隐形眼镜盒体的注塑模设计 说明书(论文)+任务书+开题报告+CAD图纸+UG三维图

隐形眼镜盒体的注塑模设计

专业:交通运输 学 号:201610111120

学生:张三 指导教师:李四/王五

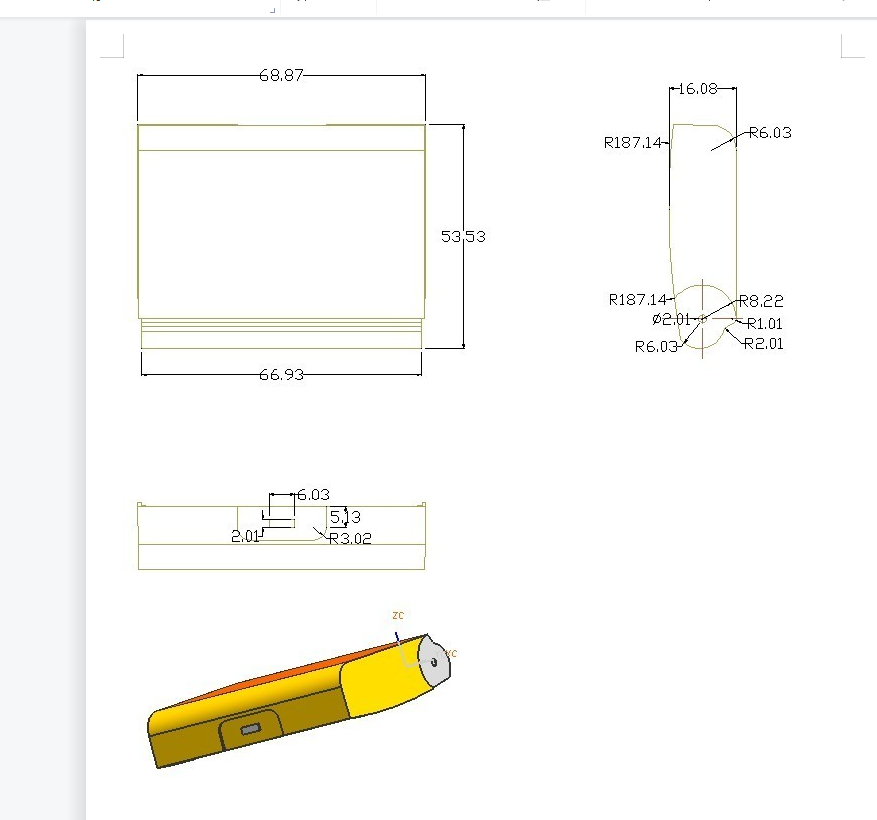

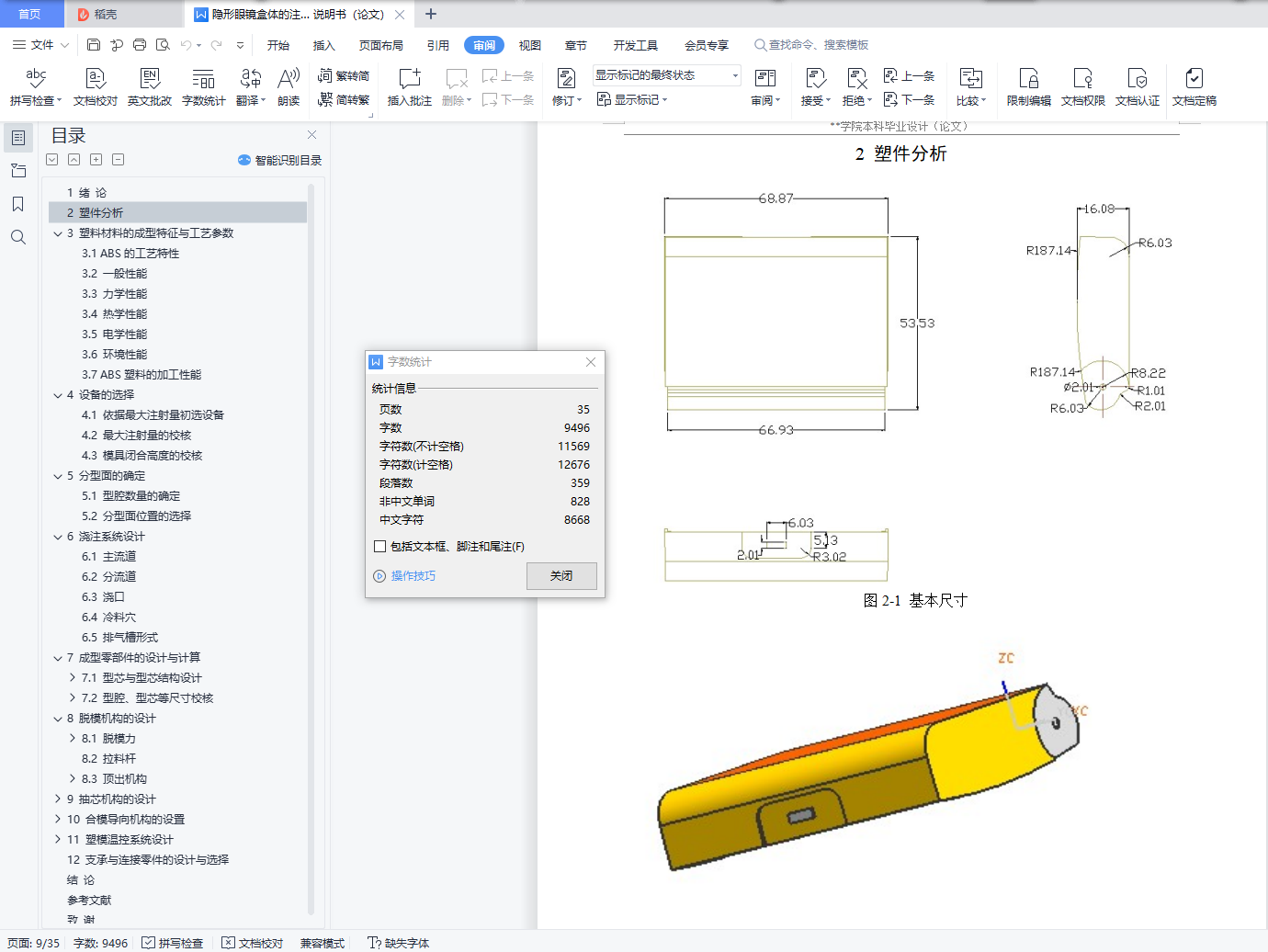

摘要:此次眼镜盒的设计,从开始确定产品到最后完成都严格按照毕业说明书内容要求进行。第一是对所要设计的产品进行分析、测量,然后查阅相关资料确定使用的材料和性能,然后用UG画出产品实体,并用UG分析产品的合理性。

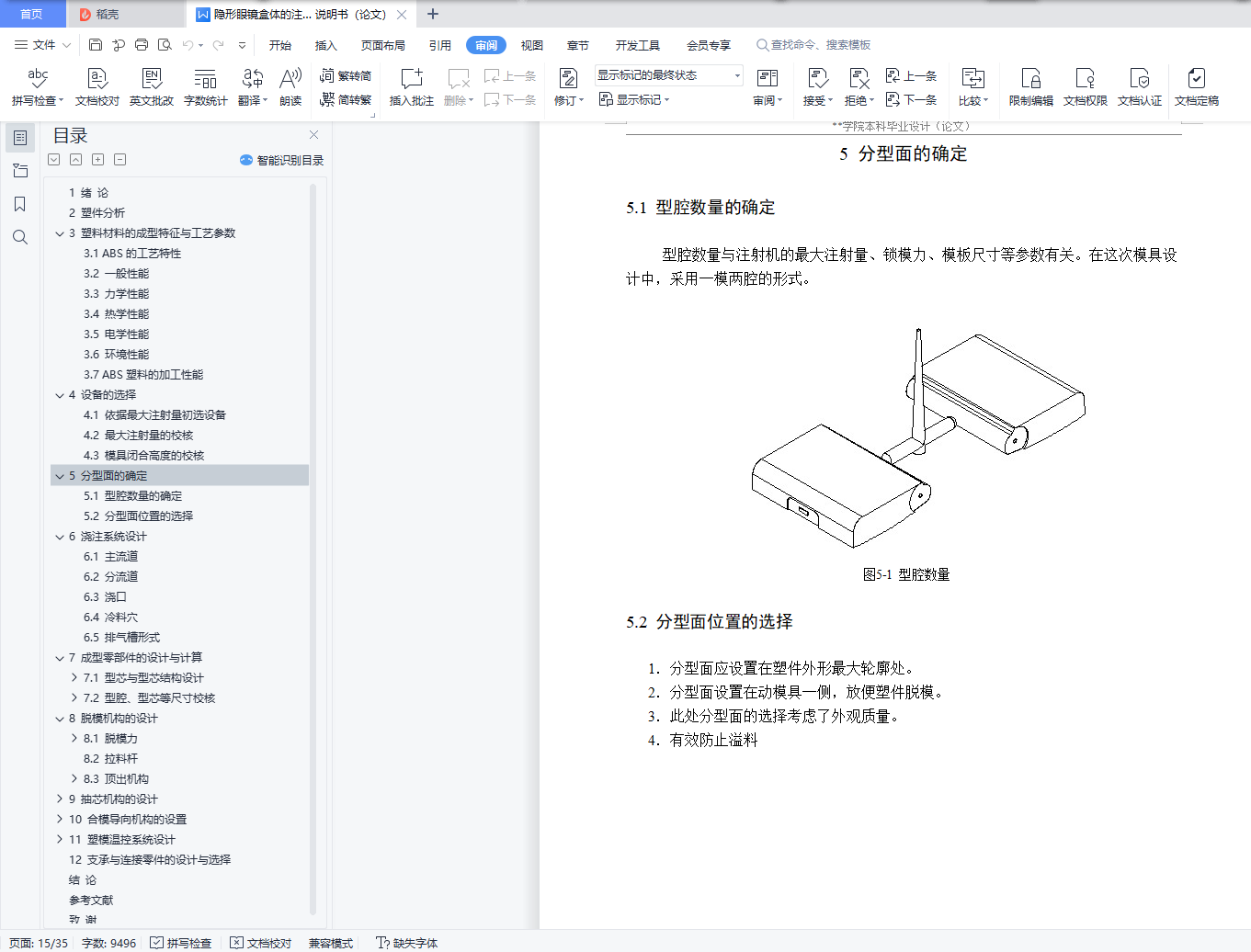

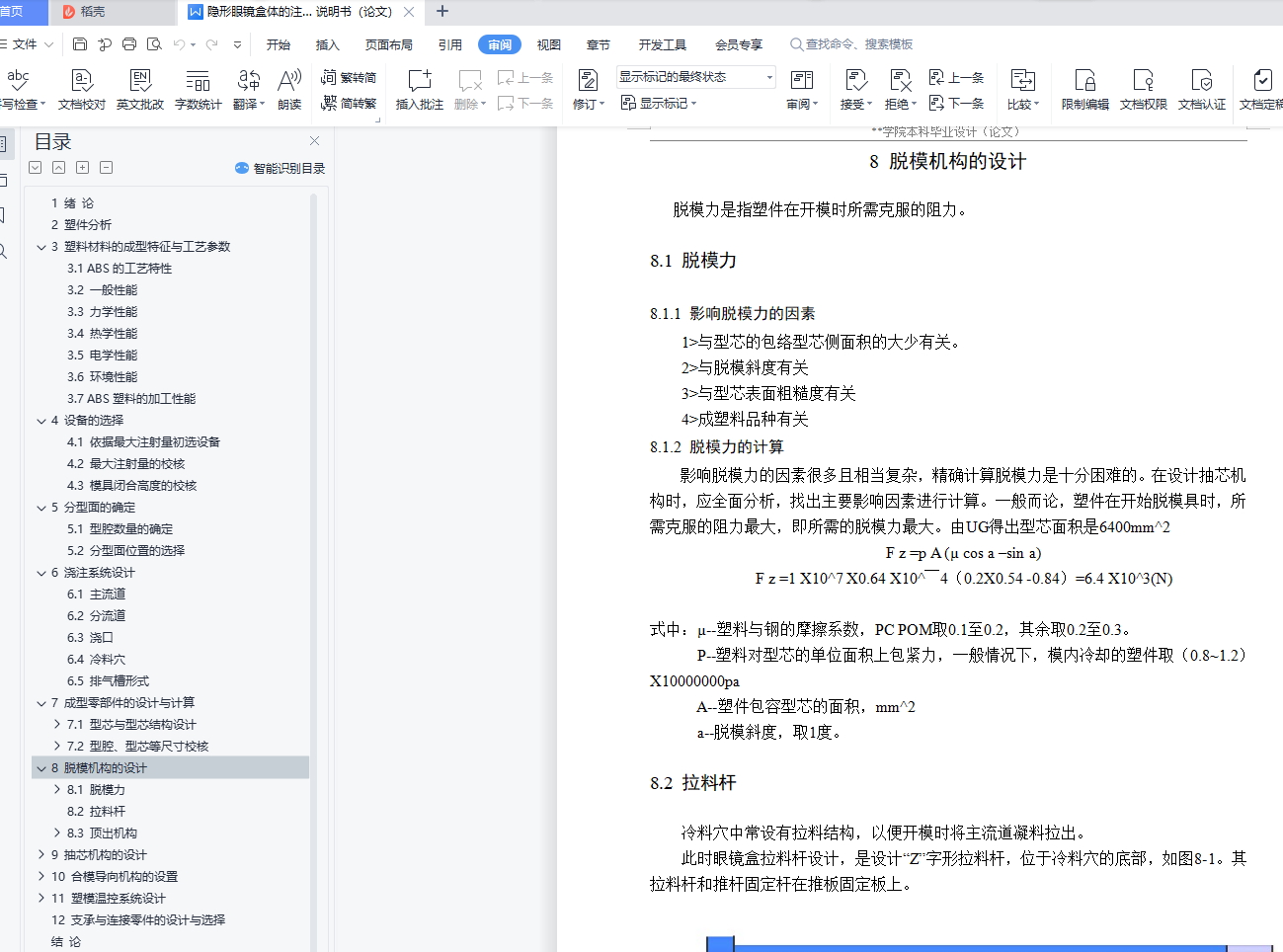

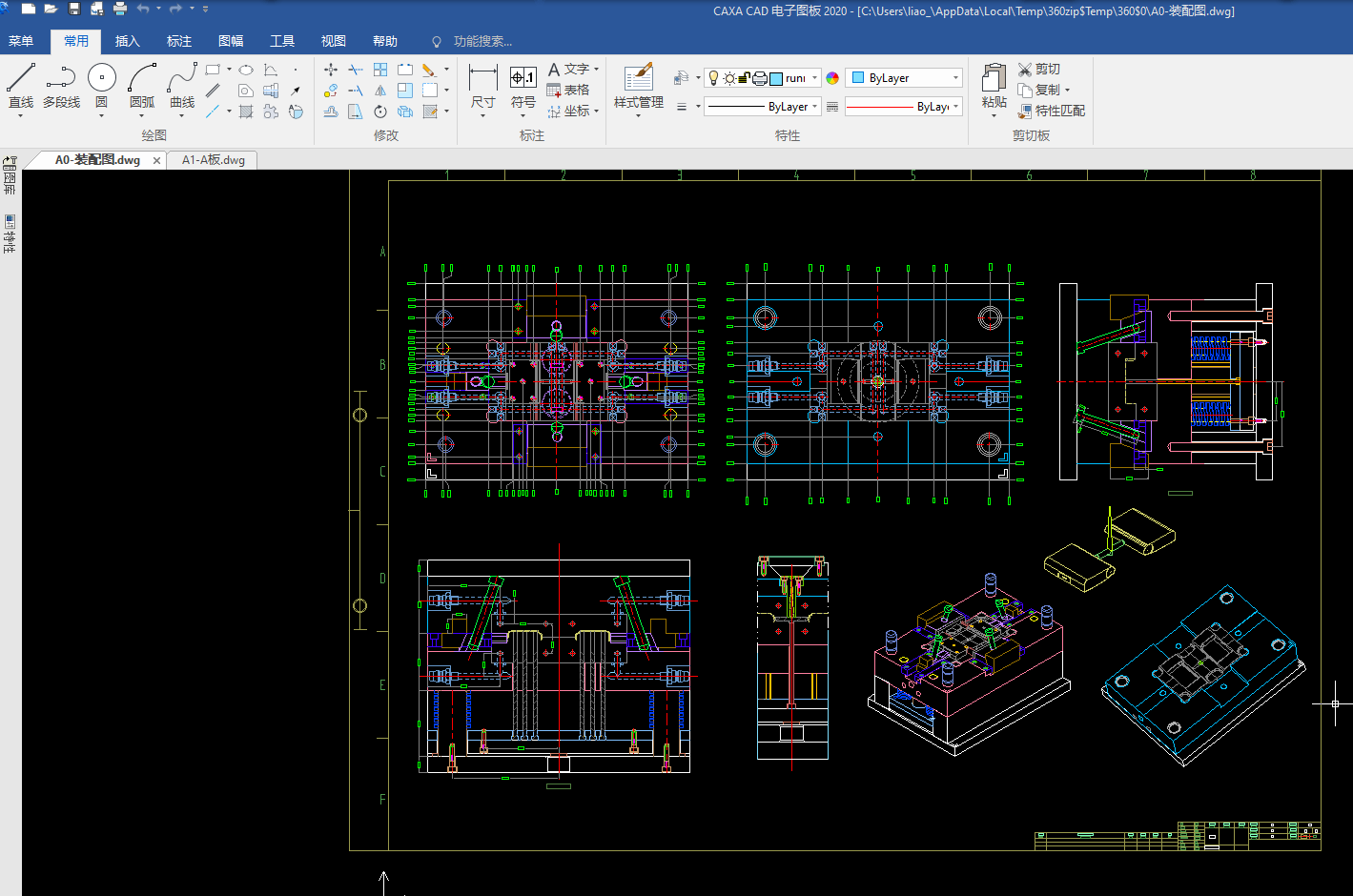

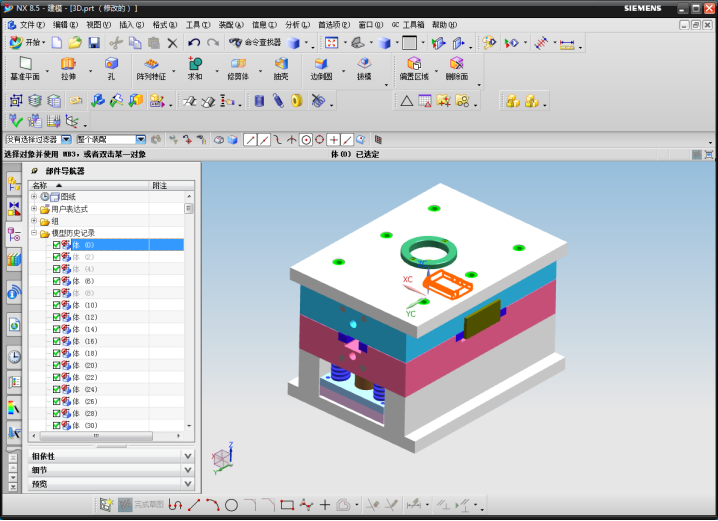

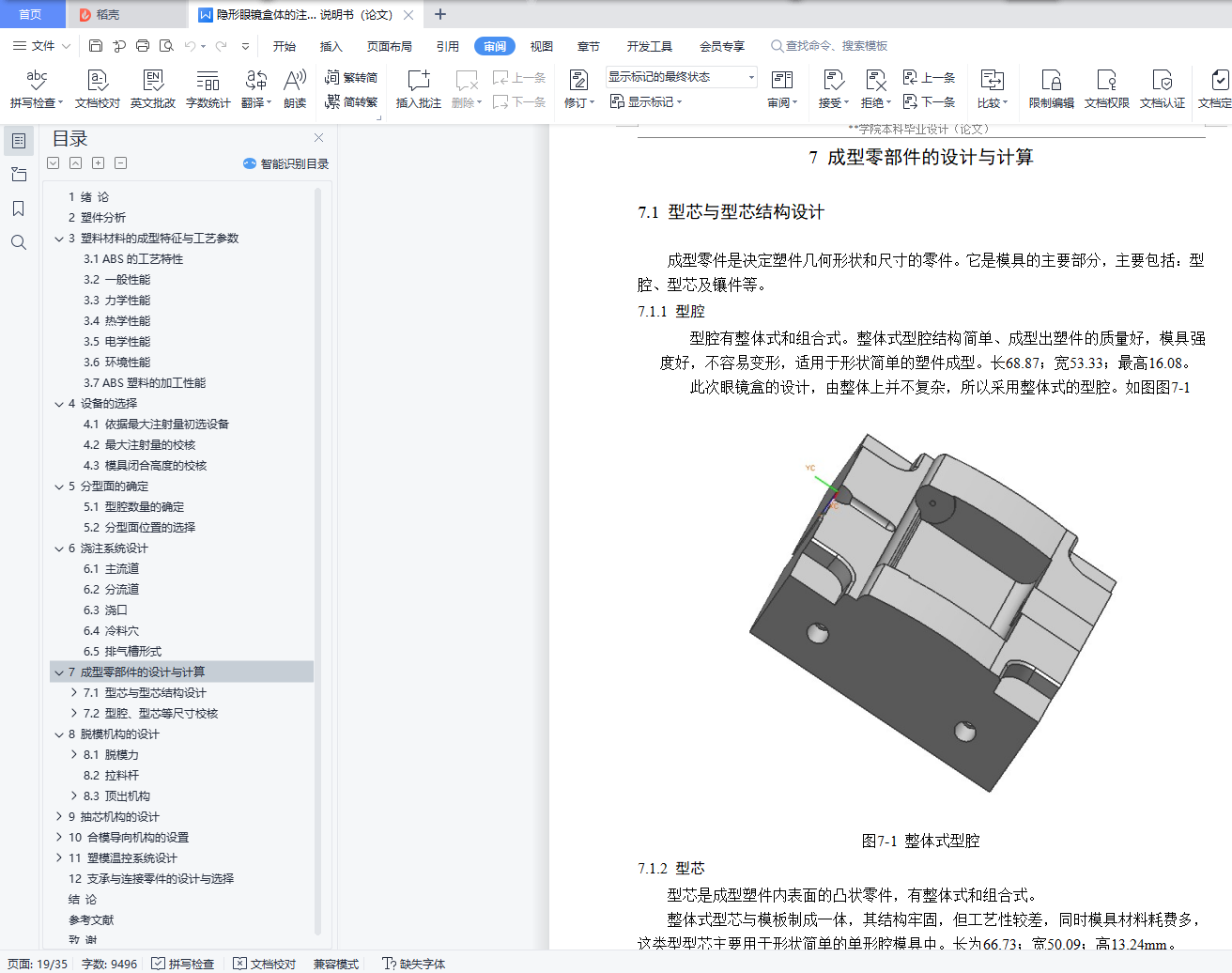

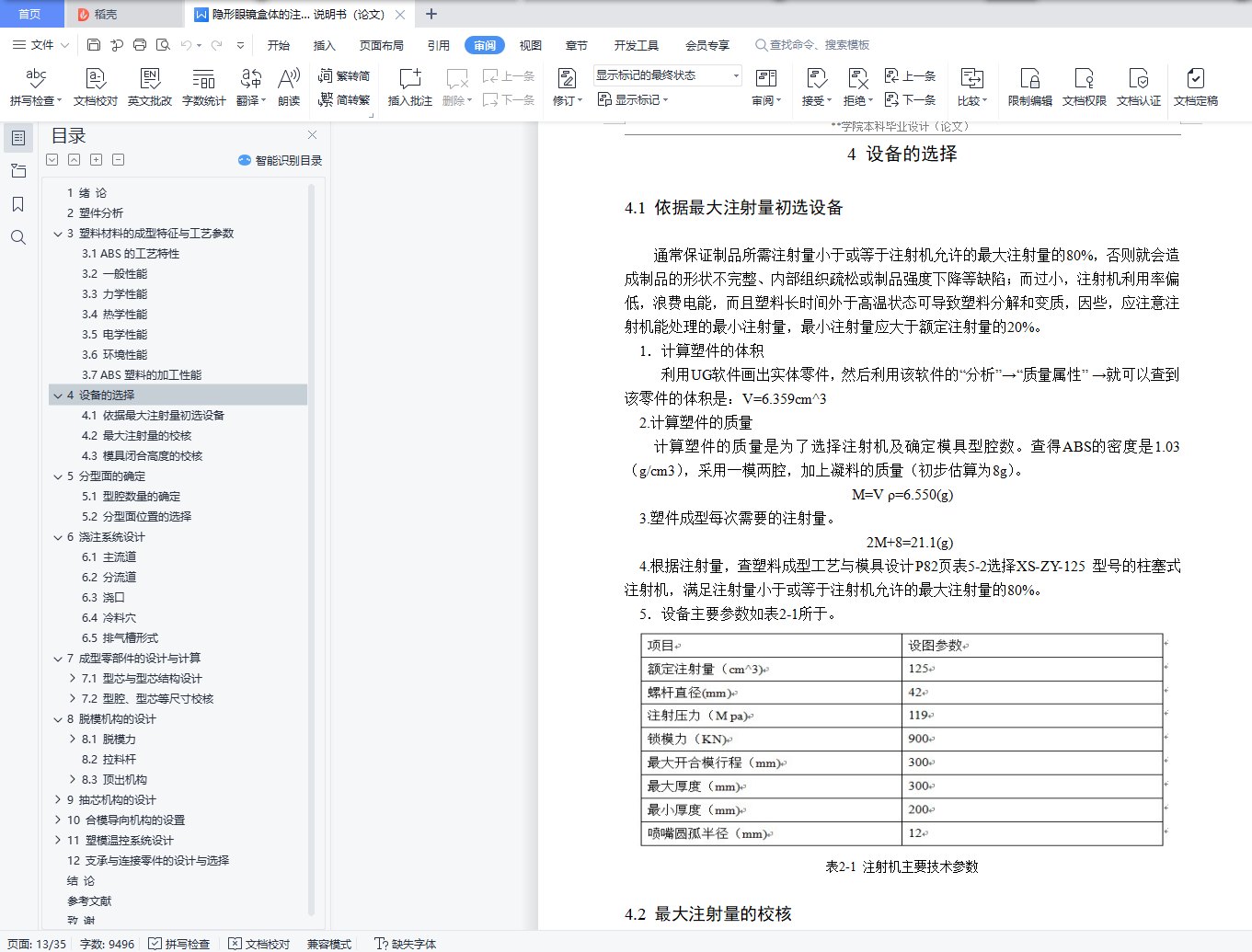

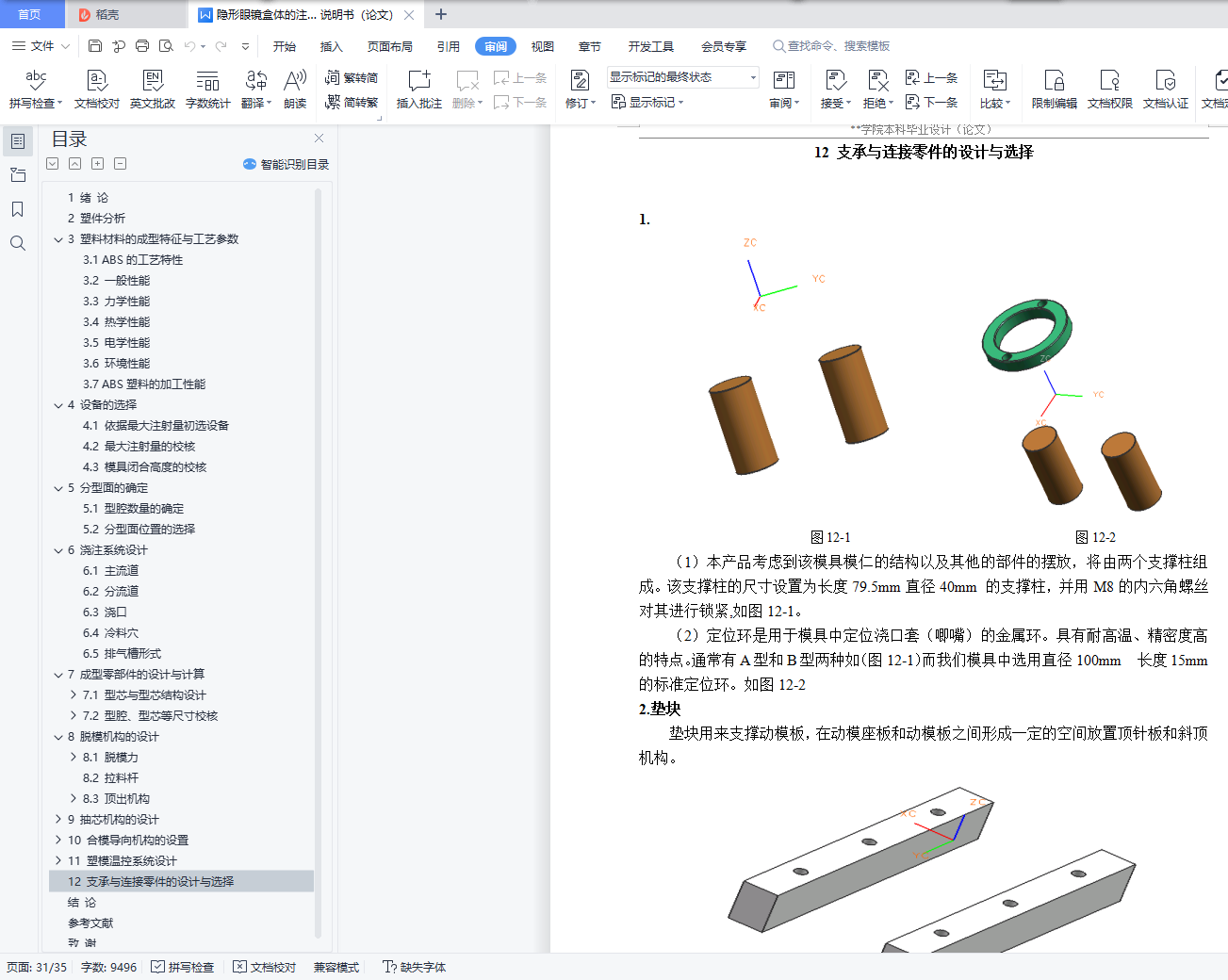

第二根据实体模具型对零件进行结构分析,确定整个注塑循环系统,包括基本模架、开模具行程,开模、复位机构,冷却系统等基本参数,对具体结构零件分析计算。用UG对模具的型腔、型芯及其它零件进行三维造型,对其进行实体装配。

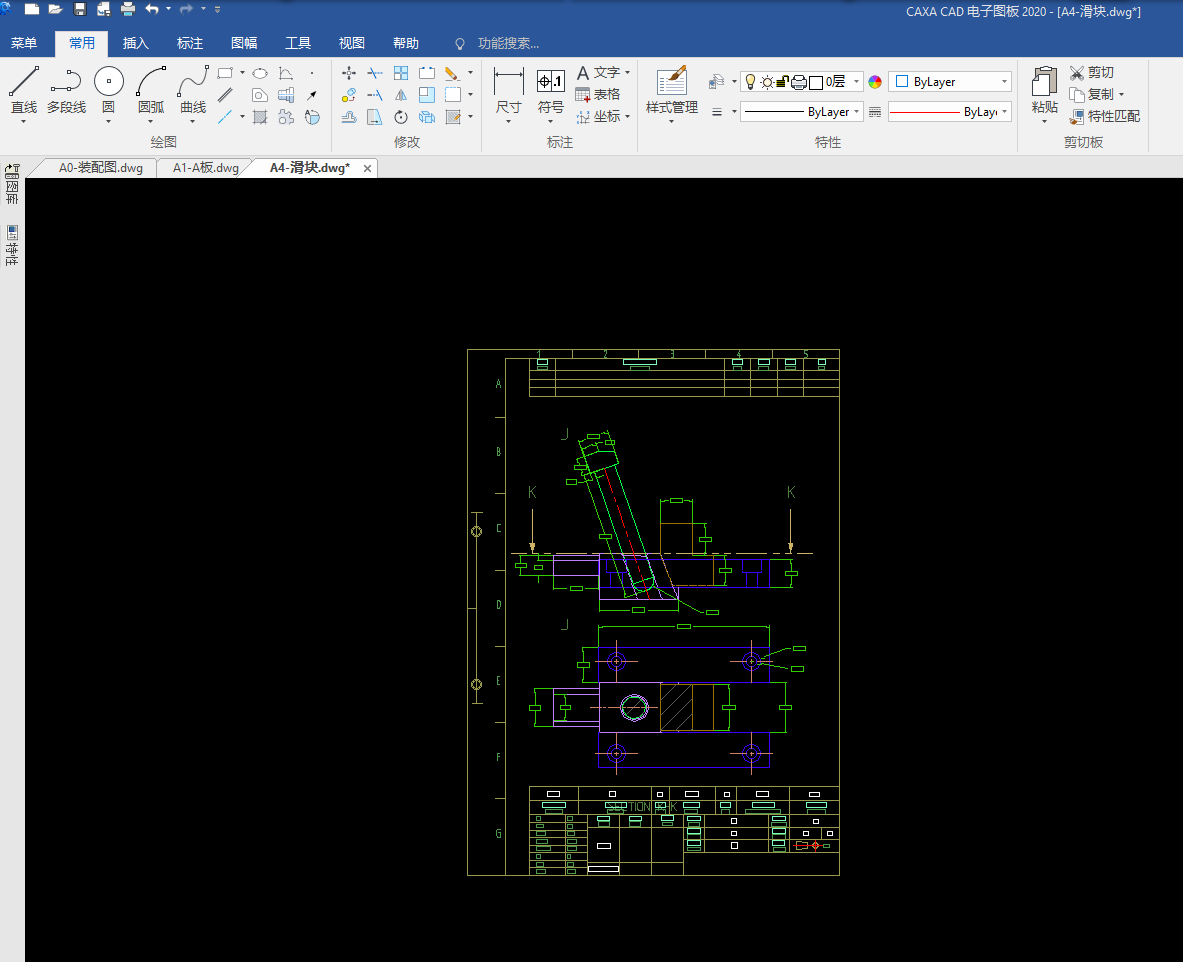

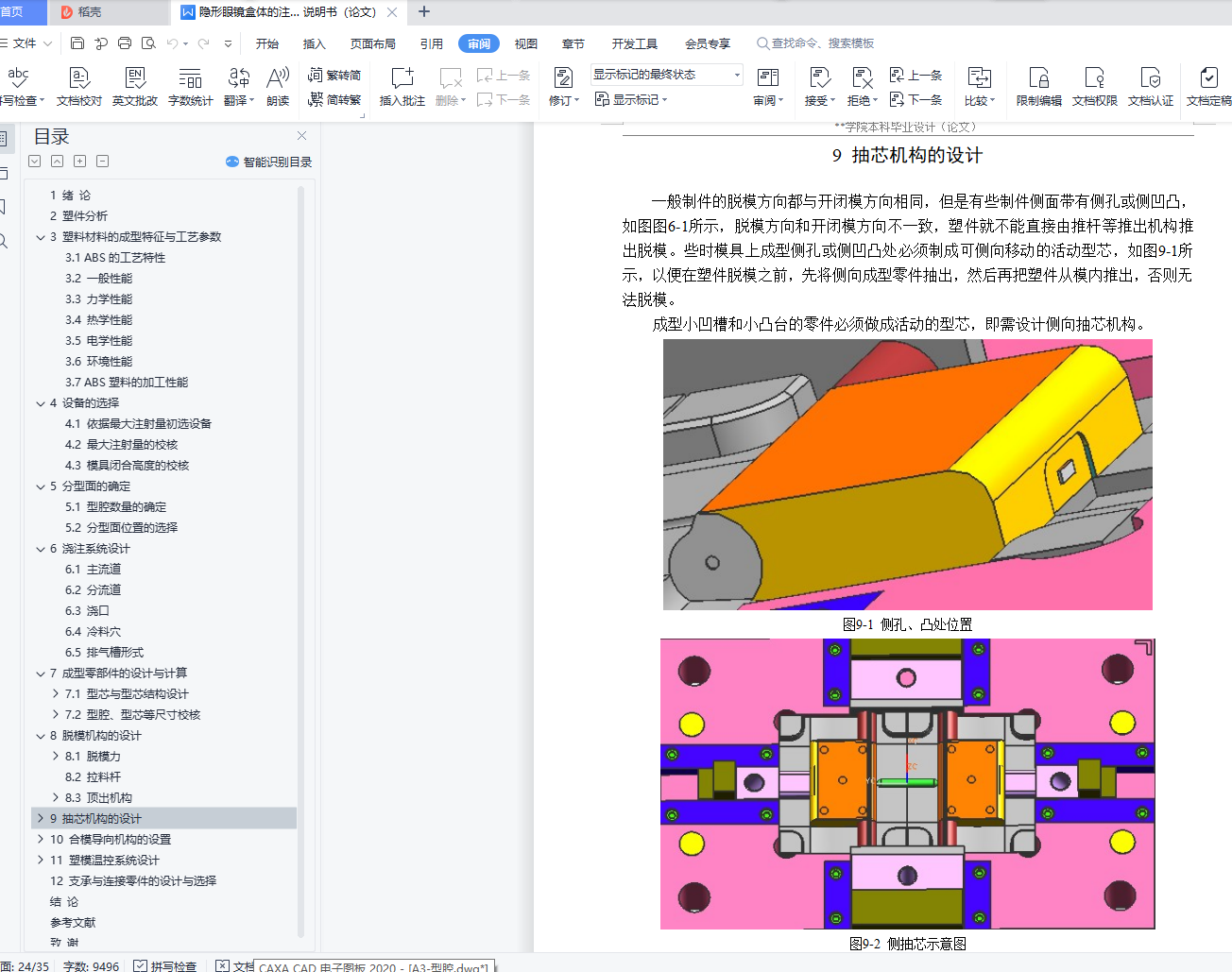

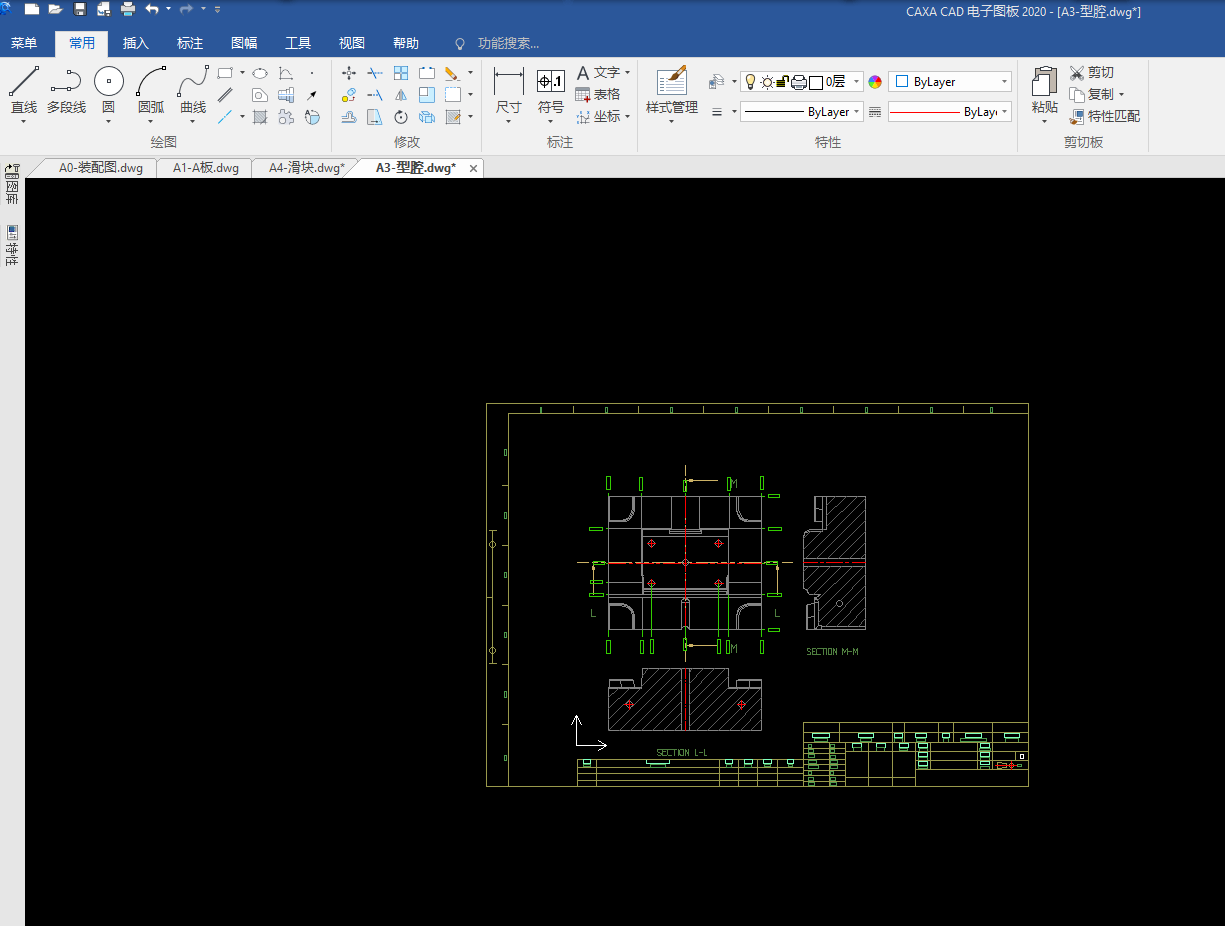

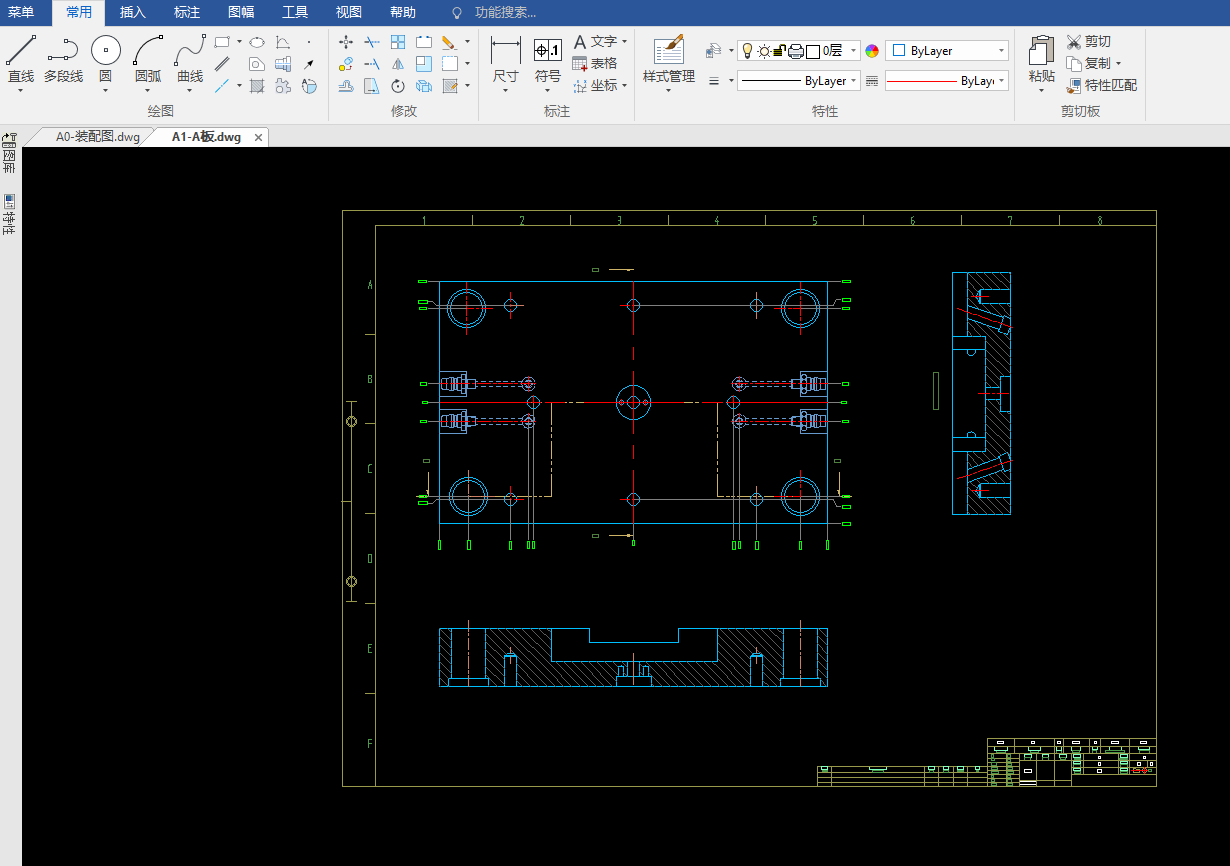

第三,用CAD绘制平面装配图及相关的零部件。本次设计的难点在于侧抽芯机构。最后编写一份说明书,对之前所做产品、工件步骤进行说明、计算。

关键词:眼镜盒模具;UG;侧抽芯

Design of Injection Mould for Contact Lens Box

Major:Mechanical Manufacture and Automation Student ID:201510111120

Student:Zhang San Instructor:Li Si/Wang Wu

Abstract:The design of the glasses box, from the beginning to the final completion of the product are strictly in accordance with the requirements of the graduation instructions. The first is to analyze and measure the products to be designed, then consult the relevant data to determine the materials and properties used, then draw the product entity with UG, and analyze the rationality of the products with UG.

Secondly, the structural analysis of the parts is carried out according to the solid mold type, and the whole injection cycle system is determined, including the basic parameters such as the basic mold frame, the opening stroke, the opening die, the reset mechanism, the cooling system and so on. A UG is used to shape the mold cavity, core and other parts in three dimensions and assemble them.

Third, use CAD to draw plane assembly drawings and related parts. The difficulty of this design lies in the side core pulling mechanism. Finally, a manual is prepared to explain and calculate the previous product and workpiece steps.

Keywords: glasses box mold; UG; side core pulling

目 录