发动机仓盖内板逆向设计毕业论文+开题+文综+三维图+检测报告

摘 要

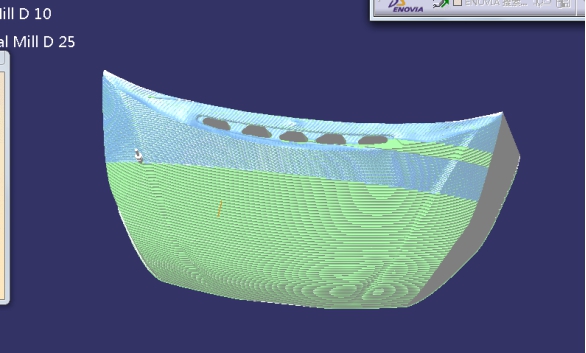

本文主要介绍了基于CATIA软件将汽车发动机仓盖内板数据点云通过逆向工程技术设计成零件实体的过程,以及其数控模拟加工。在设计过程中涉及到点云整理、数字编辑、自由曲面造型、快速曲面造型等技术。在建模过程中,遇到桥接出现错误、拼接无法完成等问题,都得到了较好的解决。

在具体逆向设计中,为了建好曲面模型,运用了不同的方案,经过多次的失败和改正后,最终获得了较好的曲面模型。

关键词:逆向工程;发动机仓盖内板;CATIA;曲面造型;

Abstract

This paper mainly introduces the process of designing the data point cloud of the inner plate of the automobile engine cover by reverse engineering technology based on CATIA software and its numerical control simulation machining. In the design process, point cloud finishing, digital editing, free surface modeling, fast surface modeling and other technologies are involved. In the process of modeling, the problems such as bridge error and splicing can not be completed have been solved well.

In the specific reverse design, in order to build the surface model, different schemes are applied. After many failures and corrections, a better surface model is obtained.

Keywords: reverse engineering; CATIA; Surface modeling;

目 录