汽车前门外板逆向设计论文+任务书+开题+文献综述

摘 要

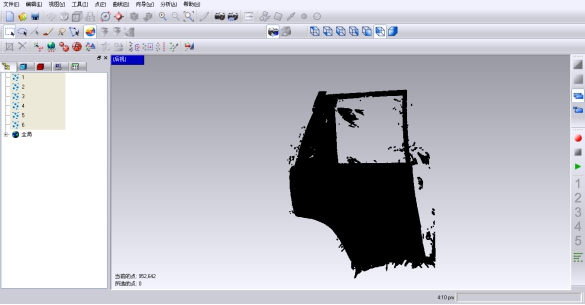

基于CATIA软件的 “数字化外形编辑器”模块可以快速、方便地对测量点云进行处理,勾勒出零件原型的轮廓特征线。“快速曲面重建”模块可以在点云上建立并处理特征线,拟合出满足一定要求的曲面,“创成式曲面设计”模块可以在已建立的轮廓特征线及基本曲面上进一步进行处理,生成更高质量的曲面。从而完成汽车前门外板的逆向设计。车门作为一个综合的转动部件和车厢一起构成了乘员舱的空间界面,设计的车门应具有足够大的强度、刚度和良好的振动特性,以满足车门闭合时耐冲击性及与侧碰时的耐撞性等各项性能的要求。本设计在参考了多种车门结构形式的基础上,具体设计了一个分体式前车门。

本设计说明书主要介绍以CATIA软件为设计平台,运用逆向工程方法完成汽车前门外板逆向设计,并对该零部件制造工艺分析。由数据采集、数据处理、逆向设计,三大部分对该零部件CAD模型构建。在设计过程中涉及到:基于studio点云的过滤、点云整理,然后对点云进行网格化;利用CATIA曲面重构,主要利用3D曲线和扫描线等命令编辑车门轮廓,利用曲面拟合和多截面曲面命令生成曲面。Studio点云处理功能强大,CATIA在曲面的处理上具有更强的优势。对于复杂的曲面,通过Studio和CATIA软件结合,可以达到更好的建模效果。在建模过程中,运用正逆向设计的思维,多种方法对汽车前门外板3D建模,并进行精度比较,最后选取本次设计方法。

关键词:分体式;轿车前车门外板;逆向设计

Abstract

The "Digital shape Editor" module based on CATIA software can process the measurement point cloud quickly and conveniently, and draw out the contour feature line of the part prototype. The "fast surface reconstruction" module can set up and process the feature lines on the point cloud and fit the surfaces that meet certain requirements. The "creating surface design" module can be further processed on the established contour feature lines and basic surfaces. Creates higher quality surfaces. In order to complete the reverse design of the outer panel of the front door of the automobile. The door, as an integrated rotating component, together with the car, constitutes the space interface of the cabin. The design of the door should be of sufficient strength. , stiffness and good vibration characteristics to meet the requirements of impact resistance of door closure and impact resistance with side impact. On the basis of referring to many kinds of door structure, a separate front door is designed.

This design specification mainly introduces the reverse design of the outer panel of the front door of the automobile based on the CATIA software and the analysis of the manufacturing process of the parts. Data acquisition, data processing, reverse design, three parts of the part of the CAD model construction. In the process of design, it involves: filtering point cloud based on studio, sorting point cloud, then gridding point cloud, reconstructing CATIA surface, editing the outline of door by using 3D curve and scanning line, etc. Using surface fitting and multi-section curved surface command to generate surface. Studio point cloud processing function is powerful. ATIA has more advantages in surface processing. For complex surfaces, a better modeling effect can be achieved through the combination of Studio and CATIA software. In the process of modeling, using the thinking of positive and reverse design, many methods are used to model the front door outer panel 3D, and the precision is compared. Finally, this design method is selected.

Keywords : split type ;Car front door outer panel ;reverse design

目 录