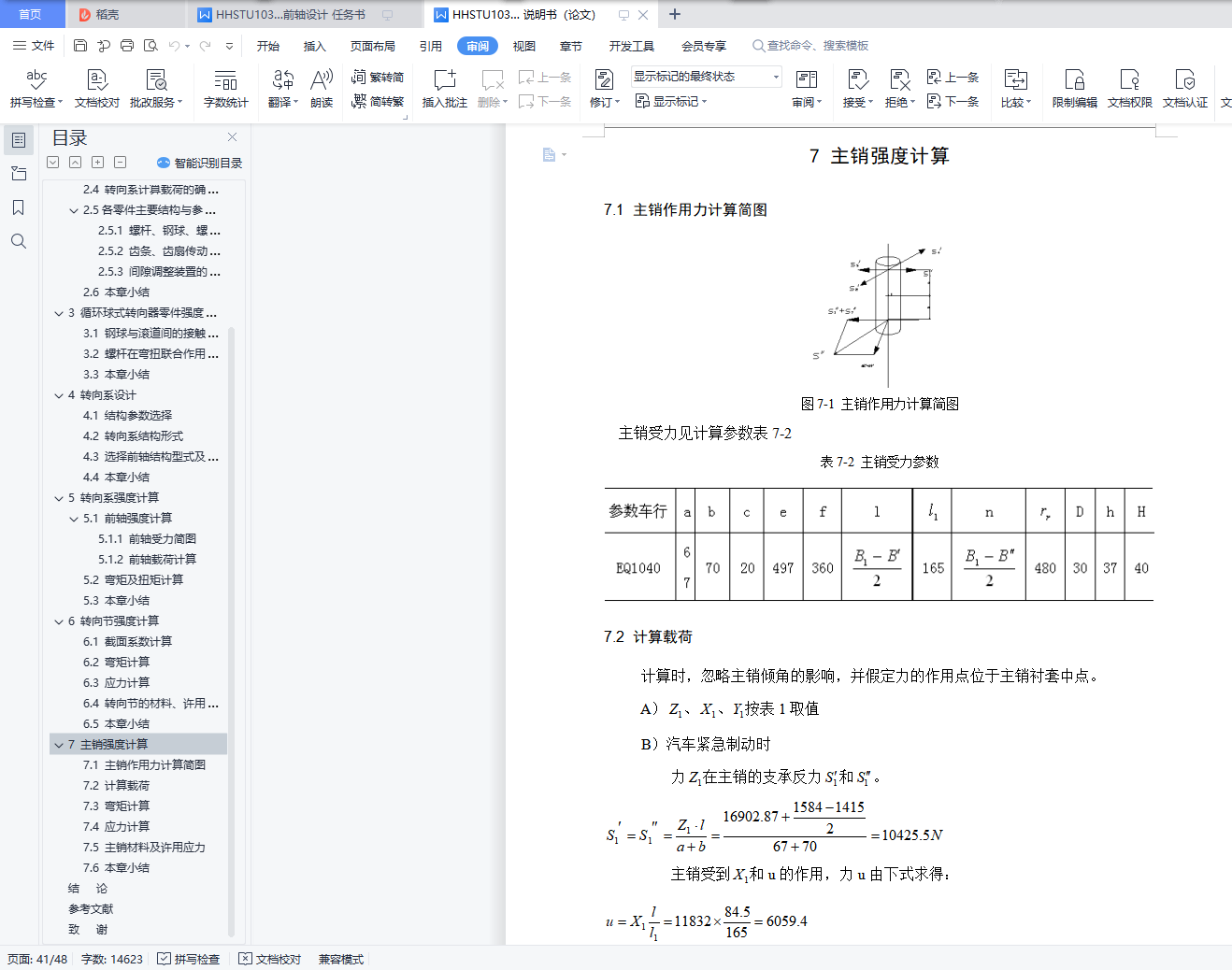

HHSTU1035型货车转向系及前轴设计 说明书(论文)+任务书+cad图纸

HHSTU1035型货车转向系及前轴设计

摘 要

近年来,我国国民经济不断发展,公路建设不断发展,促使物流业和运营业不断发展壮大,借此机会,载货汽车社会保有量不断增加,汽车操纵安全性成为一个重要研究课题,转向系统作为汽车几大重要系统之一,它的性能体现了整车操纵安全性的水平,因此,研究如何改进设计现有载货汽车的转向系统成为一个重要课题. 汽车转向系统在汽车设计中占据重要的地位,汽车转向系统性能的优劣影响着汽车的操纵性和稳定性,直接关系到汽车设计的成败.在设计汽车转向系统时,为使汽车的每个轮胎均产生纯滚动,理论上汽车的每个轮胎的轴线应交于一点,转向连杆机构即为实现这一功能而设计的。

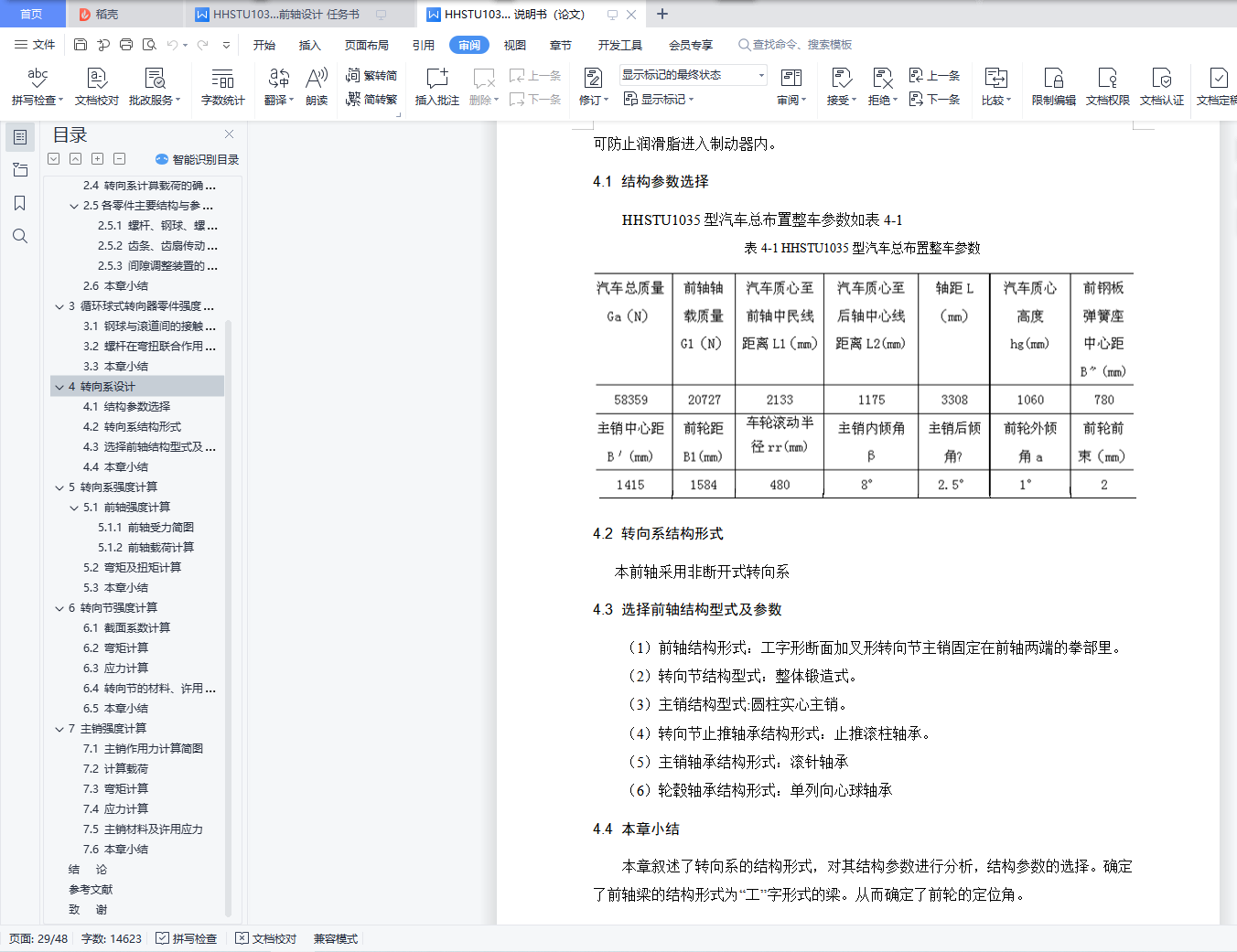

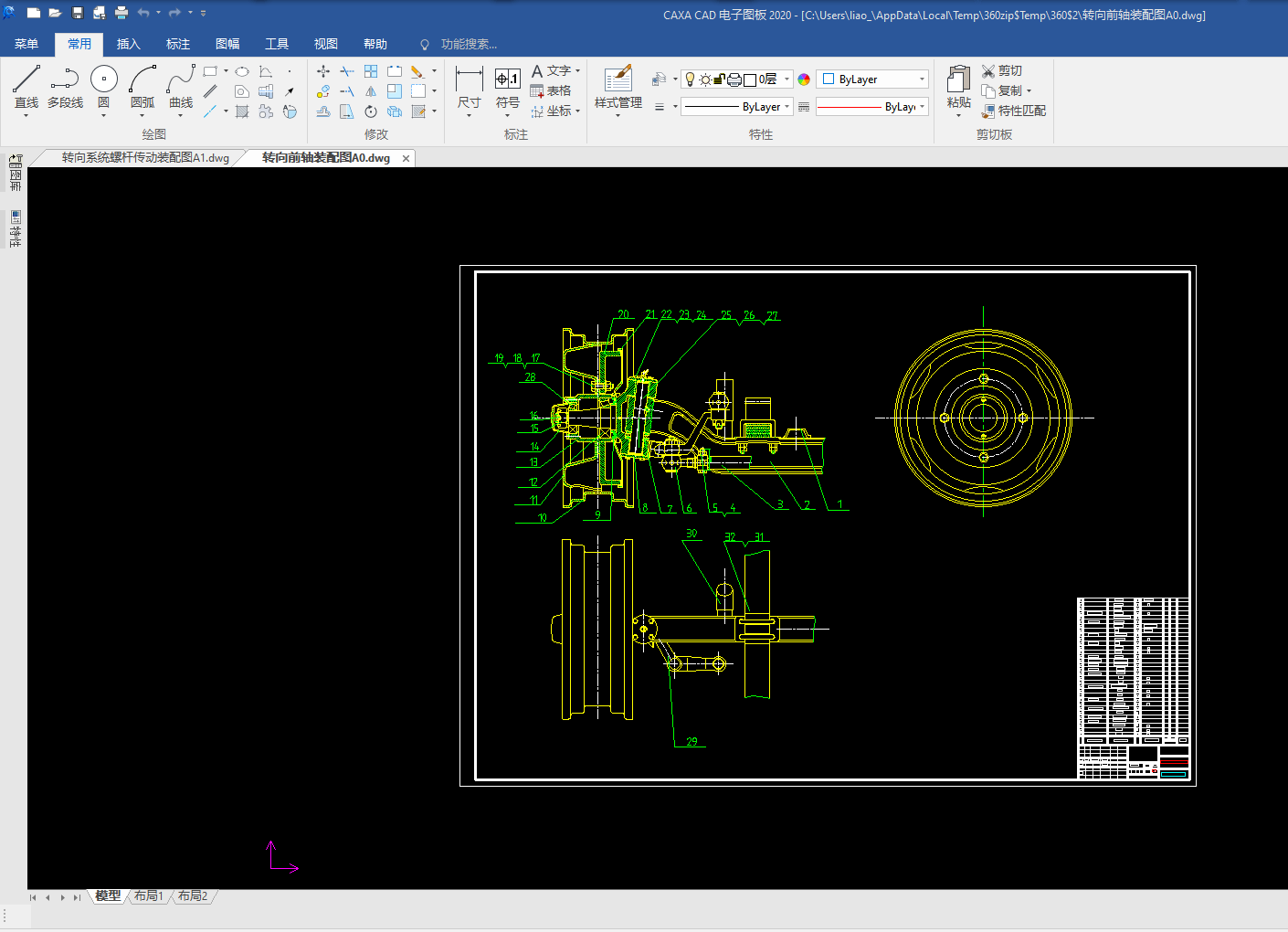

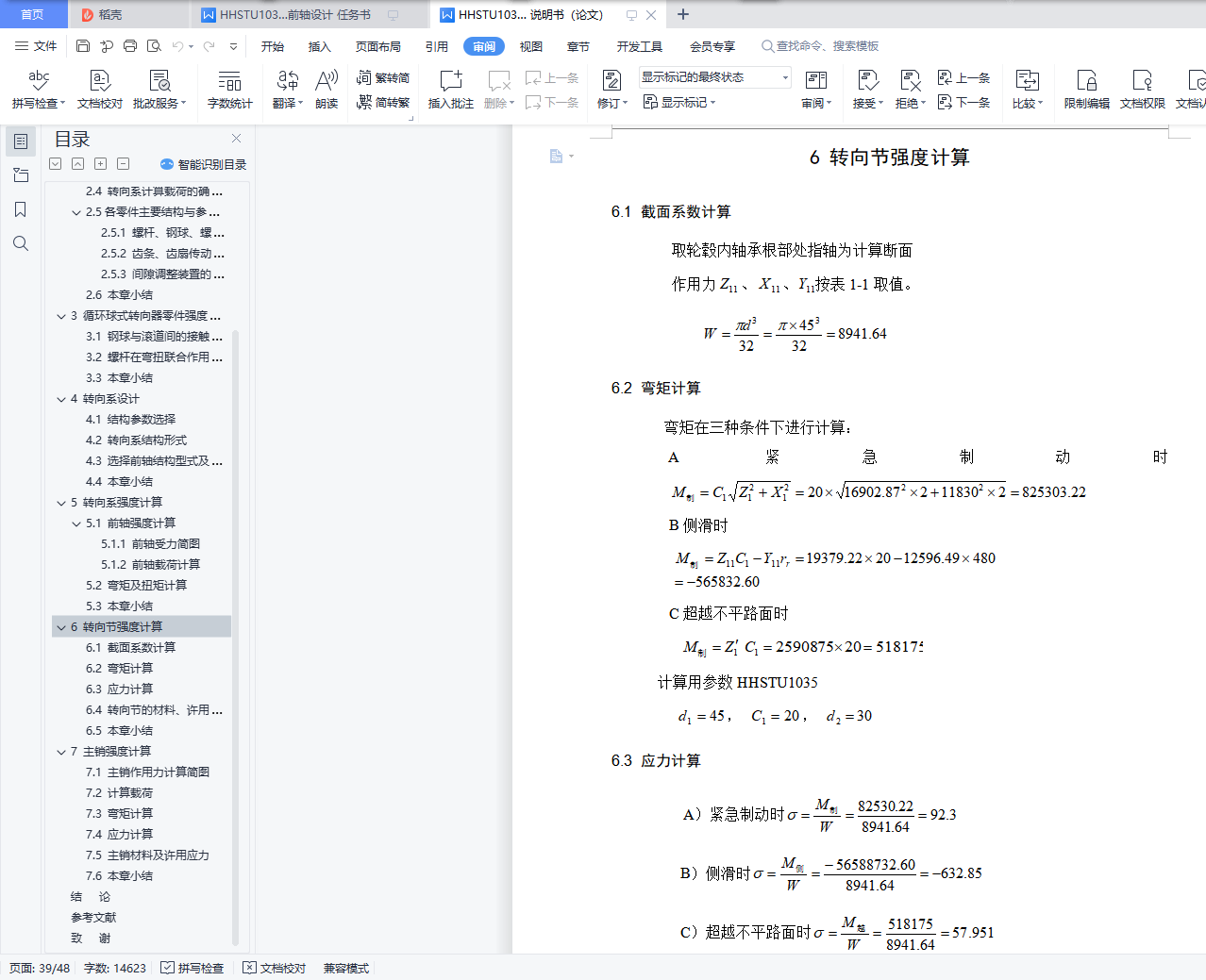

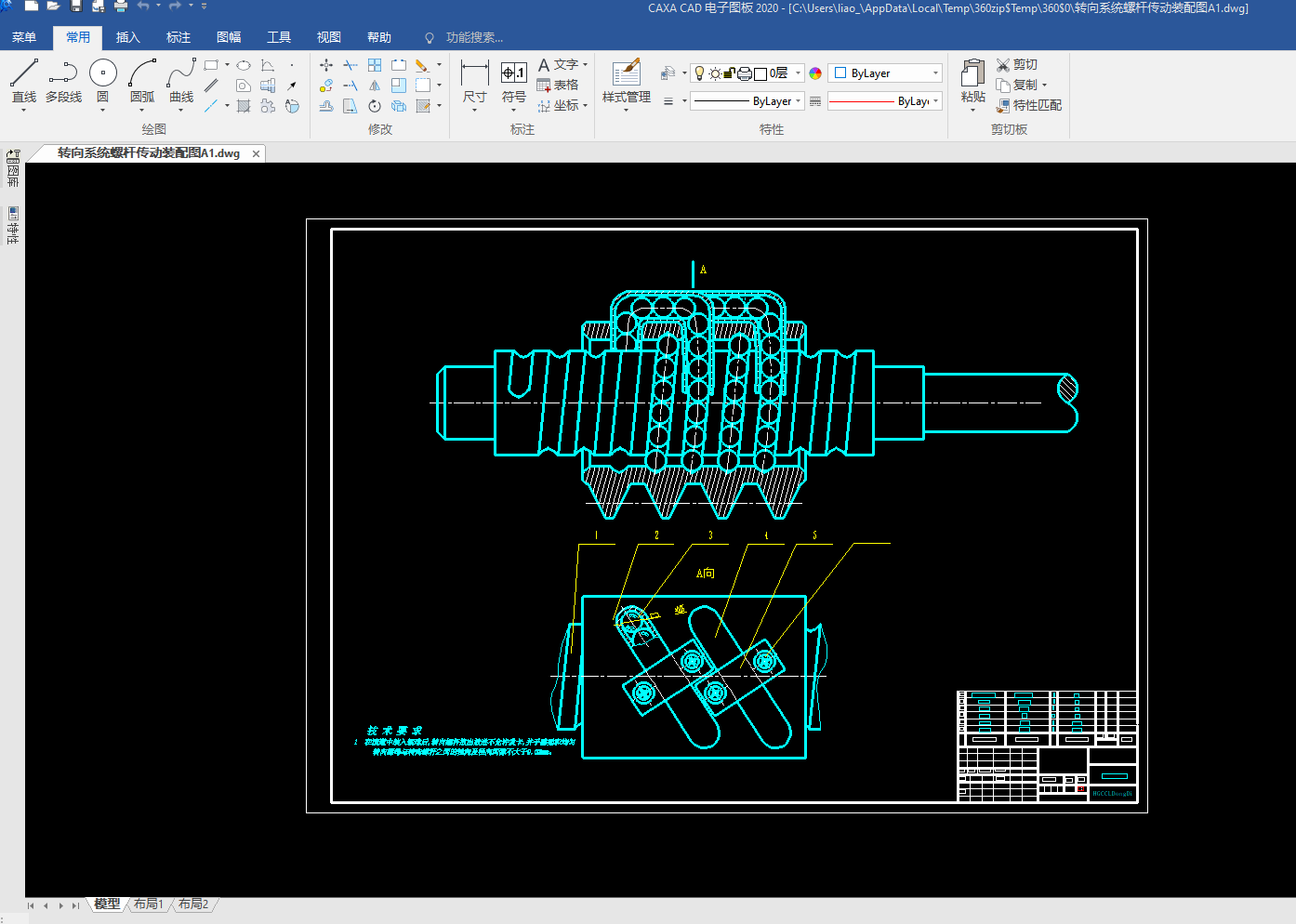

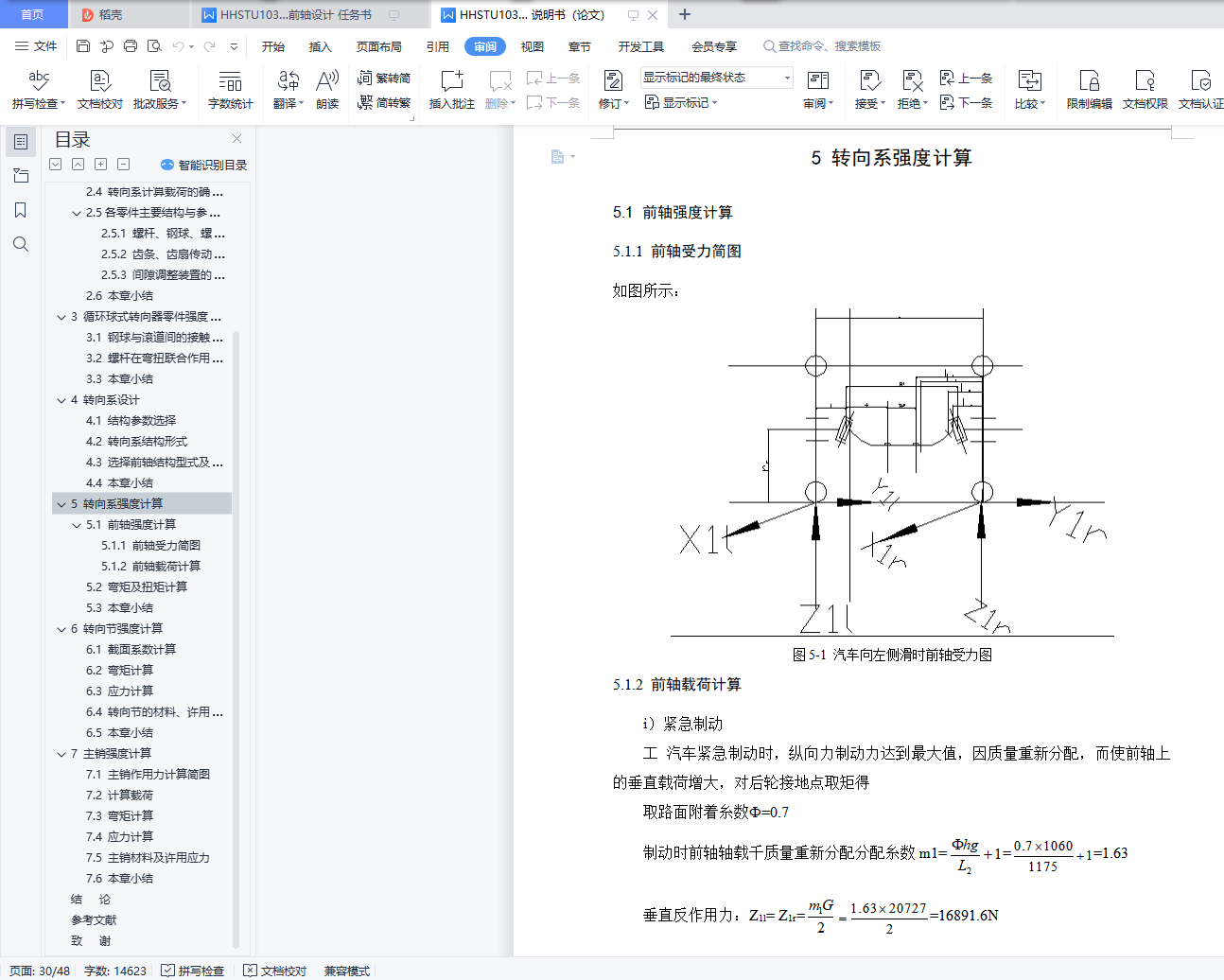

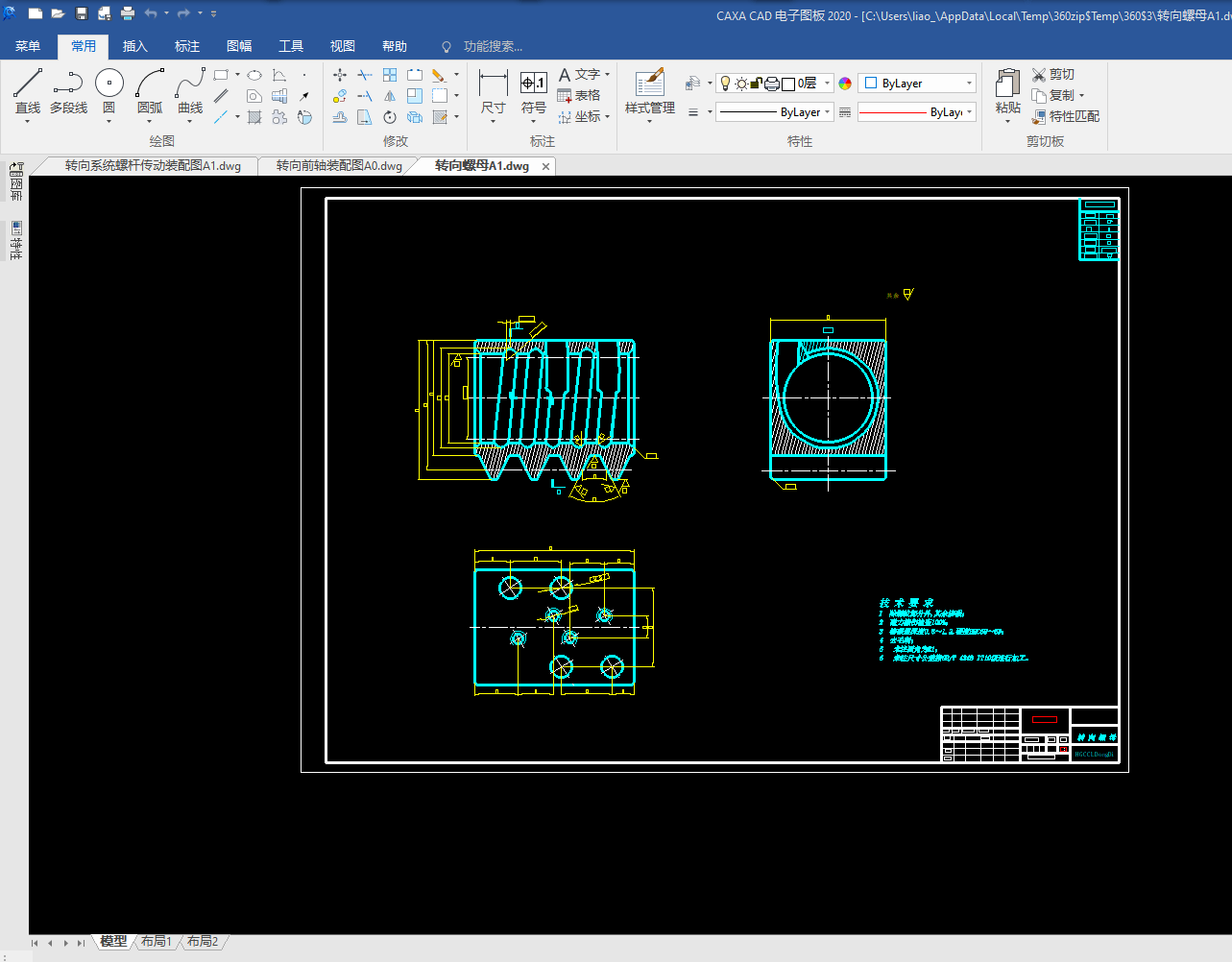

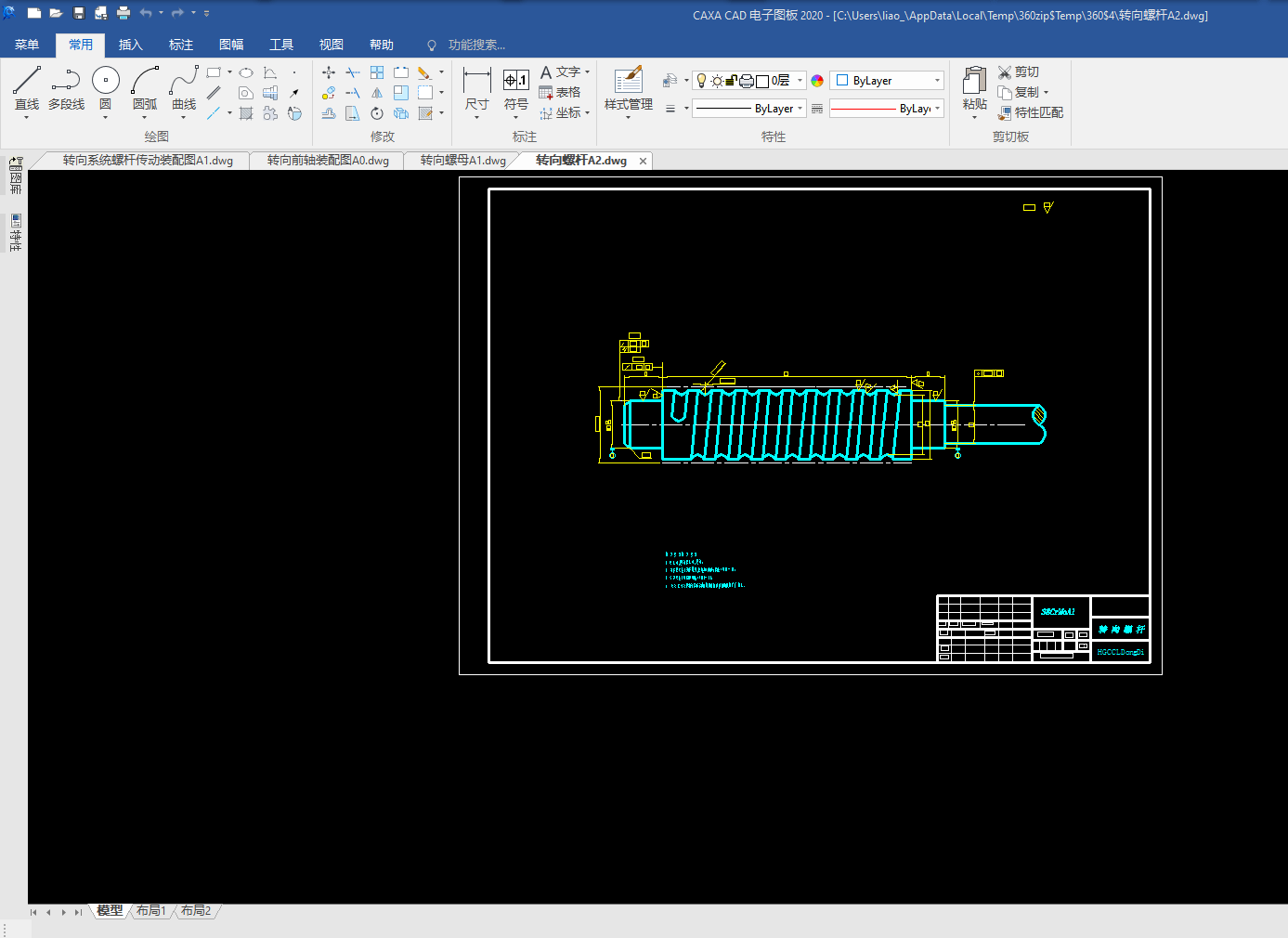

本次设计针对HHSTU1035型4×2载货汽车的开发,进行转向系及前轴设计。为了确保转向系统性能,进行运动校核和干涉校核。同时整个转向系统安全性要求很高,所以必须保证关键零部件的强度满足使用要求,本文对转向垂臂和直拉杆进行了强度校核。

关键词:载货汽车;转向系;前轴;载荷;强度

Design of steering system and front axle for HHSTU1035 truck

ABSTRACT

In recent years, the development of our national economy and highway construction has promoted the development of logistics industry and operation industry. As one of the most important systems, steering system shows the level of vehicle handling safety. Therefore, it is an important subject to study how to improve the steering system of the existing truck. Automobile steering system plays an important role in automobile design. The performance of automobile steering system affects the maneuverability and stability of automobile, which is directly related to the success or failure of automobile design. In the design of automobile steering system, in order to make every tire of automobile produce pure rolling, the axis of each tire of automobile should be intersected at one point in theory, and the steering linkage mechanism is designed to realize this function.

This design aims at the development of HHSTU1035 4×2 truck, steering system and front axle design. In order to ensure the performance of steering system, motion check and interference check are carried out. At the same time, the safety requirement of the whole steering system is very high, so it is necessary to ensure that the strength of the key parts meets the requirements of use. In this paper, the strength of the steering vertical arm and the straight pull rod is checked.

Keywords: truck; steering system; front axle; load; strength

目 录