车身横梁逆向设计毕业论文+任务书+文献综述

摘 要

汽车车身横梁用热轧钢板是载重汽车应用最广泛的钢板之一,本文介绍了我国汽车车身横梁板的生产现状,消费现状,典型生产企业以及发展趋势。将车身横梁固定在经过失效处理过的基础架上,并放置在三坐标平台上调平,以前围、顶盖、后围、侧围的特征对称点为参考,将车身横梁调整在车身横梁坐标系下。

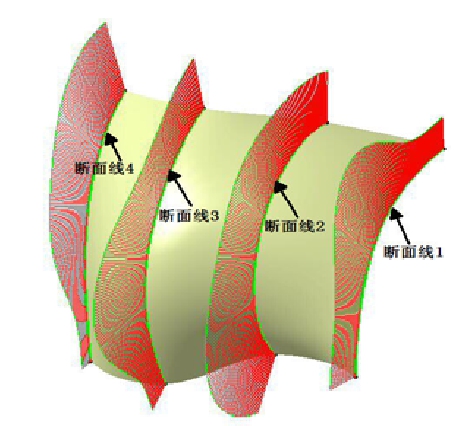

基于CATIA软件的 “数字化外形编辑器”模块可以快速、方便地对测量点云进行处理,勾勒出零件原型的轮廓特征线。“快速曲面重建”模块可以在点云上建立并处理特征线,拟合出满足一定要求的曲面,“创成式曲面设计”模块可以在已建立的轮廓特征线及基本曲面上进一步进行处理,生成更高质量的曲面。从而完成汽车车身横梁的逆向设计。

关键词:汽车车身横梁;逆向设计;性能

Abstract

Hot rolled steel plate for automobile body crossbeam is one of the most widely used steel plates for truck. This paper introduces the production status, consumption status, typical production enterprise and development trend of automobile body beam plate in China. The body beam is fixed on the foundation frame after the failure treatment, and is placed on the three coordinate platform with the characteristics of up-leveling, front girth, top cover, rear girth and side circumference as reference points, and the body crossbeam is adjusted in the body crossbeam coordinate system.

The "Digital shape Editor" module based on CATIA software can process the measurement point cloud quickly and conveniently, and draw out the contour feature line of the part prototype. The "fast surface reconstruction" module can set up and process the feature lines on the point cloud and fit the surfaces that meet certain requirements. The "creating surface design" module can be further processed on the established contour feature lines and basic surfaces. Creates higher quality surfaces. In order to complete the reverse design of the automobile body beam.

Key words: automobile body beam; reverse design; performance

目 录