长垫片连续冲压模县设计 说明书(论文)+开题报告+CAD图纸+Proe三维图

摘要

长垫片作为工业领域中常见的连接与密封元件,其需求量日益增加。为提高生产效率与产品质量,本设计针对长垫片的连续冲压模具进行了深入研究与开发。冲压作为一种高效、精确的金属加工方法,在机械、汽车、电子等多个行业中发挥着重要作用。长垫片的连续冲压模具设计,旨在通过优化模具结构与工艺参数,实现高效、自动化、高精度的长垫片生产。

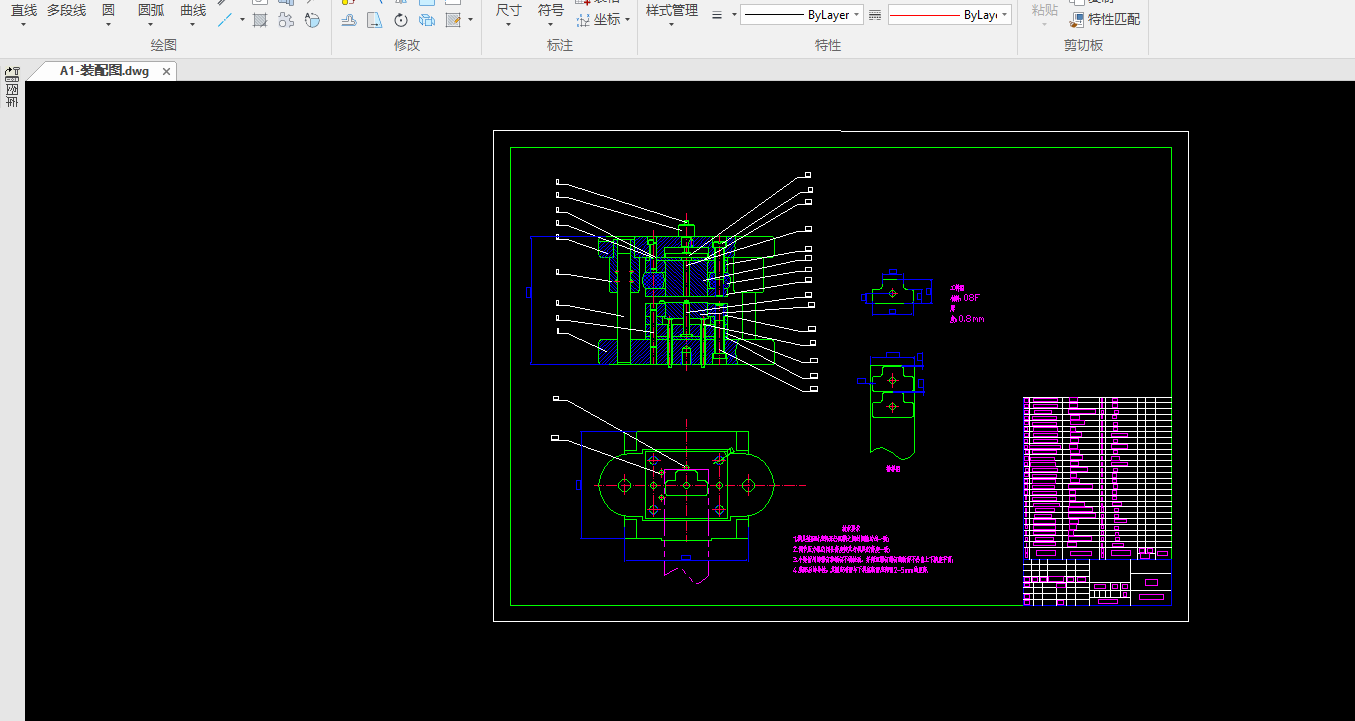

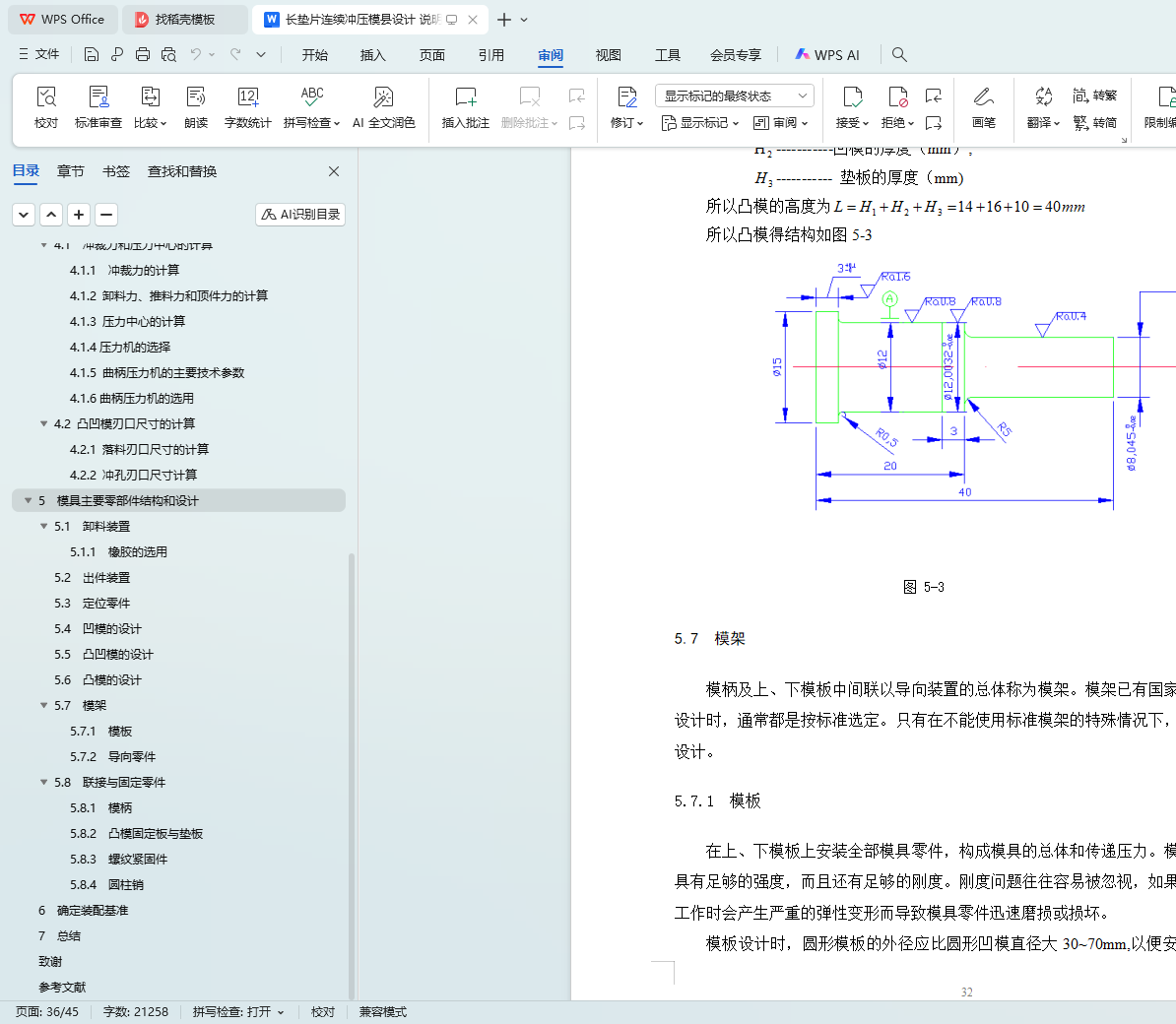

本设计首先分析了长垫片的材料特性与结构工艺性,确定了合适的冲压工艺方案。在排样设计中,通过合理的排样布局与材料利用率计算,有效降低了生产成本。随后,进行了详细的冲裁工艺计算,包括冲裁力、压力中心、凸凹模刃口尺寸等关键参数的确定,为模具的设计与制造提供了科学依据。

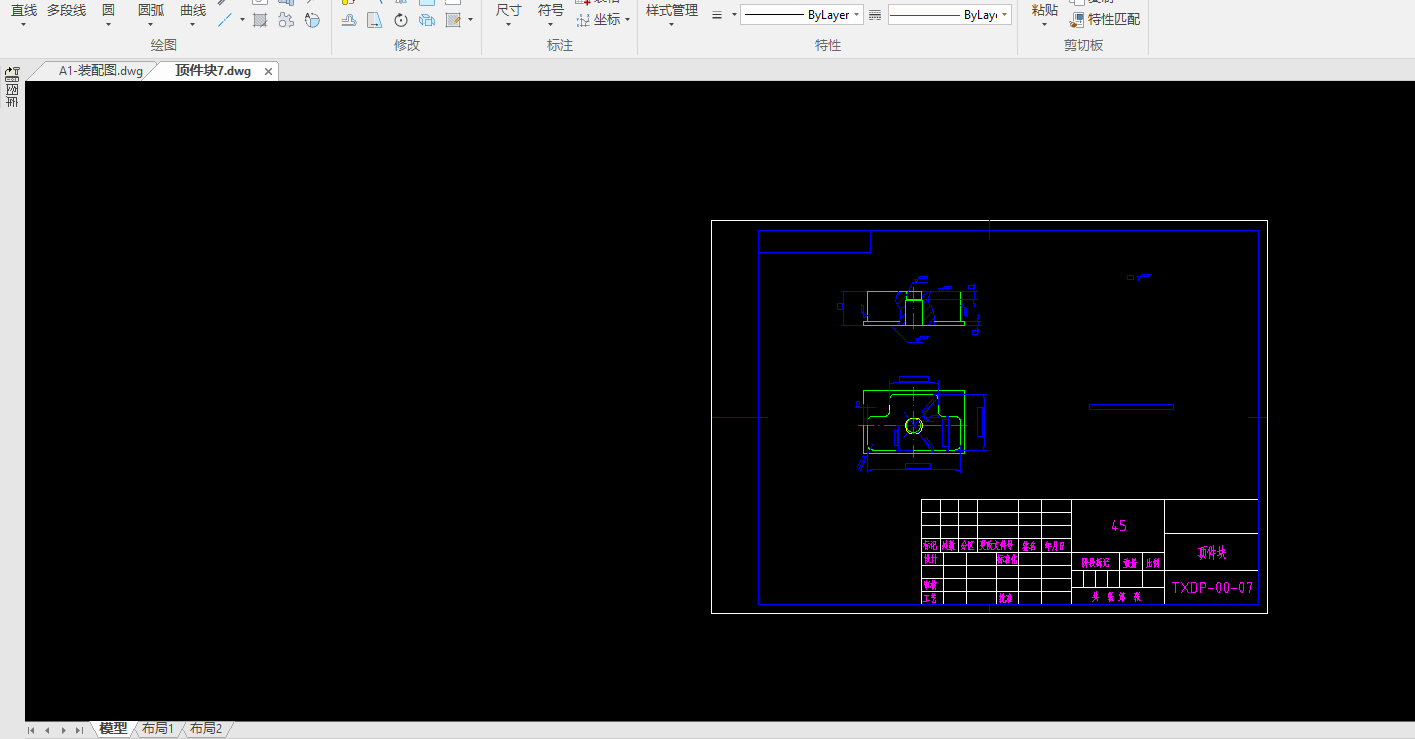

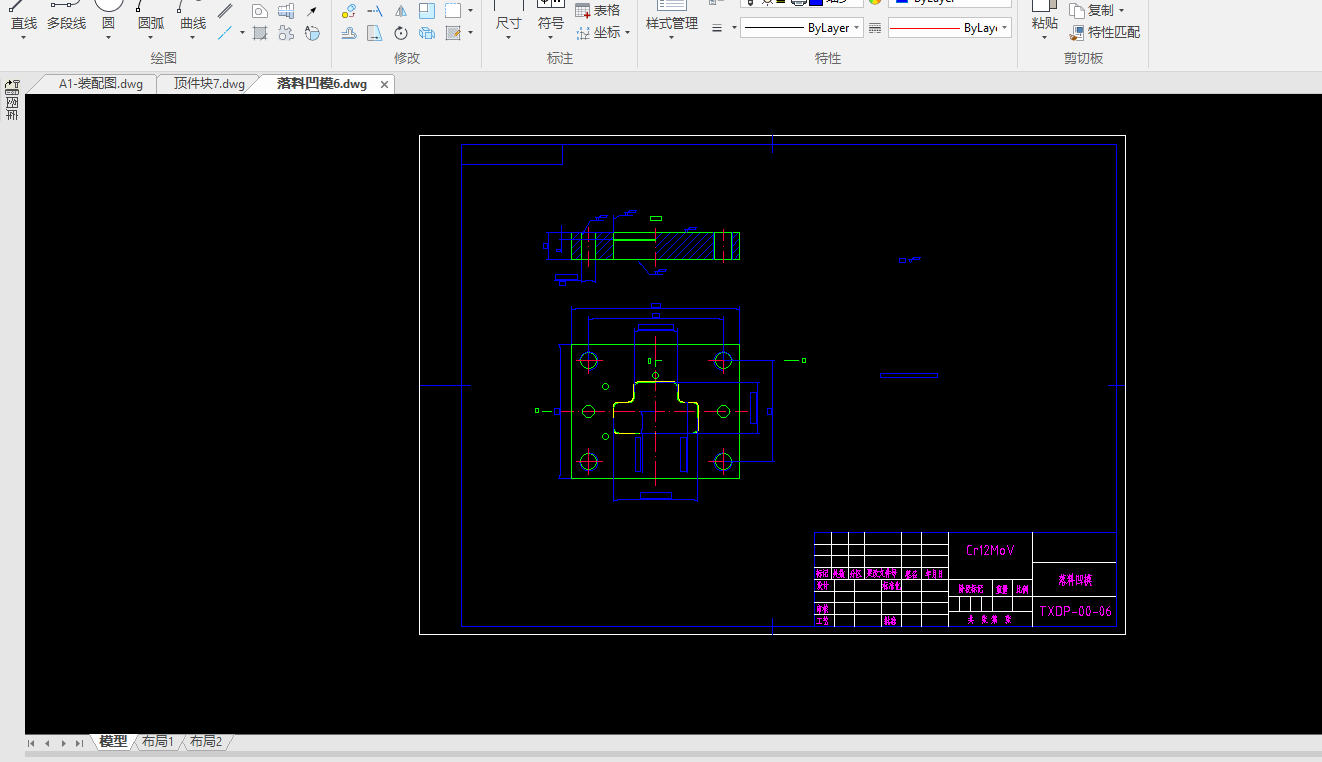

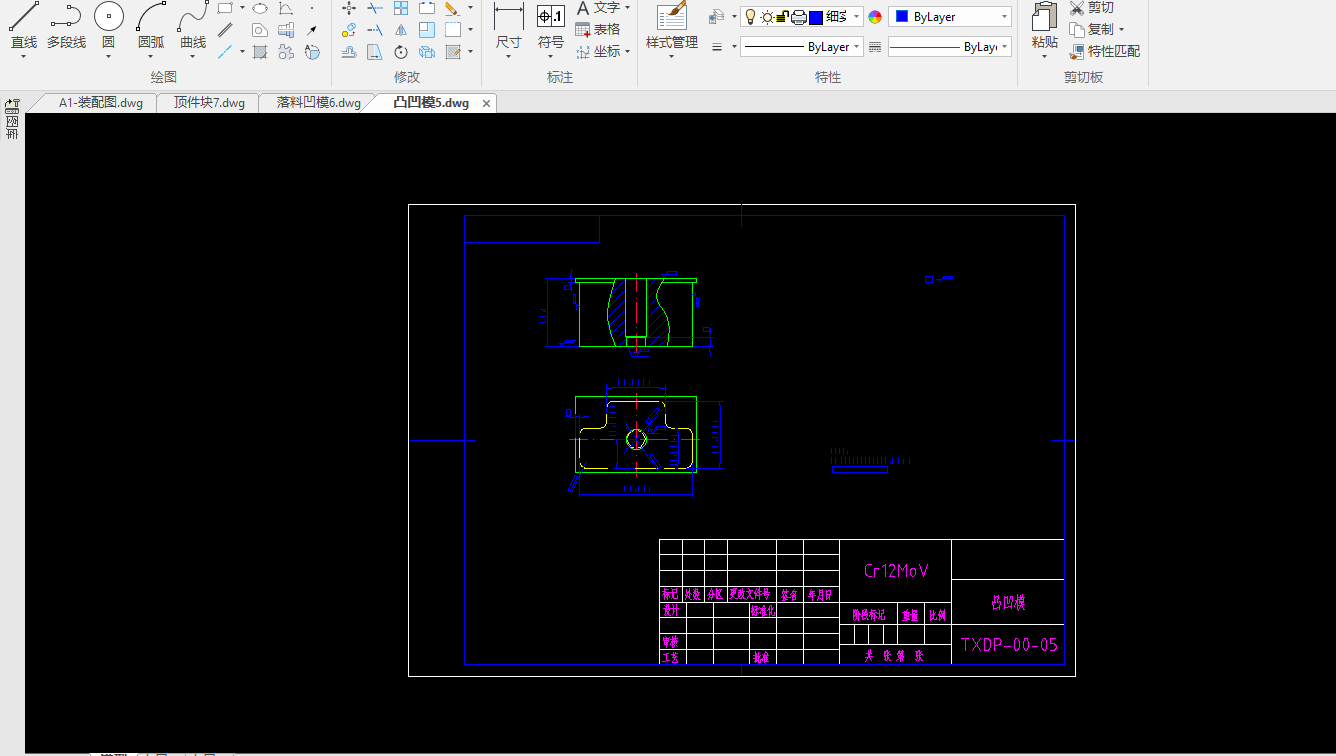

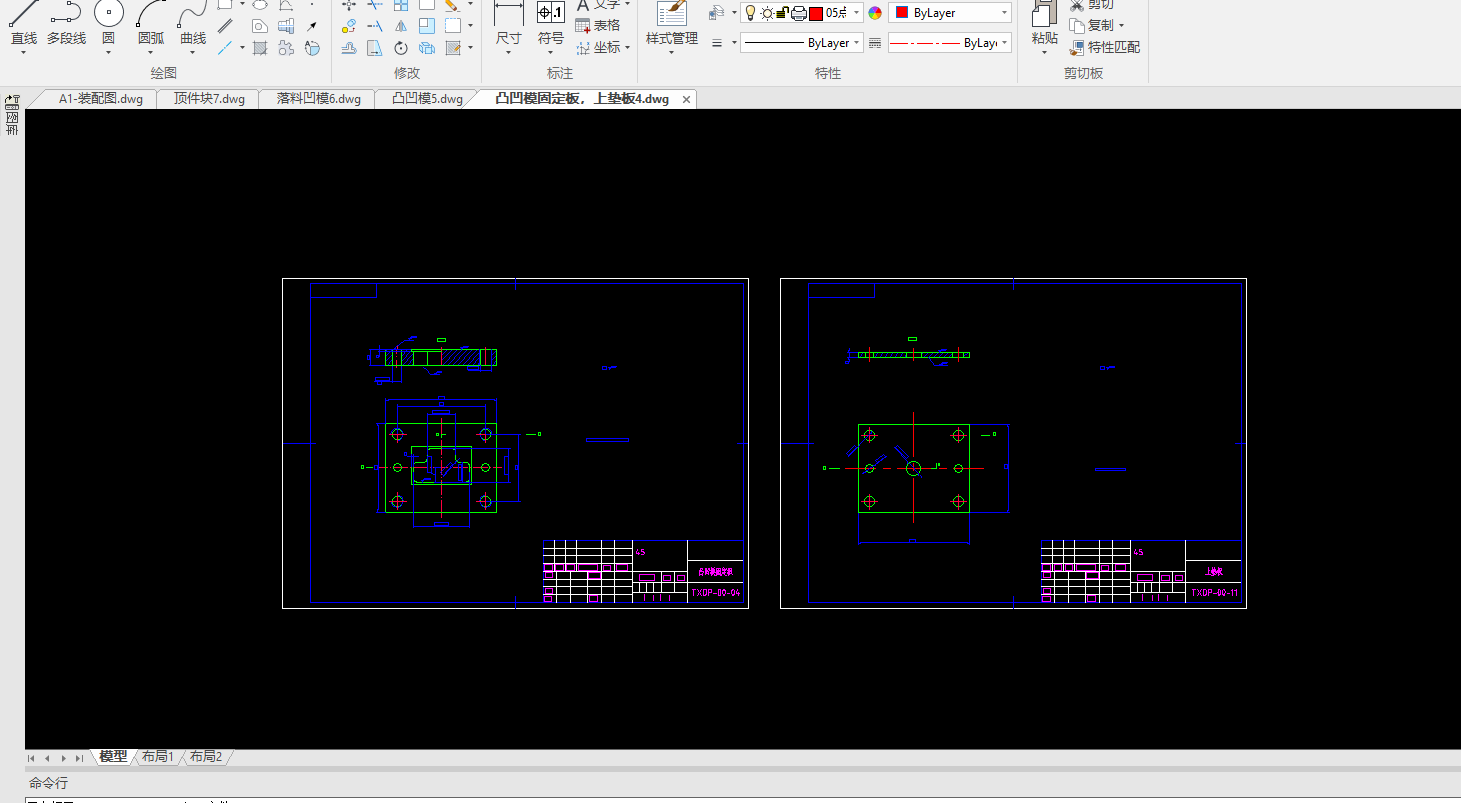

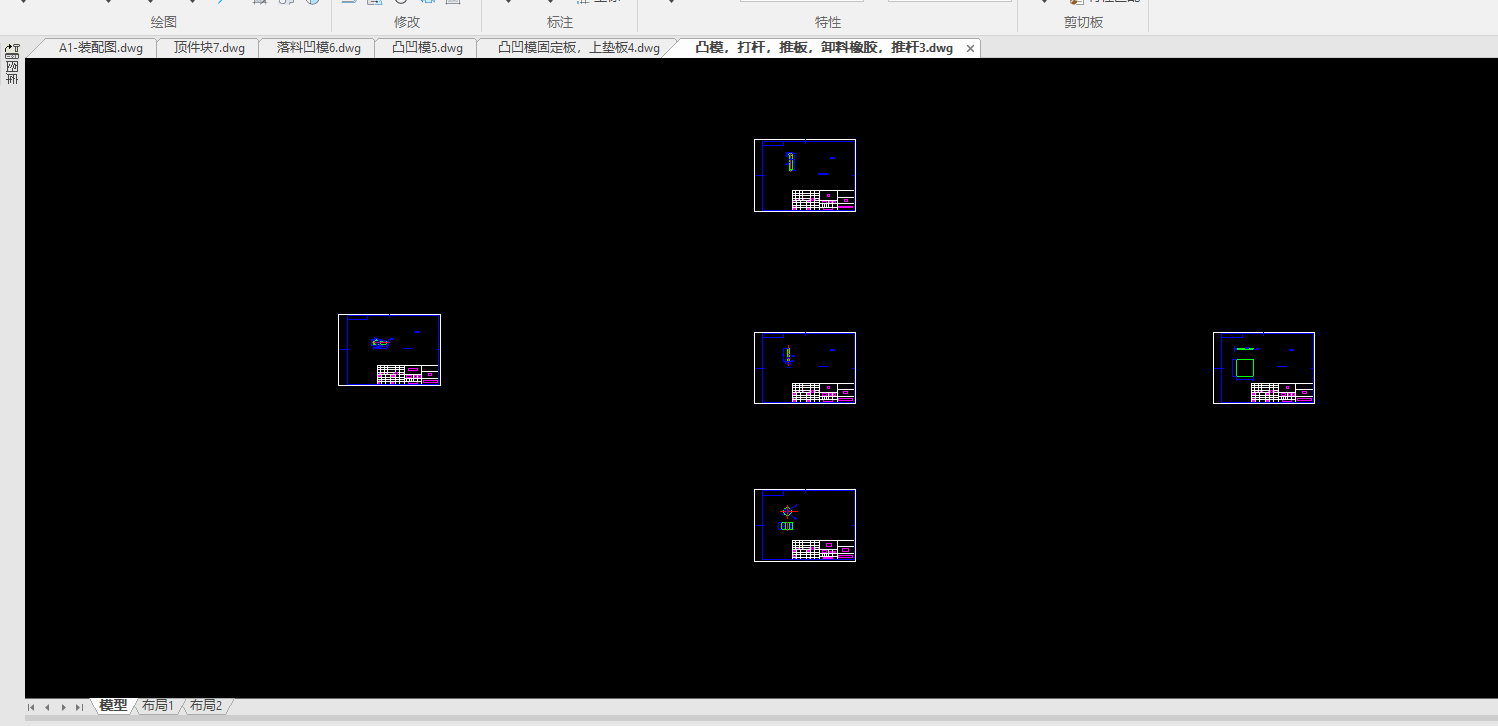

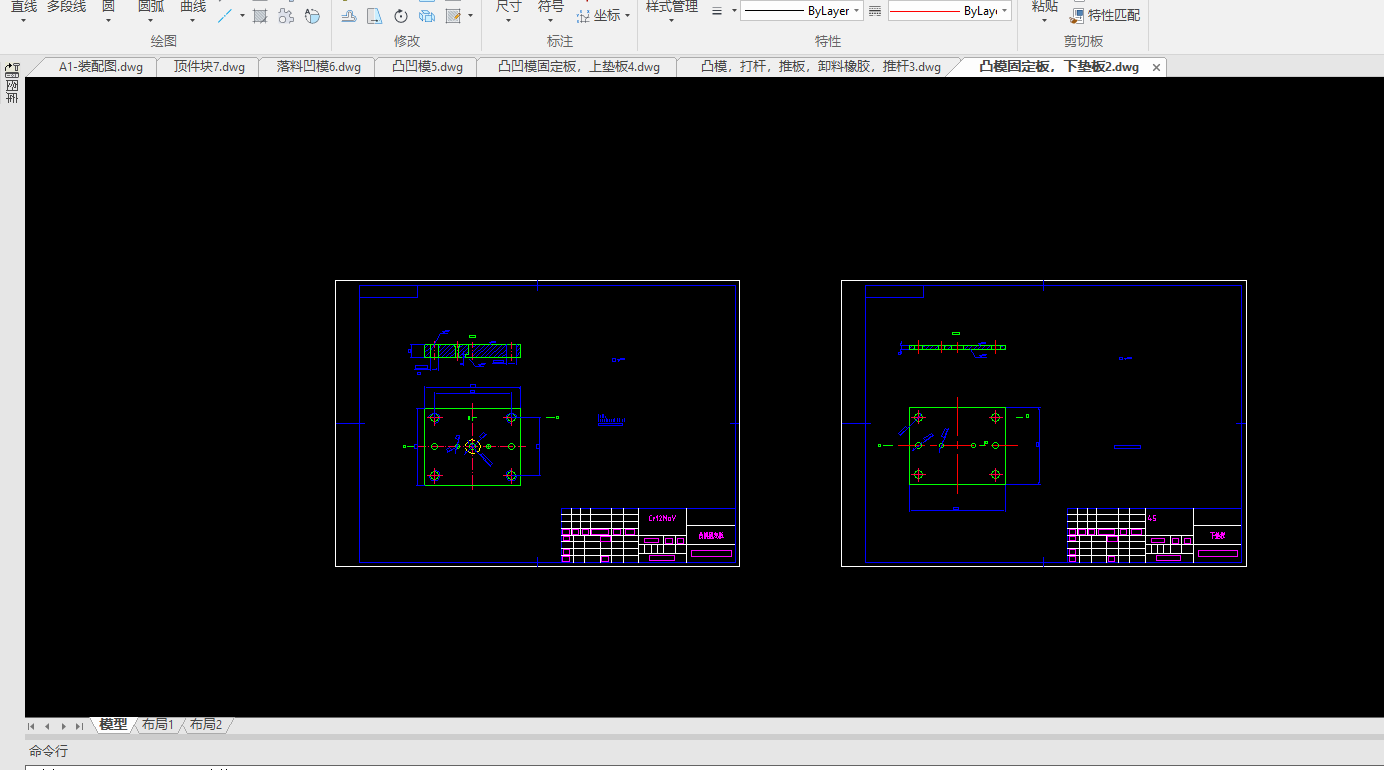

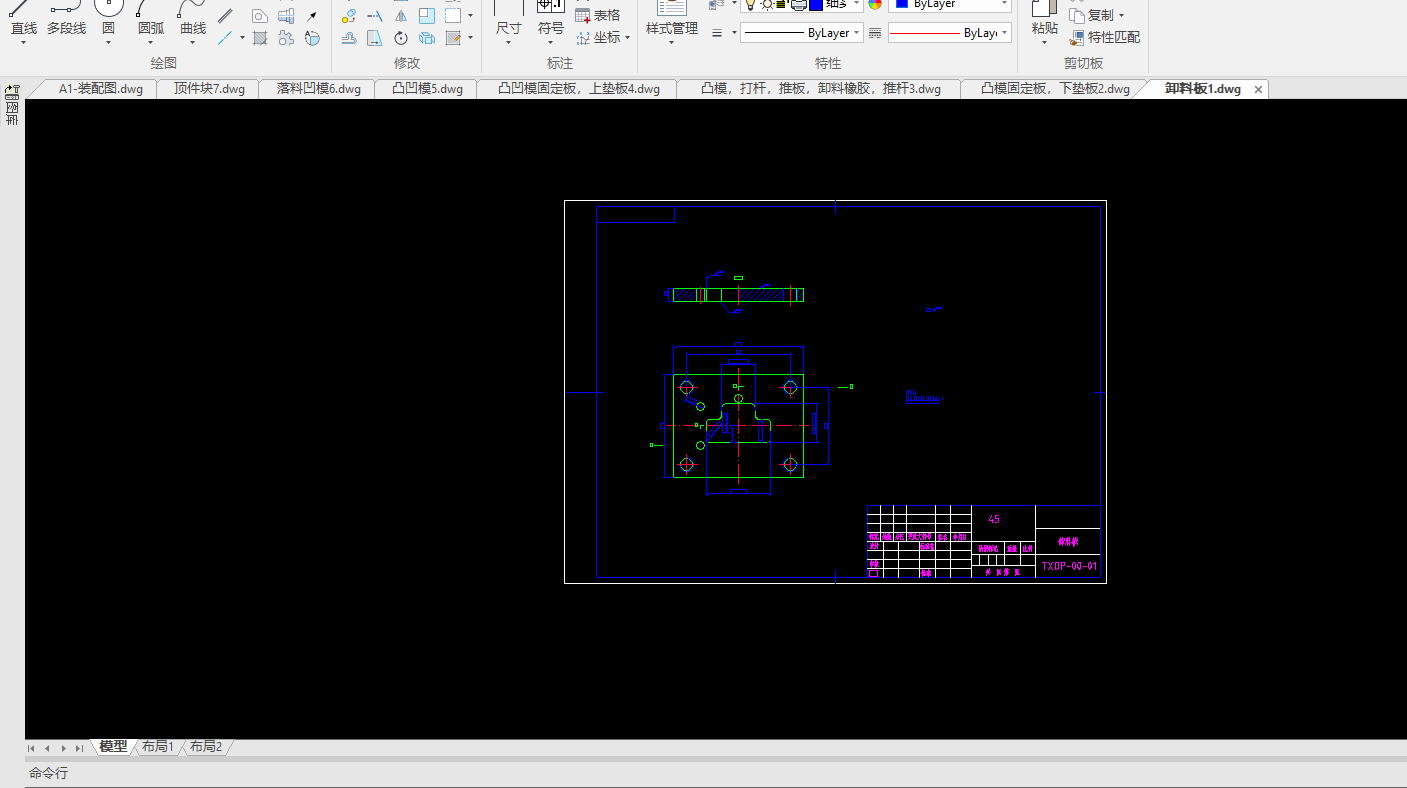

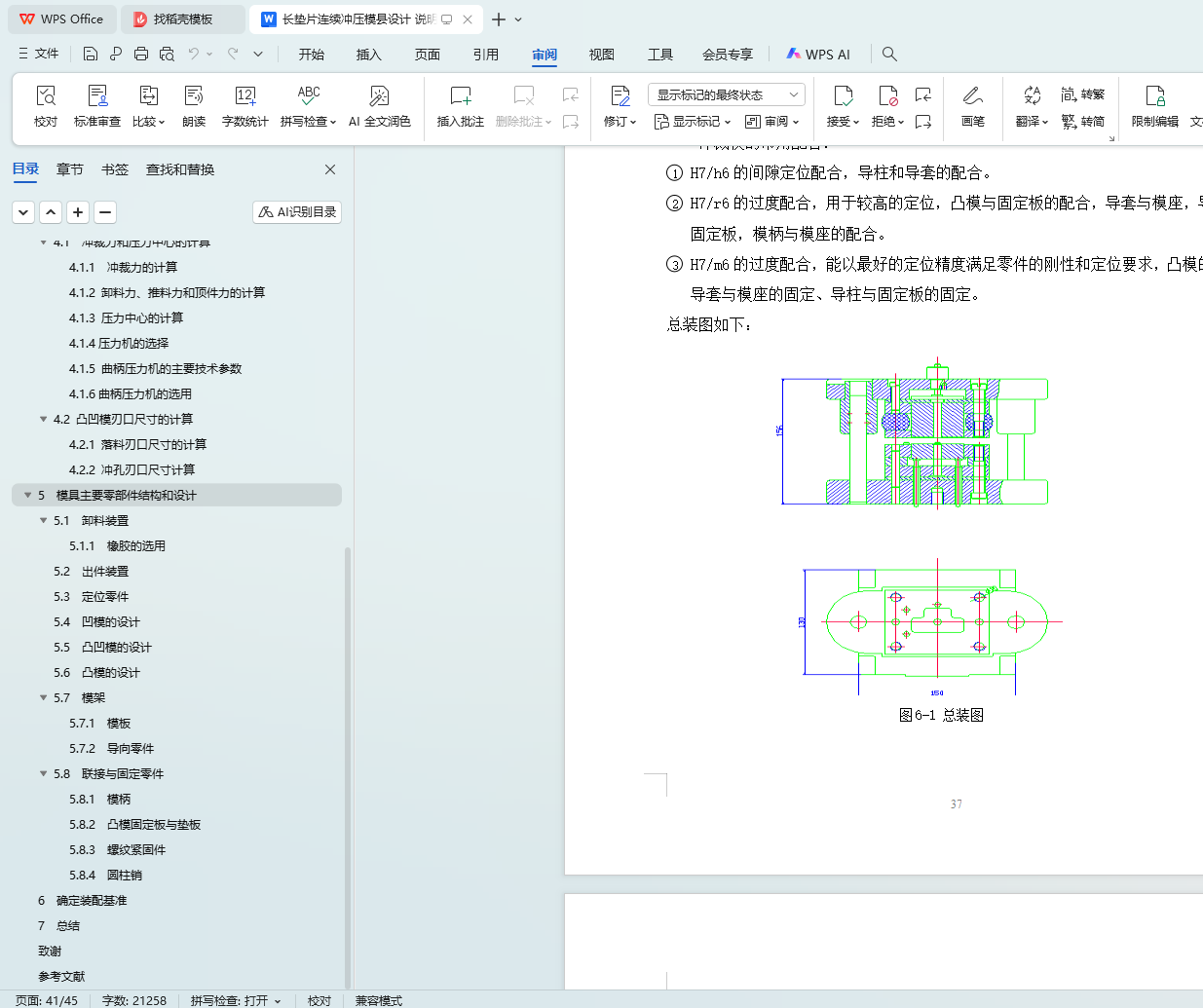

在模具主要零部件的结构与设计中,本设计重点考虑了卸料装置、出件装置、定位零件、凹模、凸凹模及凸模等关键部件的设计与优化。通过选用高性能的材料与先进的制造工艺,确保了模具的耐用性与精度。同时,还设计了合理的模架结构,包括模板与导向零件等,以确保模具的稳定运行与高效生产。

最终,本设计实现了长垫片的连续冲压生产,有效提高了生产效率与产品质量。此外,本设计还考虑了模具的装配基准与后续维护,为模具的长期稳定运行提供了保障。

关键词:长垫片;连续冲压;模具设计;冲裁工艺;生产效率

Abstract

As a common joint and sealing element in the industrial field, the long gasket is in increasing demand. In order to improve production efficiency and product quality, this design studies and develops the continuous stamping die of long pad. As an efficient and accurate metal processing method, stamping plays an important role in machinery, automobile, electronics and other industries. The design of continuous stamping die of long gasket aims to realize the efficient, automatic and high precision production of long gasket by optimizing the die structure and process parameters.

This design first analyzes the material characteristics and structural process of long gas, and determines the appropriate stamping process scheme. In the sample design, the production cost is effectively reduced through reasonable sample layout and material utilization calculation. Then, the detailed cutting process calculation, including the punching force, pressure center and blade size, provides a scientific basis for the design and manufacture of the die.

In the structure and design of the main parts of the mold, the design focuses on the design and optimization of the key parts such as unloading device, output device, positioning parts, concave mold, convex concave mold and convex mold. By selecting high performance materials and advanced manufacturing technology, to ensure the durability and accuracy of the die. At the same time, a reasonable mold frame structure, including formwork and guide parts, is also designed to ensure the stable operation and efficient production of the mold.

Finally, the design realizes the continuous stamping production of long gasket, which effectively improves the production efficiency and product quality. In addition, the design also considers the assembly benchmark and subsequent maintenance of the mold, which provides a guarantee for the long-term stable operation of the mold.

Key words: long gasket; continuous stamping; mold design; cutting process; production efficiency

目 录