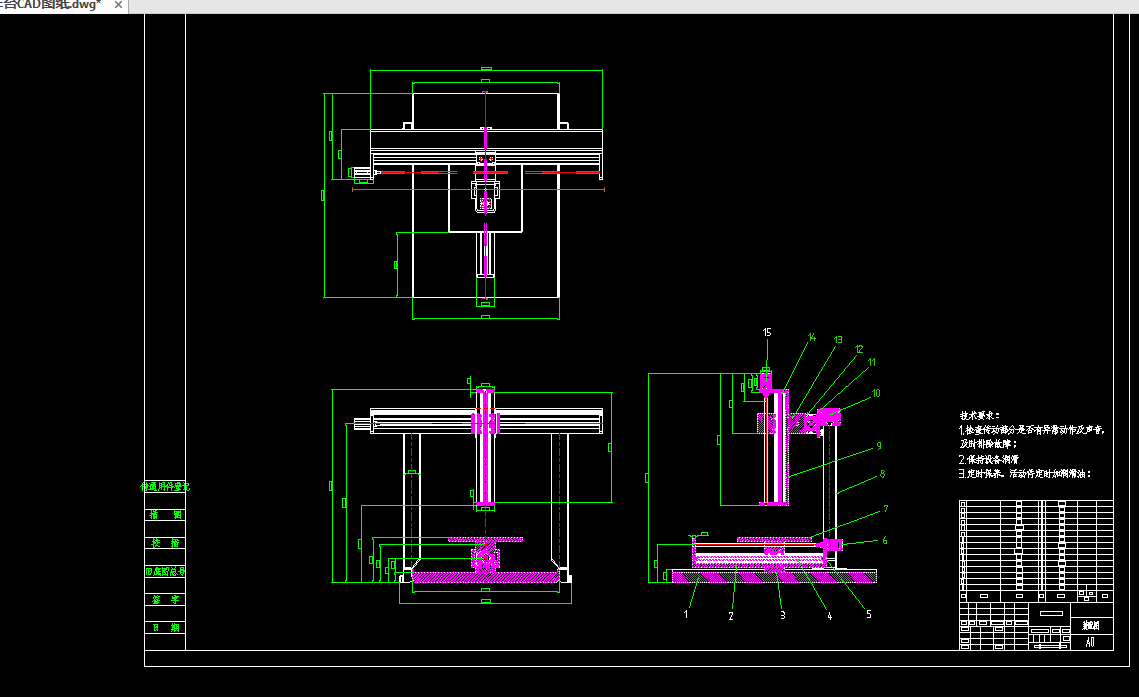

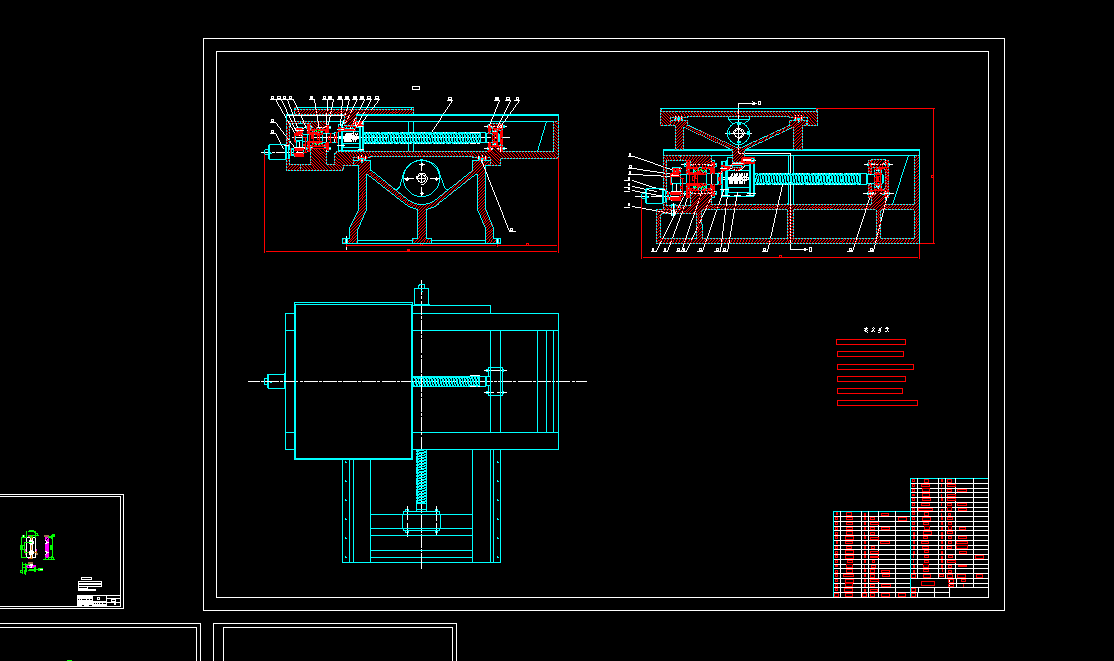

视觉检测工作台设计 说明书(论文)+任务书+CAD图纸+UG三维图

摘 要

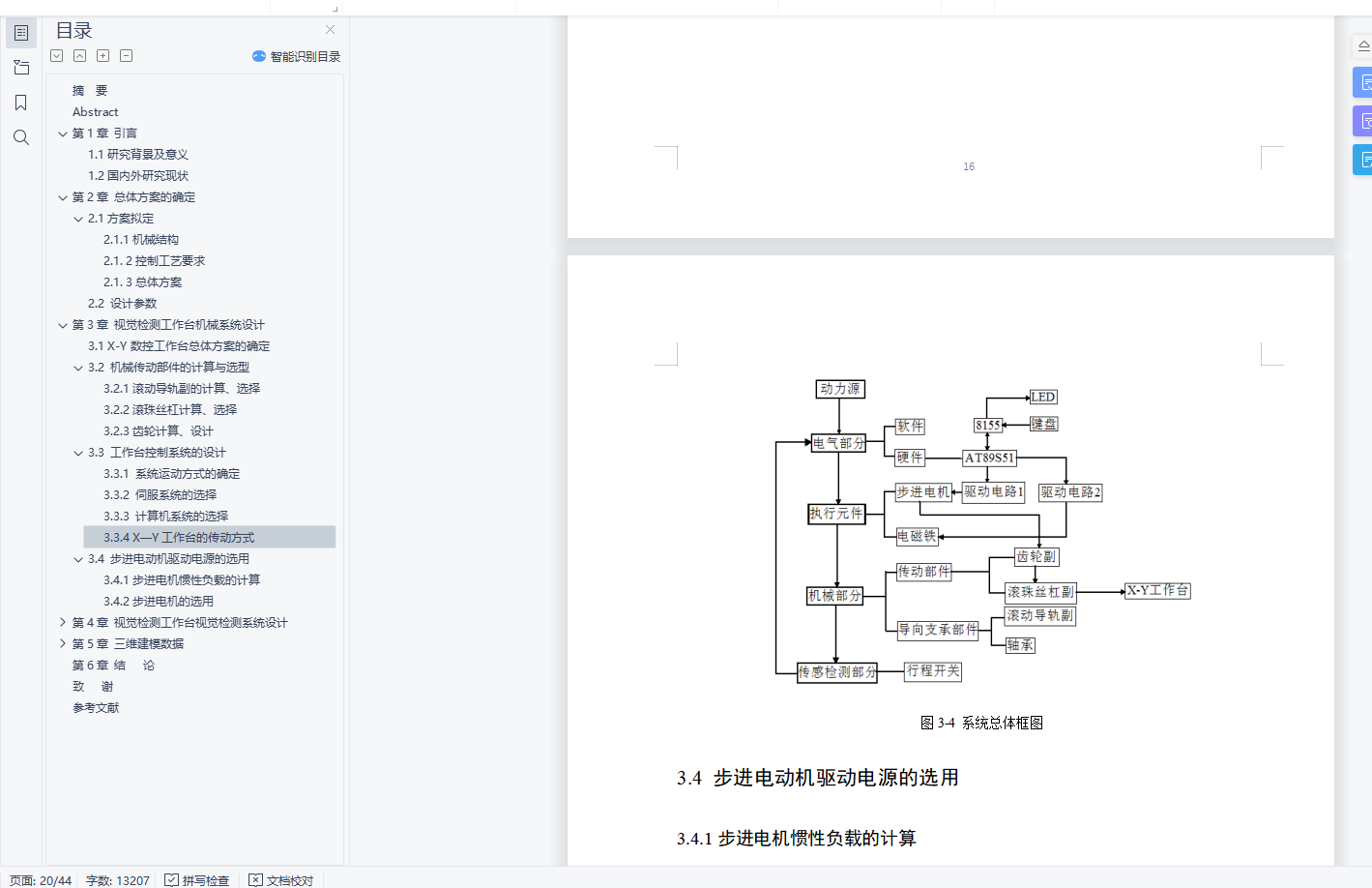

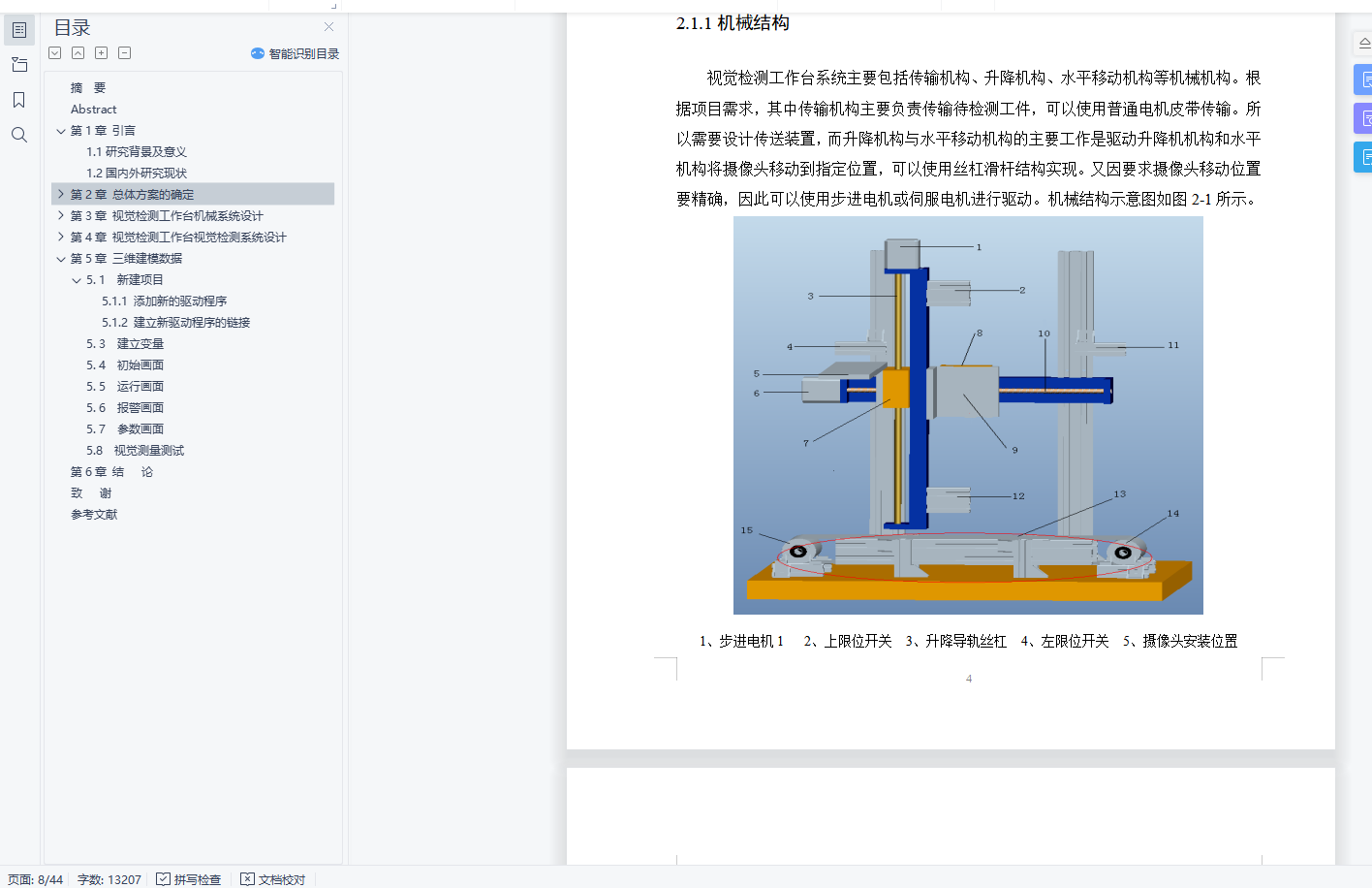

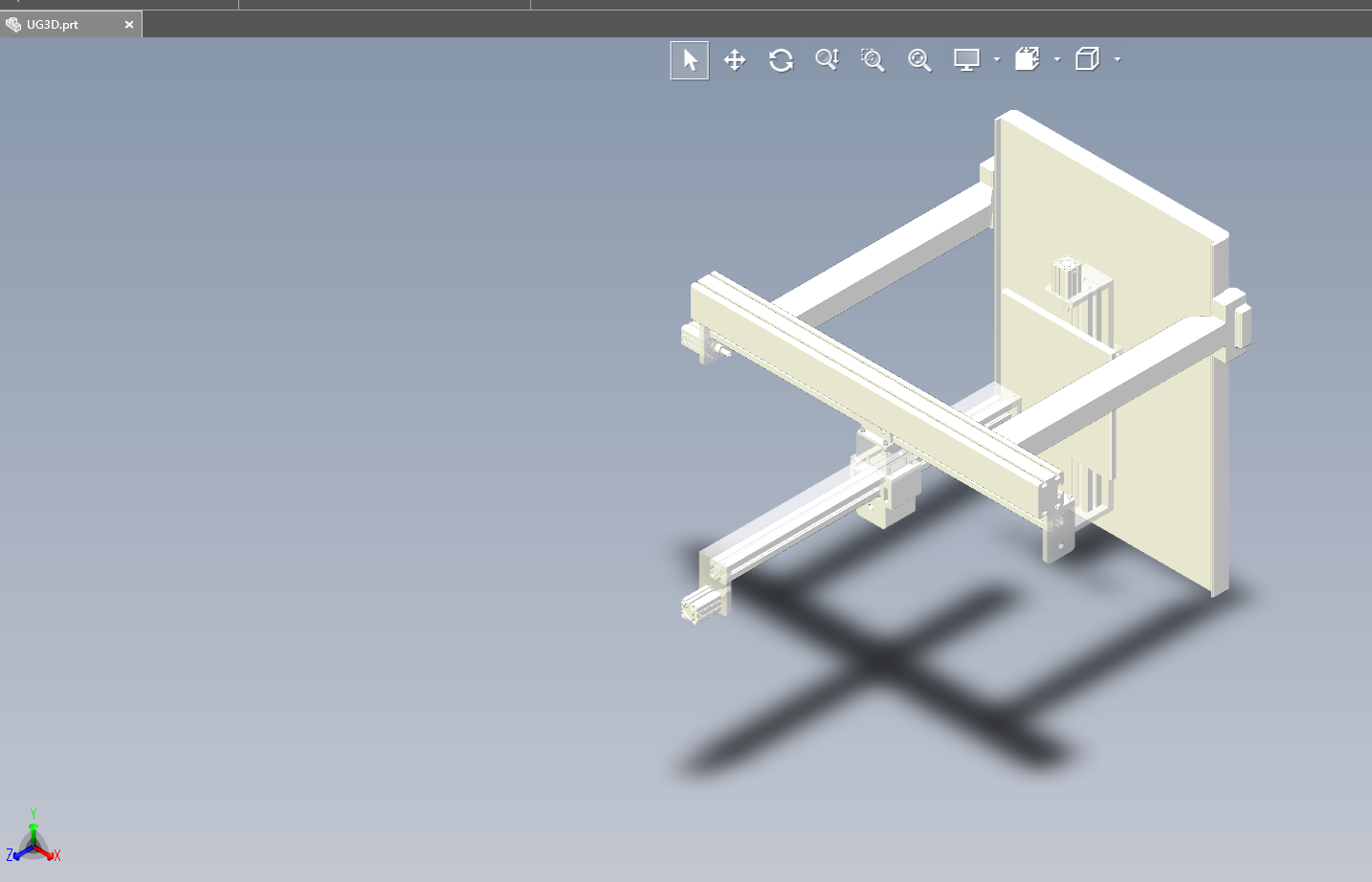

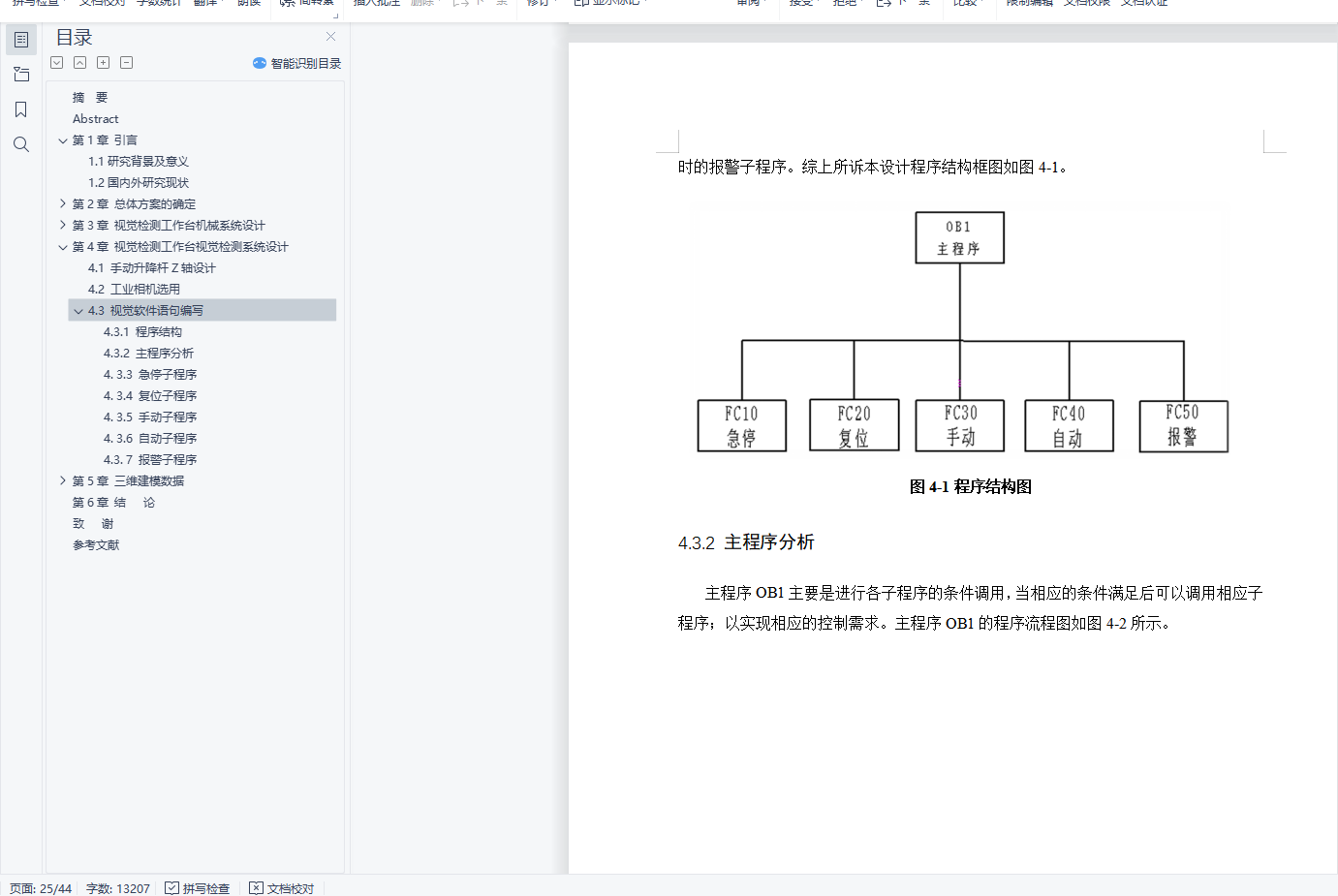

为了数字图像采集工作台在X-Y方向能够实现自动控制,完成被测试件的准确定位;并能实现摄像头的准确对焦。本文根据实际工业生产需求叙述怎样进行机械系统设计、部件选型与视觉系统的设计,机械系统设计主要为X-Y数控工作台的设计选型,包括传动部件、控制系统与步进电机的选用;视觉系统设计主要包括工业相机选用及视觉软件语句编写。

数字图像采集工作台在X-Y方向能够实现自动控制,完成被测试件的准确定位;Z轴方向能够上下移动,实现摄像头的准确对焦。为了提高机器视觉检测系统中摄像头的定位精度和实现摄像头的全自动调节,本文结合实际工业生产需求详细叙述了怎样进行机械机构设计、硬件选型与硬件接线以及精度计算设计等工作。其中硬件设计包含怎么选择合适的控制器、控制工艺、驱动设备、上位监控软件及网络通信方式等机器视觉检测台自动控制系统中的重要组成部分;精度计算设计主是指通过计算步进电机步距角与其高速脉冲频率的关系来实现摄像头移动位置的精确定位。

关键词:机器视觉;视觉检测;X-Y工作台;控制系统

Abstract

For the digital image acquisition workbench to realize automatic control in the X-Y direction, to complete the accurate positioning of the tested parts, and to realize the accurate focusing of the camera. According to the actual demand of industrial production, this paper describes how to design mechanical system, component selection and visual system. The design of mechanical system is mainly for the design and selection of X-Y NC workbench, including transmission parts, control system and step motor. Visual system design mainly includes industrial camera selection and visual software statement writing.

The digital image acquisition table can realize automatic control in the X-Y direction, complete the accurate positioning of the tested parts, and move up and down in the Z axis direction to realize the accurate focusing of the camera. In order to improve the positioning accuracy of the camera in the machine vision detection system and realize the automatic adjustment of the camera, this paper describes in detail how to design the mechanical mechanism, select the hardware and connect the hardware, and calculate the precision according to the actual industrial production requirements. The hardware design includes an important part of the automatic control system of machine vision detector, such as how to select the appropriate controller, control technology, driving equipment, upper monitoring software and network communication mode, etc. The precision calculation design mainly refers to the accurate location of the camera moving position by calculating the relationship between the step distance angle of stepping motor and its high speed pulse frequency.

Keywords: machine vision; visual detection; X-Y workbench; control system

目 录