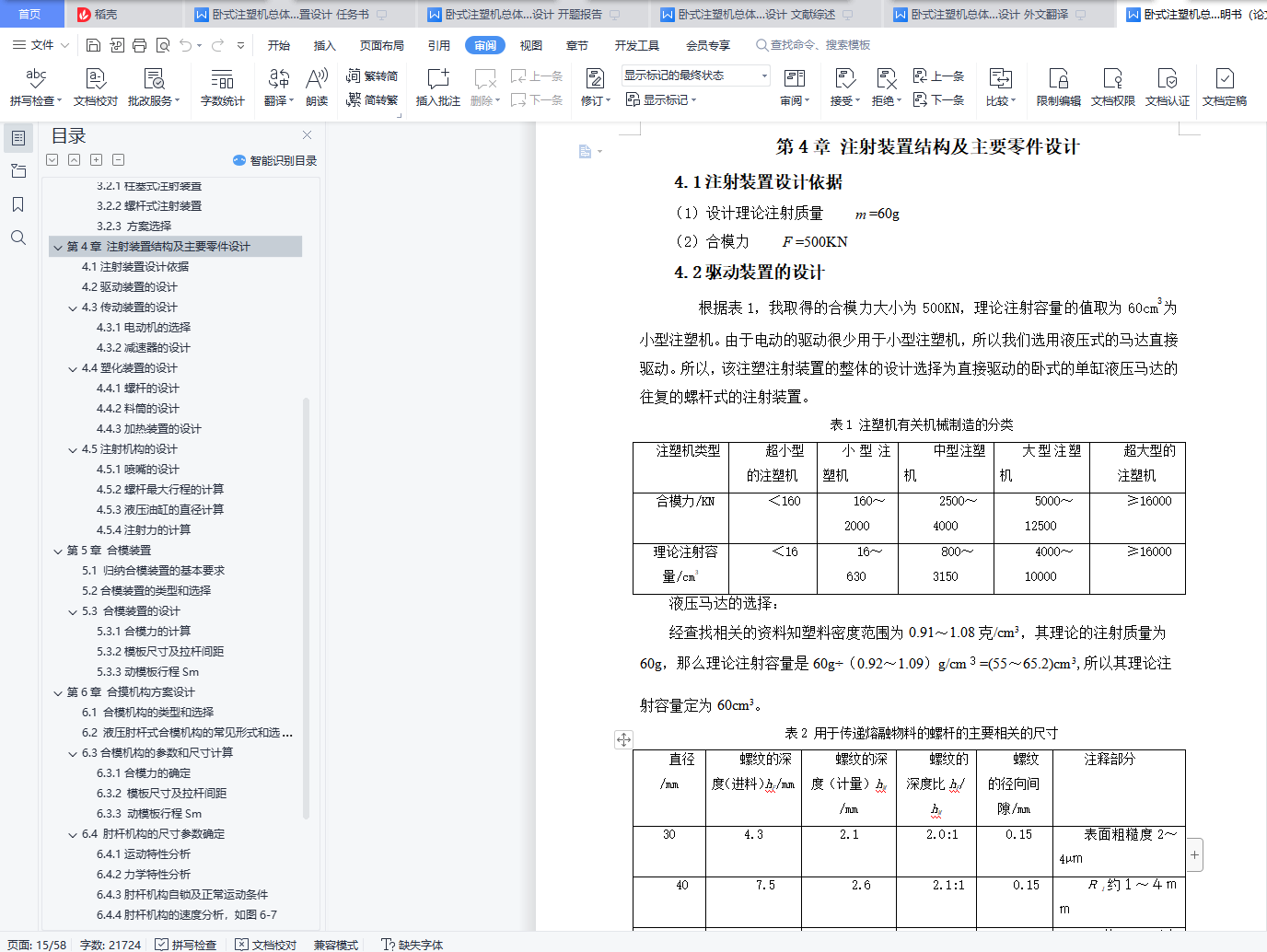

卧式注塑机总体方案及合模装置设计 说明书(论文)+任务书+开题报告+文献综述+外文翻译及原文+答辩PPT+cad图纸

摘 要

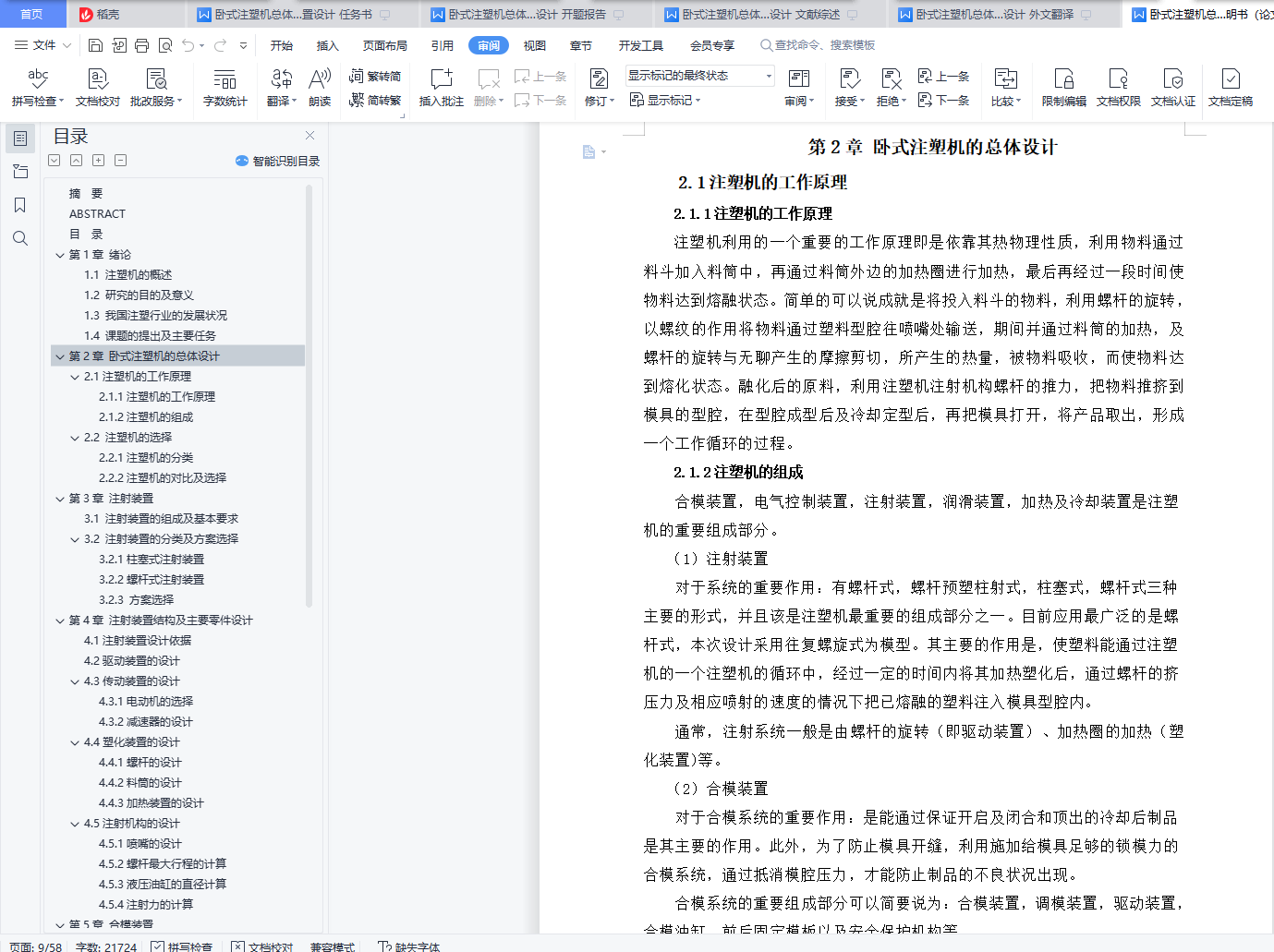

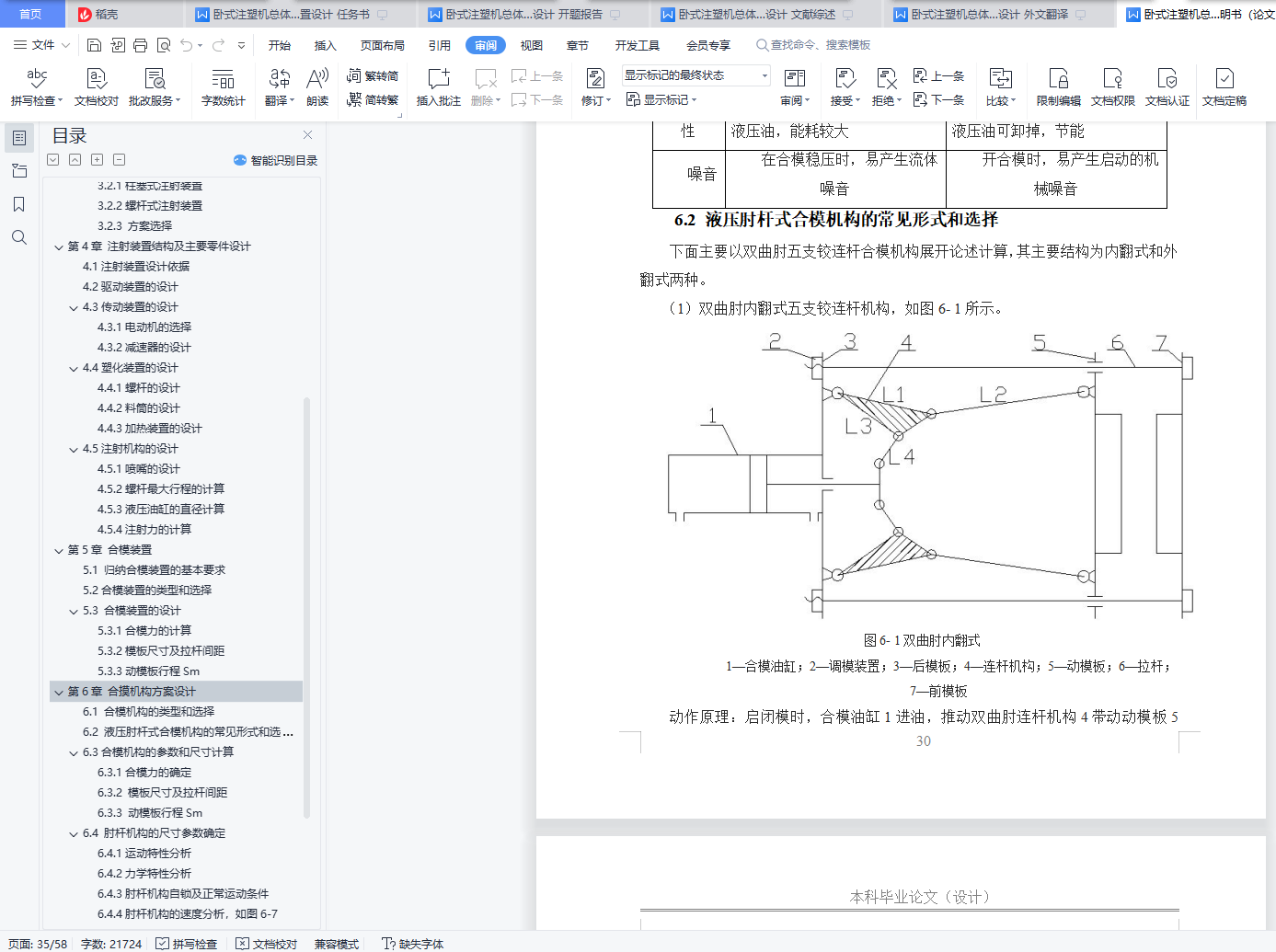

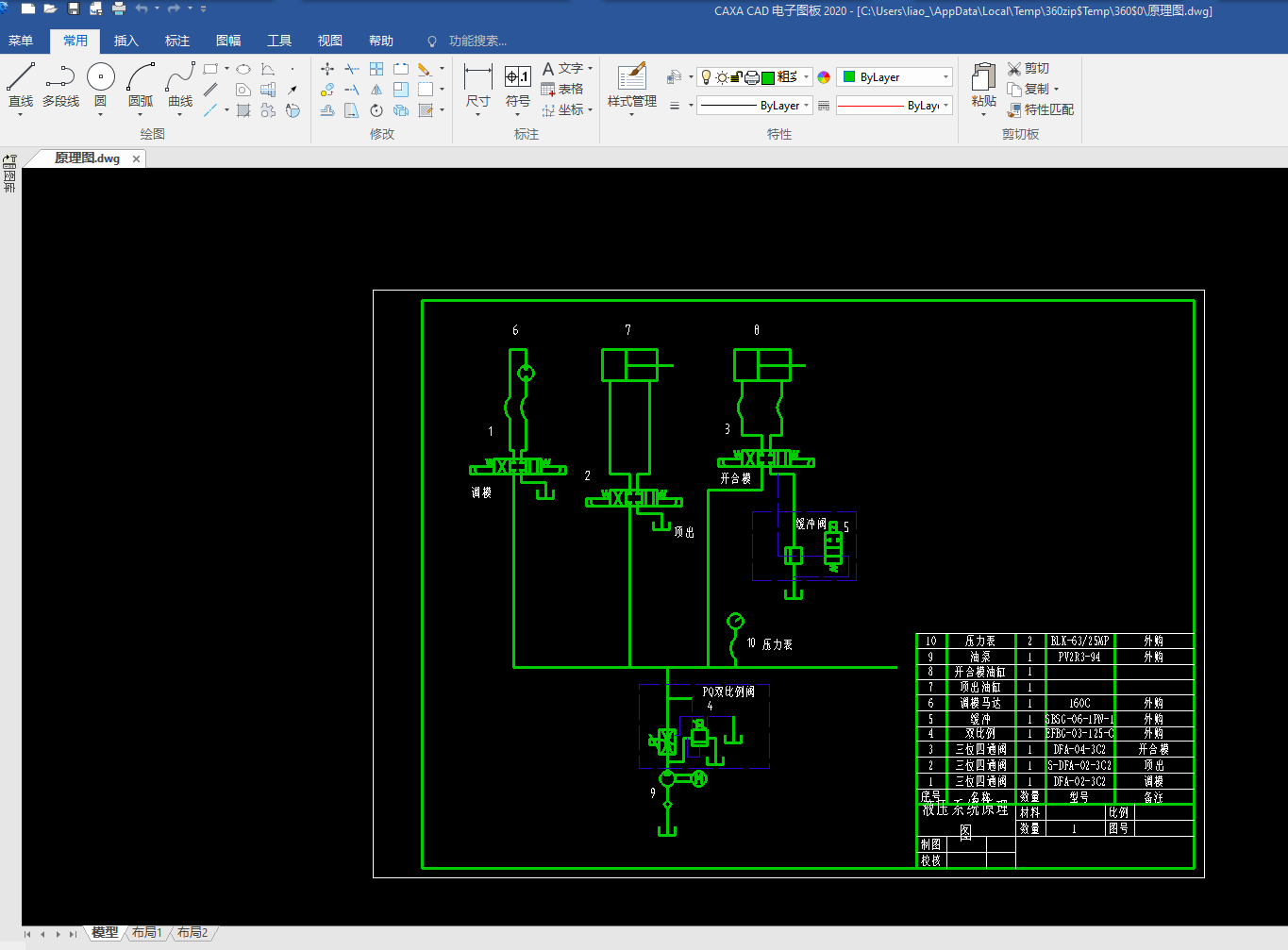

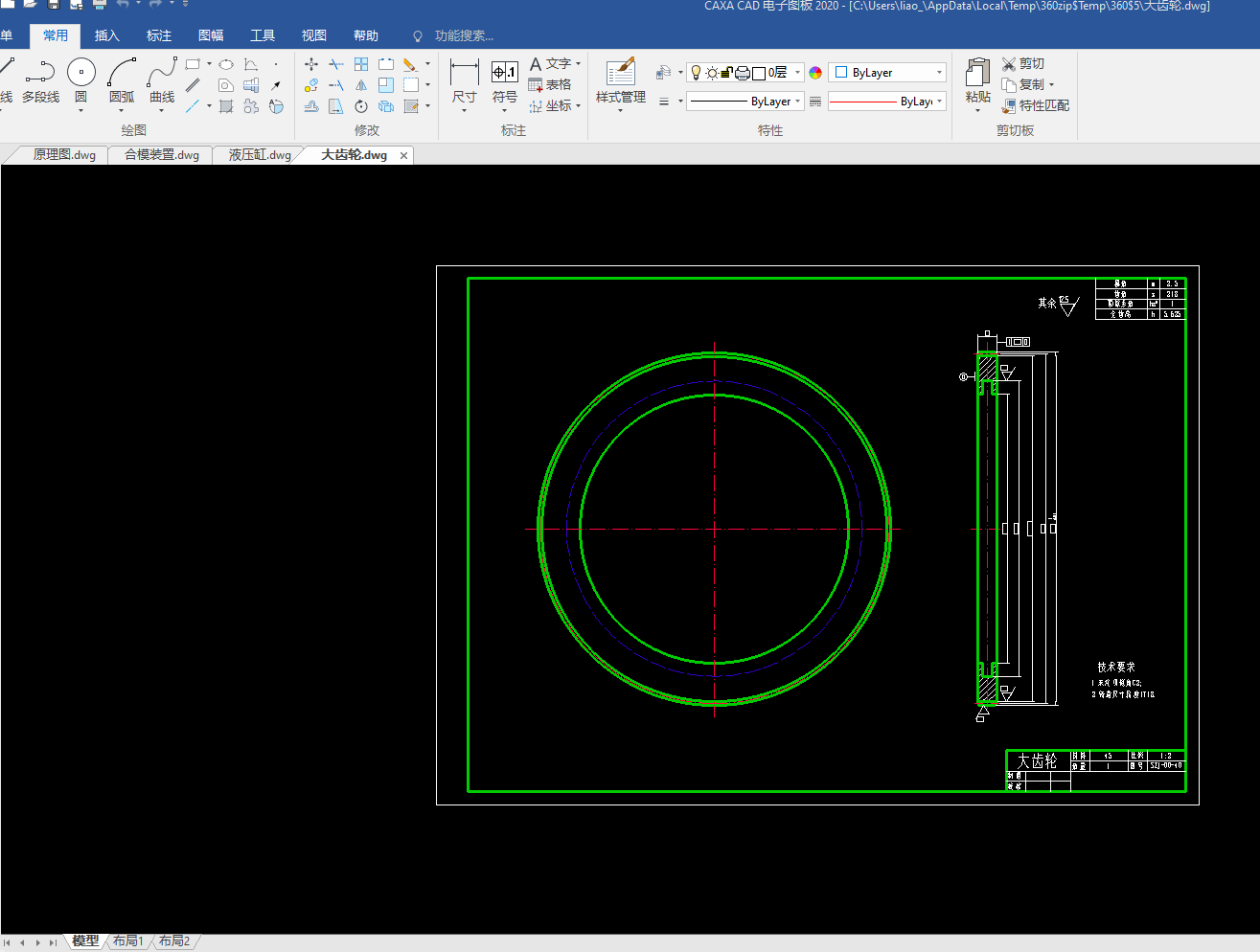

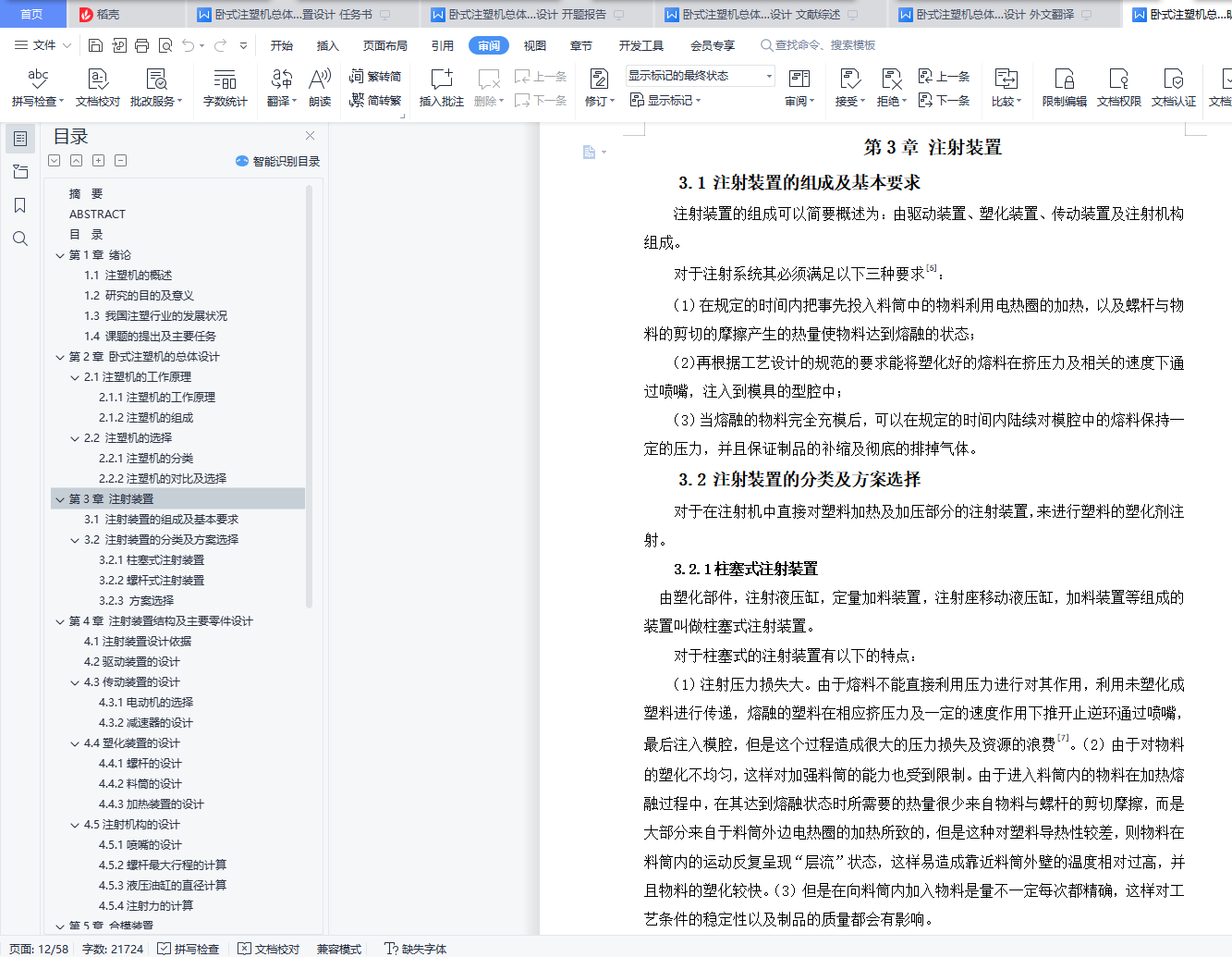

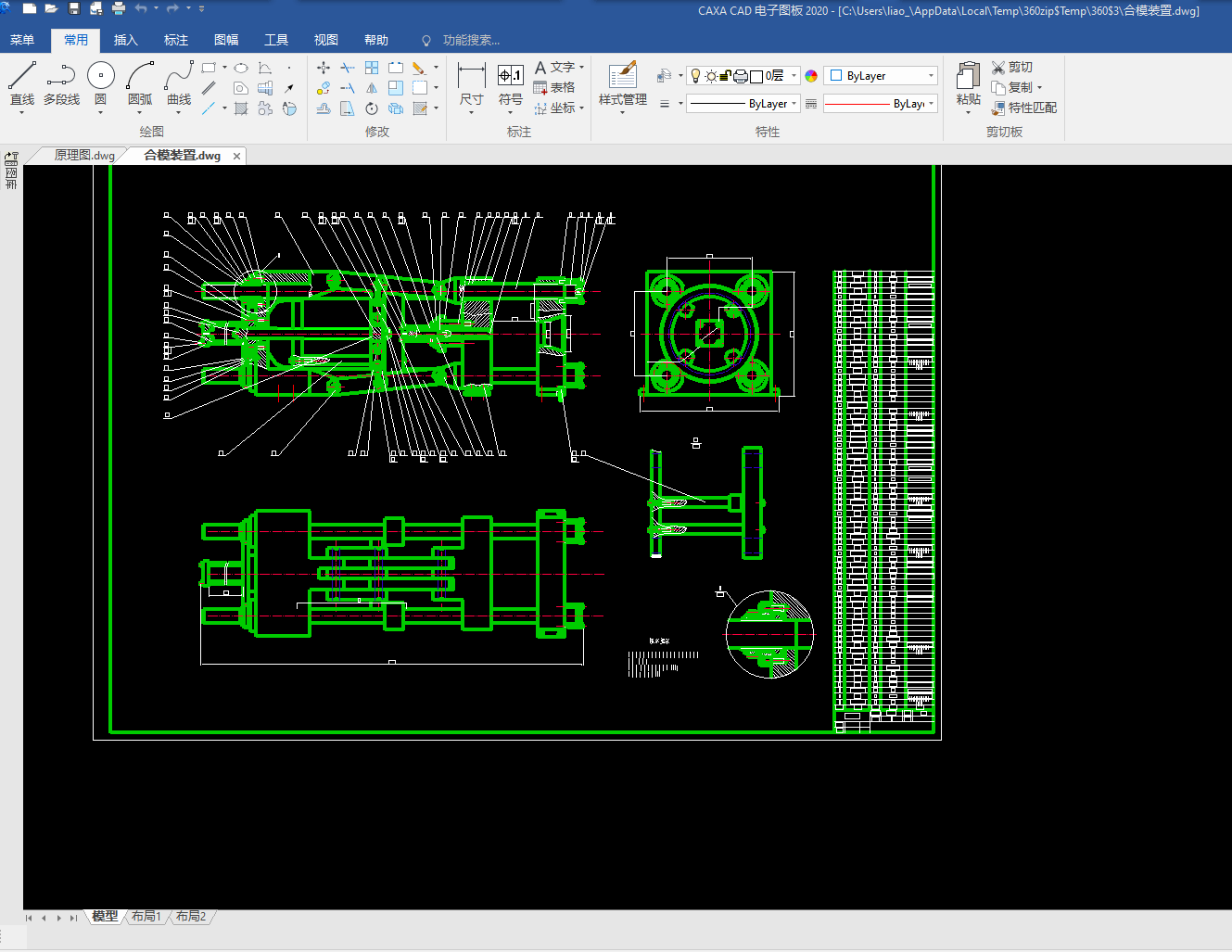

本次设计为卧式注射机合模机构设计,所设计的合模机构可以保证模具可靠的闭锁。对调模结构进行设计,详细的计算锁模机构连杆的规格。卧式注射机合模机构是保证模具可靠的闭锁和实现模具启闭动作及顶出塑件的部件,是注塑机核心结构之一,是现代科技发展最迅猛的研究领域。研究它可以把握机械设计的前沿动态,可以为将来的设计制造实践打下坚实的基础。

注塑机是一种通用设备,通过它与不同专用注塑模具配套使用,能够生产出多种类型的注塑制品。而注塑机合模结构是保证模具可靠的闭锁和实现模具启闭动作及顶出塑件的部件,是注塑机核心结构之一。为了保证模具不被很大的压力冲击毁坏,必须由某些机构产生很大的外力抵抗外力冲击并且保证模具可靠的闭锁。这就是研究卧式注射机合模结构意义所在。

关键词:注塑机;注射成型;合模装置;注射装置

ABSTRACT

This design is a horizontal injection machine die-closing mechanism design, the design of die-closing mechanism can ensure the mold reliable locking. Design the adjusting structure and calculate the specification of the connecting rod of the locking mechanism in detail. The die closing mechanism of horizontal injection machine is one of the core structures of injection molding machine and the most rapid research field of modern science and technology. It can grasp the frontier dynamics of mechanical design and lay a solid foundation for future design and manufacturing practice.

Injection molding machine is a general equipment, through it and different special injection mold matching use, can produce a variety of injection products. The mould closing structure of injection molding machine is one of the core structures of injection molding machine, which ensures the reliable locking of mould and realizes the opening and closing action of mould and the ejection of plastic parts. In order to ensure that the mould is not destroyed by great pressure impact, it is necessary for some mechanisms to produce great external force to resist the external force impact and to ensure the reliable locking of the mould. This is the significance of studying the die structure of horizontal injection machine.

Keywords: injection molding machine; injection molding; mold closing device; injection device

目 录