100万ta钛铁矿选矿厂初步设计 毕业论文+外文翻译及原文

摘 要

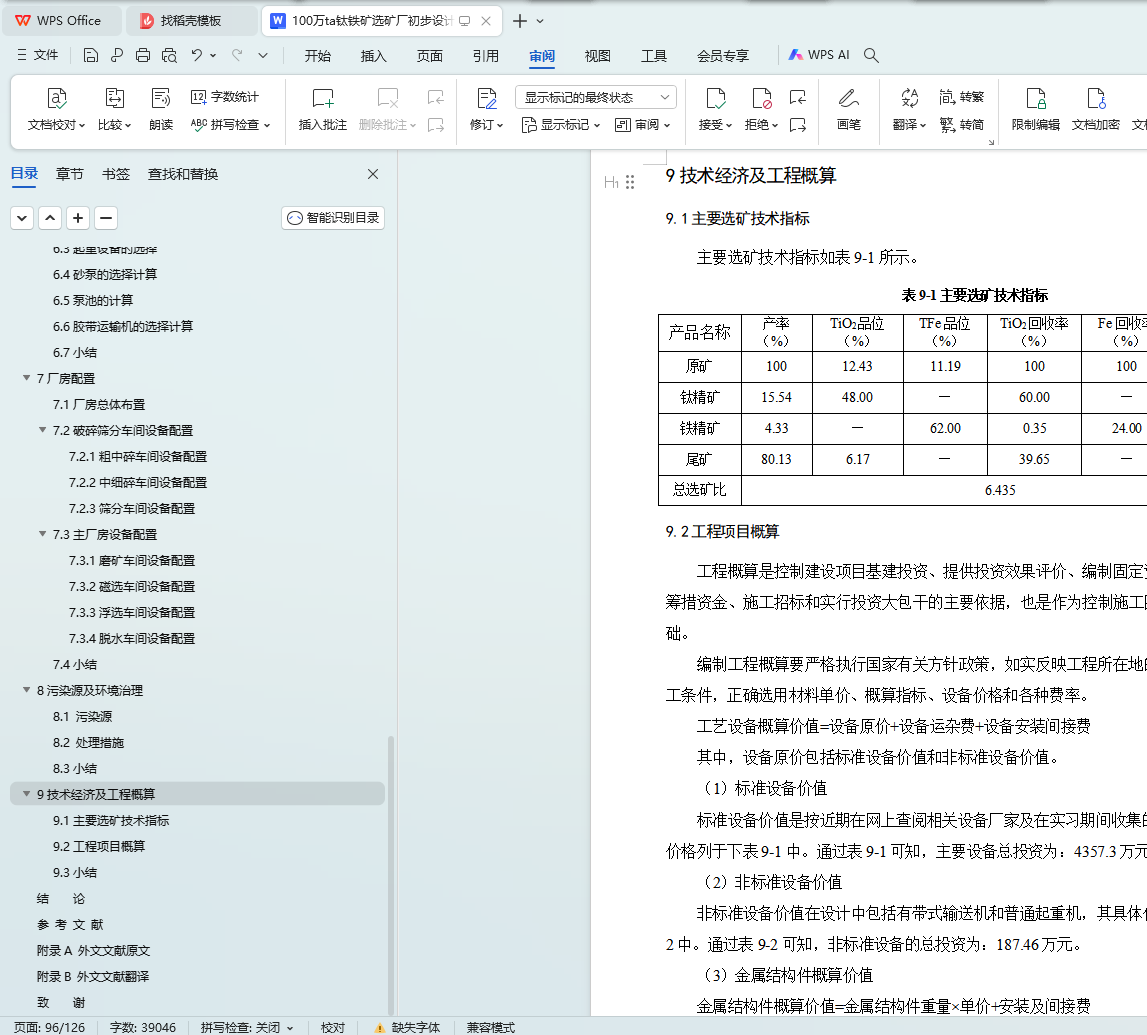

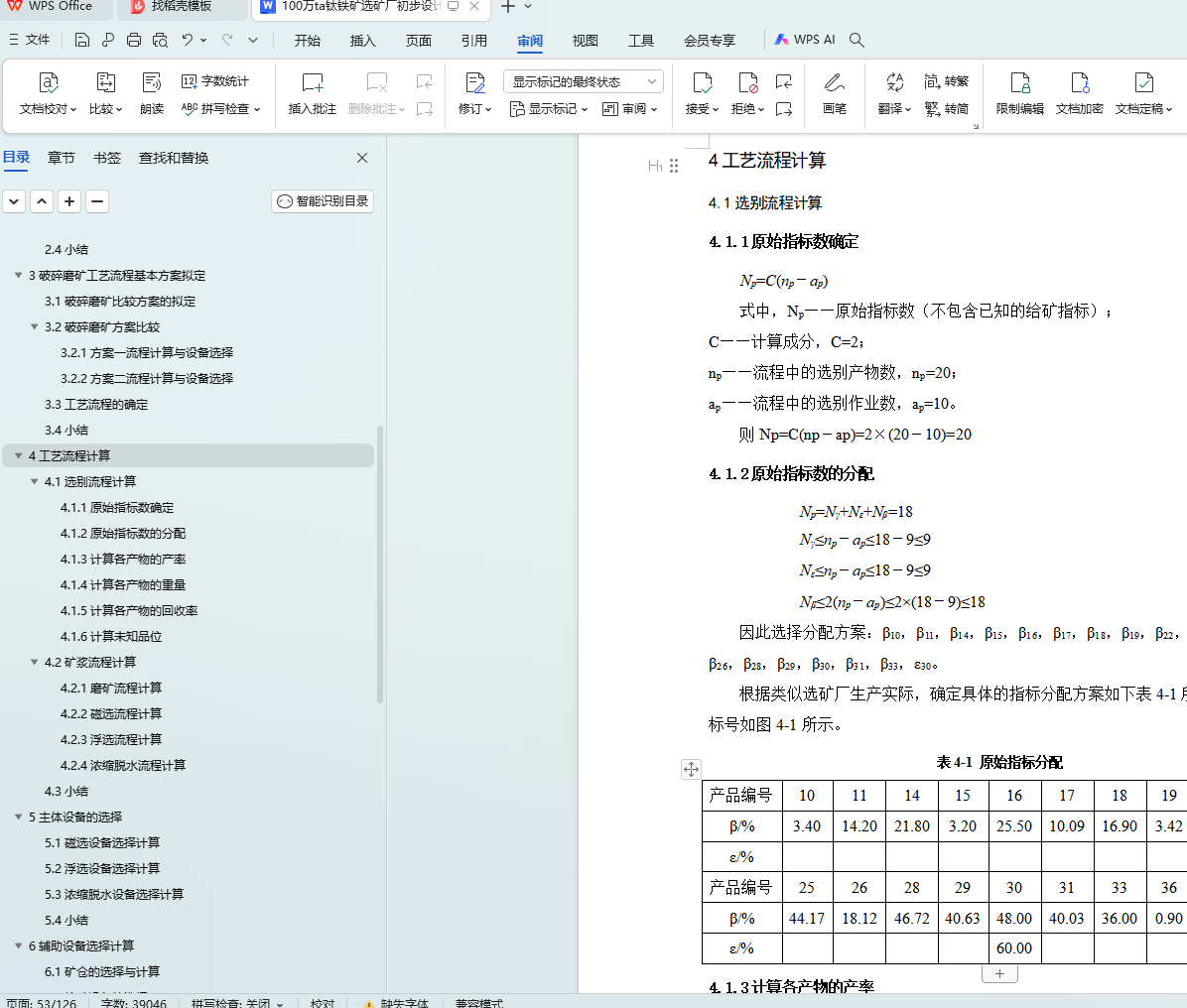

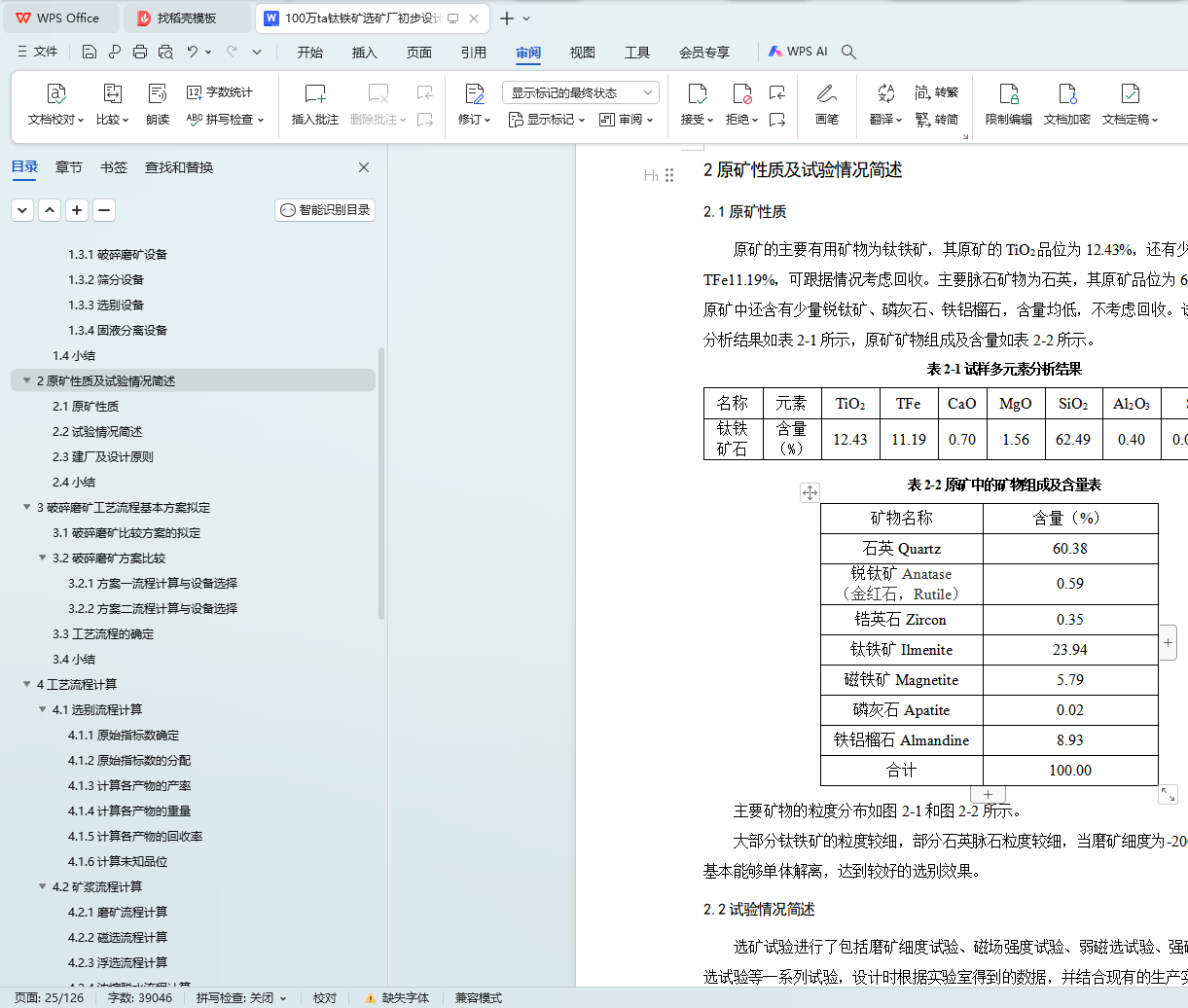

对年处理量100万吨的钛铁矿选矿厂进行了初步设计。原矿以钛铁矿为主要有用矿物,含有少量的磁铁矿,脉石矿物主要是石英。设计指标为最钛精矿TiO2品位不小于48.00%,回收率达到60.00%,铁精矿Fe品位不低于62.00%,其他杂质符合质量标准要求。

设计内容包括流程的选择与计算、设备的选型与计算、设备配置和厂房布置、简单的工程概算等。

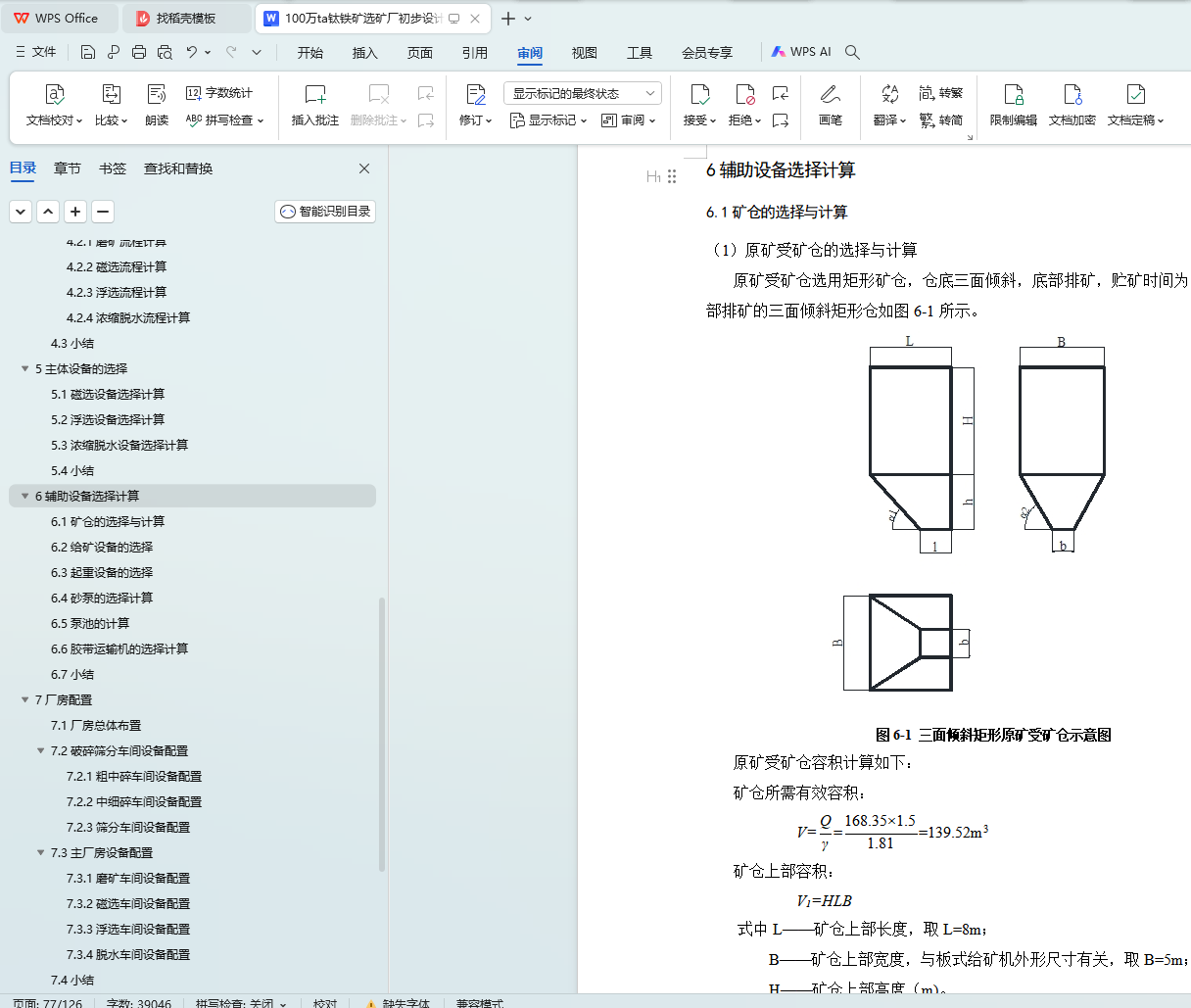

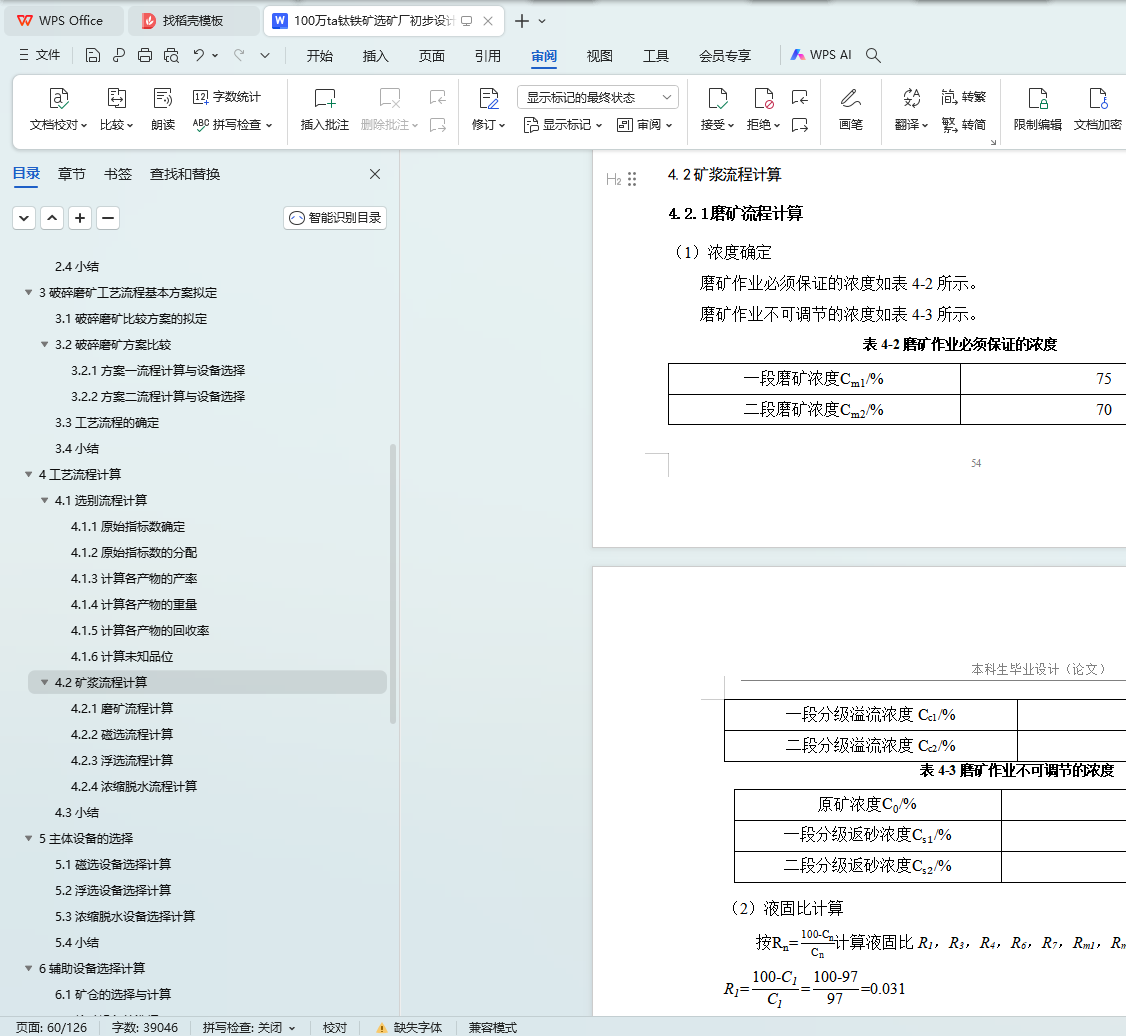

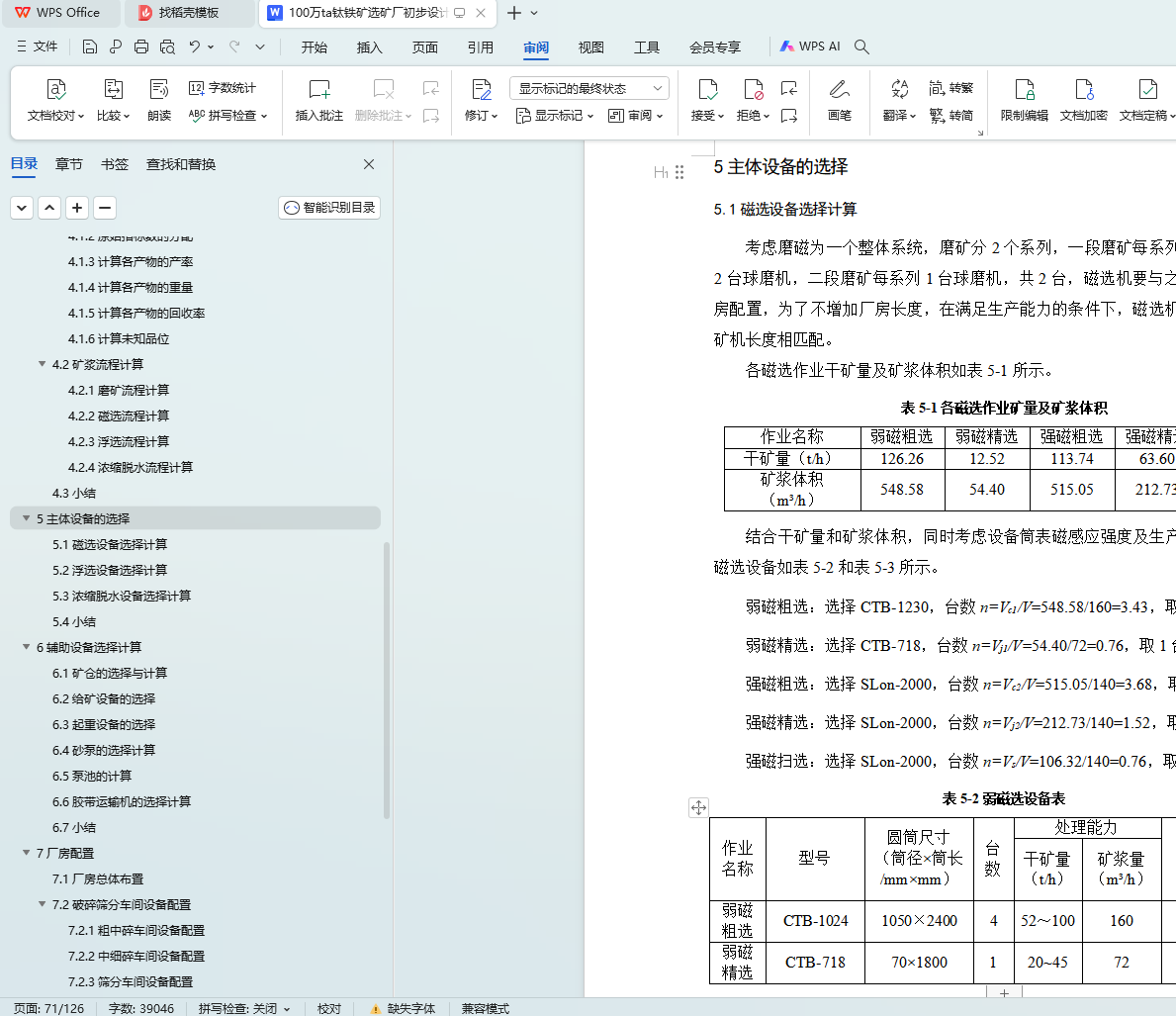

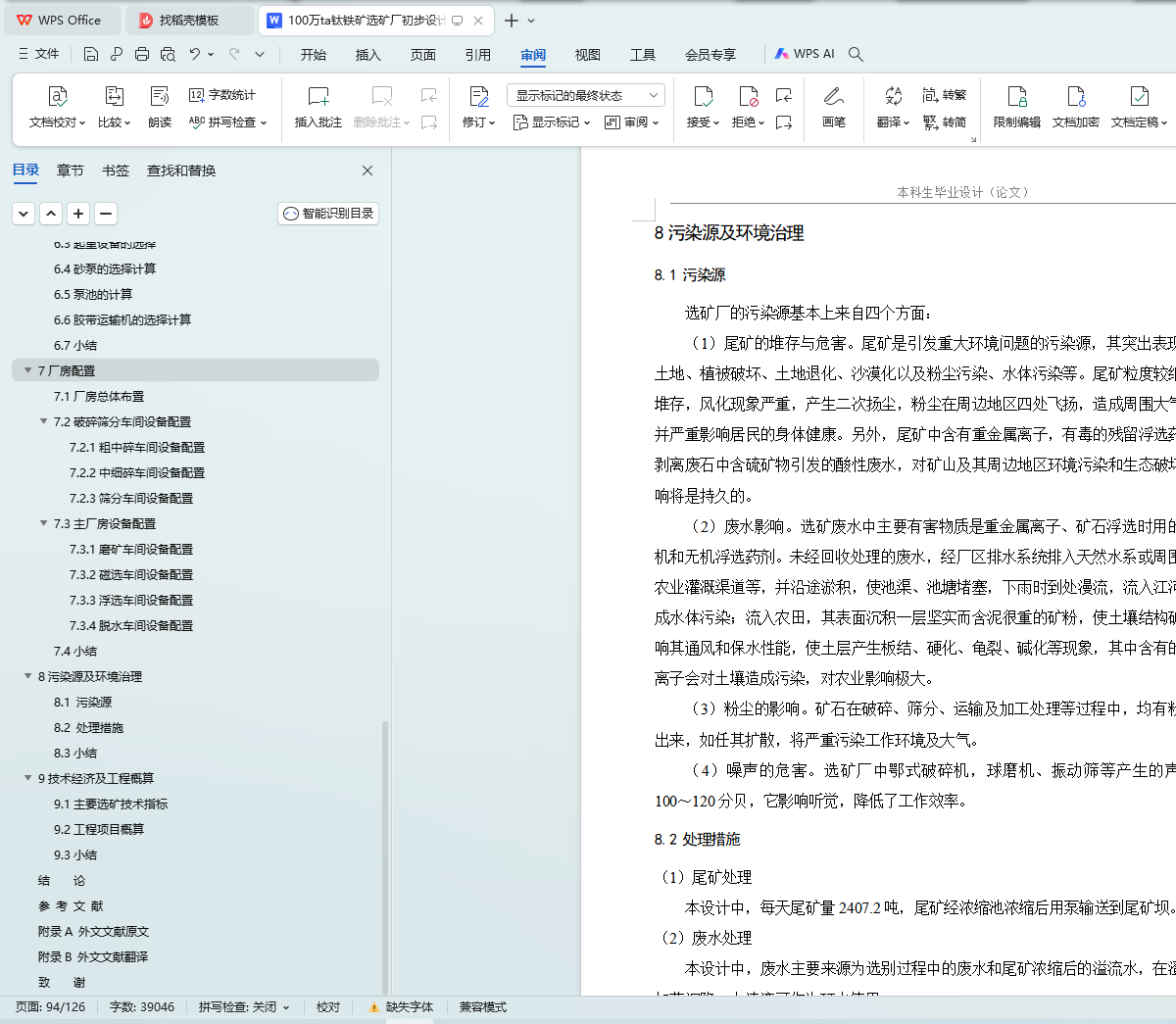

首先,通过查阅、总结相关文献,了解了目前现有的钛铁矿选别工艺以及在相关设备的应用情况。结合选矿试验结果并且借鉴现有生产实践的基础上,设计两个效果较好的破碎磨矿流程进行了技术经济方案比较,最终确定的流程为三段一闭路破碎,两段连续磨矿,磁选―浮选联合的工艺。然后,对工艺流程进行了详细计算,绘制出数质量流程图和矿浆流程图。再通过查阅资料,根据计算出的流程进行设备的选择与计算,尽量应用新型、高效的设备,使整个选厂达到设备大型化。最终,根据工艺流程以及设备选型情况完成了厂房的布置以及厂房内设备的配置,考虑到设备、厂房之间的合理紧凑,同时使矿浆能够尽可能的实现自流,将粗碎车间和筛分车间分别单设厂房,中细碎车间配置在一个厂房内,磨矿车间、磁选车间以及浮选车间配置在一个厂房内的不同平台,过滤车间也设置在主厂房,并且绘制了破碎筛分厂房、主厂房的剖面图和平面图以及选矿厂总体平面图。

关键词:钛铁矿;选矿厂设计;选别工艺;厂房布置

A preliminary design ofa ilmenite concentrator with a capacity of

one million tonsper year

Abstract

On the annual amount of 1 million tons of ilmenite processing plant preliminary design , Ilmenite is the main useful minerals of the ore ,it also contains small amounts of magnetite.

The gangue minerals are mainly quartz.Design index for the final selected other titanium concentrate grade of TiO2 is not less than 48%, the covery rate reached 60%, iron concentrate with Fe grade of not less than 62%, other impurities to meet the required quality standards.

The design includes the selection and calculation process, equipment selection and calculation, equipment configuration and plant layout, project budget etc.

First of all, through inspection, summarizes the relative literatures, the identification process of ilmenite existing at present and the application in related equipment. Combined with the mineral processing test results and referring to the existing production practice, the design of the two good application effect crushing and grinding process of the scheme comparison, eventually identified three a closed-circuit crushing, two stage continuous grinding, magnetic separation flotation combined process.

Then, the process of calculation, draw the flow chart of the number of quality and the pulp flow chart. Through access to information, complete the selection and calculation of equipment according to the calculated flow, as far as possible application of new, efficient equipment, so that the whole plant to achieve large-scale equipment.

Finally, according to the technical process and equipment type selection of complete equipment plant arrangement and plant configuration, considering the equipment, plant has the advantages of reasonable and compact, and the pulp can achieve self as far as possible, the coarsecrushing and screening workshop areseparately set up factories,andthe middle crushing and fine crushing workshop are arranged in a factory, mill ore, magnetic separation and flotation workshop are configuratedin the different platforms in a factory, filtration plant is also arranged in the main workshop,and draw the cross-sectional view and the plans of the main workshop, crushing and screening profiles and plans and the overall plan of the mineral processing plant.

Key Words:ilmenite;design of a concentrator; sorting process; plant layout

目录